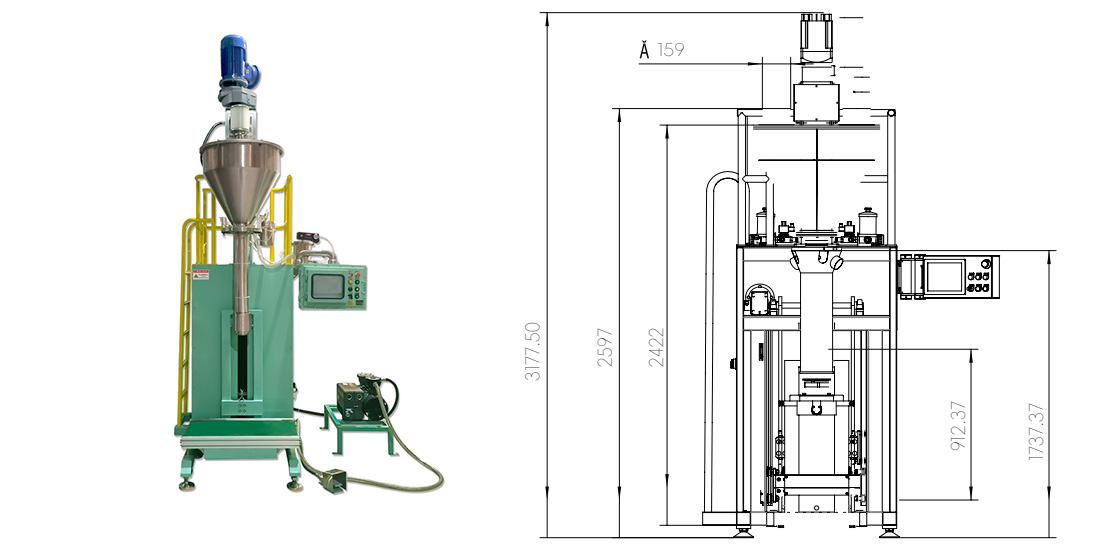

Semi-Automatic Powder-Filling Packaging Machine

Semi-Automatic Powder-Filling Packaging Machine Features

1.High precision: international advanced sensors are used to adjust the filling speed quickly and slowly according to the preset weight, so as to ensure high packaging precision.

2.Low dust: The patented degassing and feeding system is adopted to basically discharge all the air in the material during filling, and no dust is raised to avoid environmental pollution.

3.High efficiency: the use of servo motor and servo drive control screw, to achieve rapid, high-precision filling.

4.Easy to operate: PLC control system with touch screen man-machine interface display, making the operation simple and easy to understand.

5.Easy to clean: all stainless steel structure design, combined bin, making the cleaning process is very convenient.

6.Multi-specification: The height of the filling head can be adjusted freely to meet the packaging requirements of various specifications.

7.Stable filling: fixed screw installation structure ensures that the filling process will not affect the nature of the material.

Semi-Automatic Powder-Filling Packaging Machine Specification

| Project | Classification | |

| Filling Function: | Optional: Degassing Model | Optional: Non-Degassing Model |

| Material: | Optional: Full Stainless Steel, 304L/316L | Optional: Machine Body Part with Sprayed Carbon Steel |

| Explosion-Proof: | Optional: Explosion-Proof Model | Optional:Non-Explosion-Proof Model |

| Load Cell (Weighing Sensor) | Optional: Aviation Electronics Measurement/Ningbo Keli (Weighing Sensor Brands) | Optional:Mettler Toledo (Weighing Sensor Brand) |

| Hardening: | Optional:Sprayed with Teflon Coating | Optional: Sprayed with Tungsten Carbide Coating |

| Hopper Capacity: | Optional: 80L Capacity | Optional:120L Capacity |

| Filling Accuracy: | Optional: Standard Model with ±50g Accuracy | Optional: High Precision Model with +20g Accuracy |

| Filling Speed: | Optional: Standard Model with 40 Bags/Hour | Optional: High-Speed Model with 90 Bags/Hour |

Overall Machine Power: | Approximate Power:6KW | |

Semi-Automatic Powder-Filling Packaging Machine of Configuration

The Henll powder packaging machine is suitable for packaging various ultra-fine powdered materials, such as:

Chemical industry: rubber powder, pigment, dye, coating, catalyst, cosmetics raw materials, etc.

Food industry: flour, starch, sugar powder, coffee powder, seasoning powder, etc.

Pharmaceutical industry: Chinese medicine powder, Western medicine powder, API, etc.

Metallurgical industry: metal powder, alloy powder, etc.

New materials industry: nanomaterials, graphene powder, polymer materials powder, composite materials powder, metal oxide powder, etc.

New energy industry: lithium battery material powder, such as cathode materials (such as lithium iron phosphate, lithium cobalt oxide, etc.) and anode materials (such as graphite, silicon, etc.); solar cell material powder, such as silicon powder, germanium powder, etc., used to manufacture solar cells; fuel cell material powder, such as catalyst powder (such as platinum, palladium, etc.); supercapacitor material powder, such as activated carbon powder, ruthenium oxide powder, etc.

Semi-Automatic Powder-Filling Packaging Machine Product Detailed

Self-returning degassing and dust removal mechanism

The Henll patent degassing device can effectively remove the gas generated during material packaging and has the function of dust prevention. It can reduce environmental pollution while improving production efficiency and product quality. The dust removal and filtration device can filter out dust and particulate matter, making the working environment cleaner and protecting the health of workers.

Semi-Automatic Powder-Filling Packaging Machine Product Description

Function introduction:1. that air in the fine pow is removed by a degassing device, the compactness aft the material is filled is ensured, and the material precipitation process is reduce. 2.remove air in that fine powder, ensure that the discharge port is filled into the bag in a cluster state, and greatly reducing dust.

3. a tungsten carbide spray process can be adde to that spiral part, so that the possibility of bringing foreign matters into the material is reduced.

4.The servo motor drives the tray to lift, and the lifting height and speed can be set arbitrarily to reduce the fall between the filling port and the material surface and reduce the dust.

5. collect a trace amount of floating dust by that dust removal recycle negative pressure cover to realize dust-free filling process.

6.The degassing leak-proof valve ensures that the superfine powder does not drip.

7.The weight sensor under the container tray controls the fast and slow filling to ensure high packaging accuracy.

8.Servo motor and servo drive control screw, with stable performance and high precision.

9.PLC control, touch screen man-machine interface display, easy to operate.

10. The filling head is equipped with a hand wheel to adjust the height, which can easily realize the packaging of various specifications.

11.Fixed screw installation structure does not affect the material properties.

Semi-Automatic Powder-Filling Packaging Machine Construction

It mainly consists of: a fully sealed storage bin (120L), power stirring mechanism, column, metering screw, special degassing device, electrical automation control part, high-precision weighing system, special bag clamp (adjusted according to the container), dust collection and recycling negative pressure cover, lifting device, enhanced sealing parts, nano degassing system, and complex weighing system.