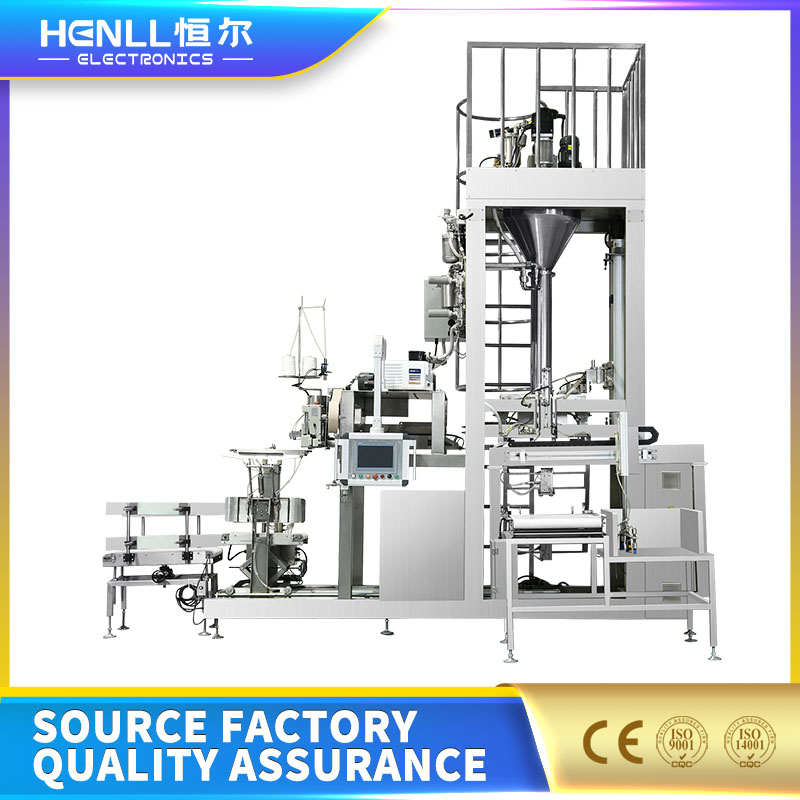

The vacuum powder packaging machine is a specialized equipment used for packaging powder materials. Its main function is to weigh and bag the powder materials in a quantitative manner. The vacuum powder packaging machine ensures the compactness of material filling through its deaeration and exhaust devices, significantly reducing the generation of dust. In the product line of Guangzhou Henll Company, there is also an option for a vacuum powder packaging machine.

Here are some detailed information about the vacuum powder packaging machine:

Ⅰ.Applications:

1.Used for large-scale quantitative weighing and bagging of powder materials.

2.Especially suitable for fine powder, ultra-fine powder, and highly adhesive powder materials.

Ⅱ.Brief description:

1.The vacuum powder packaging machine is designed specifically for ultra-fine powders that 2.tend to generate dust and materials that require high packaging accuracy.

3.Based on the signal from the weight sensor installed below the container, the equipment completes dual-speed (or triple-speed) filling, metering, and lifting operations.

4.It is suitable for packaging additives, zeolite powder, graphite powder, grout, carbon powder, fire extinguisher powder, and other ultra-fine powders, as well as materials that require high powder packaging requirements.

Ⅲ.Product features:

1.The container tray is equipped with a weight sensor, enabling fast and slow filling to ensure high packaging accuracy.

2.The tray lifting mechanism is driven by a servo motor, allowing adjustable lifting speed. During the filling process, there is minimal dust emission, avoiding environmental pollution.

3.The servo motor and servo-driven control screw provide stable performance and high accuracy.

4.PLC control and touch screen human-machine interface display make operation simple and convenient.

4.The equipment is made of stainless steel and has a modular design for easy cleaning.

5.The filling head is equipped with a hand wheel for height adjustment, enabling easy packaging of various specifications.

6.The fixed screw installation structure does not affect the properties of the material during filling.

Ⅳ.Working process:

1.Manual bagging or manual can placement.

2.Container elevation.

3.Fast filling while the container descends.

4.Weight reaches the preset value.

5.Slow filling until the weight reaches the target value.

6.Manual removal of the container.

7.Pneumatic bag clamping device or container tray device can be selected as needed to meet different canning and bagging requirements.

8.Technical parameters (HEF-50 model example):

9.Metering method: Screw filling + electronic weighing.

10.Operating interface: Touch screen human-machine interface.

11.Control circuit: PLC intelligent circuit.

12.Machine body material: Stainless steel.

13.Hopper type: Transparent bin design.

14.Hopper capacity: 50L.

15.Filling motor: Servo motor.

16.Stirring motor: Maintenance-free motor.

17.Packaging weight: Adjustable from 5kg to 25kg.

18.Packaging accuracy: ≤±10g (excluding special materials).

The vacuum powder packaging machine is a specialized equipment for packaging powder materials. It achieves deaeration and exhaust functions during the packaging process, ensuring the compactness of material filling and greatly reducing the generation of dust. Guangzhou Henll Company is a provider of vacuum powder packaging machines, and their equipment is characterized by efficiency, accuracy, and reliability.

The working principle of the vacuum powder packaging machine is to deaerate and exhaust the material during filling by using the Henll's dedicated deaeration system and exhaust device. This ensures the compactness of material filling, avoids the generation of gaps and bubbles, and improves the quality and stability of packaging. In addition, the vacuum powder packaging machine adopts a motor-driven weighing lifting mechanism, starting filling from the bottom to minimize dust emission. The negative pressure system automatically collects the trace dust generated during the filling process in the dust collector and periodically discharges it into the packaging machine hopper, achieving dust-free filling.

The vacuum powder packaging machine from Guangzhou Henll Company has the following features and advantages:

High-precision filling: The equipment uses a weight sensor for metering, ensuring accurate filling and consistent packaging.

1.Dust reduction: Through the deaeration and exhaust devices, it can significantly reduce the generation of dust and improve the cleanliness of the working environment.

2.Versatility: The equipment is suitable for packaging different specifications, with adjustable bag clamping device height to accommodate various packaging needs.

3.High efficiency and energy-saving: It adopts servo motor and servo-driven control screw, providing stable performance and efficient packaging operation while saving energy.

4.Easy operation: The equipment adopts PLC control and touch screen human-machine interface display, making operation simple and reducing the complexity of manual operation.

5.High-quality materials: The equipment is made of stainless steel, with corrosion resistance and wear resistance, and is easy to clean and maintain.

The vacuum powder packaging machine from Guangzhou Henll Company is suitable for packaging various powder materials, especially fine powder, ultra-fine powder, and highly adhesive powder. It is widely used in industries such as chemical, food, pharmaceutical, and pesticide to meet the powder packaging needs of different industries.