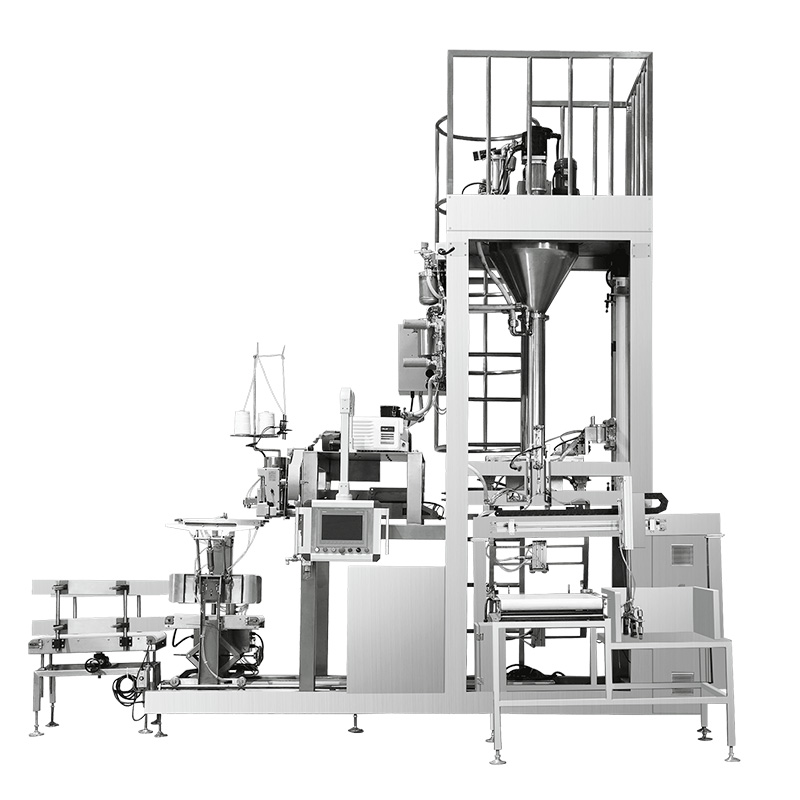

Full-Automatic Powder Sewing Bag Filling And Packaging Machine

Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine Features

The fully automatic powder sewing bag filling and packaging machine is an advanced packaging equipment with multiple unique product features. Here are some of its main characteristics:

Automation: The fully automatic powder sewing bag filling and packaging machine uses an advanced automation control system to achieve the automation of the entire packaging process, from filling to sealing, without the need for manual intervention. This improves production efficiency and reduces labor costs.

High-precision filling: The equipment is equipped with a precise filling system that can accurately control the weight or volume of each bag of product based on the set filling amount. This ensures consistency in the filling quantity of each bag, thereby improving product quality and consistency.

Versatility: The fully automatic powder sewing bag filling and packaging machine is suitable for the packaging of various powdered materials, such as new energy materials, new materials, food powders, cosmetic powders, pharmaceutical powders, and more. It can adapt to different bag types and packaging specifications, demonstrating strong adaptability and flexibility.

Quick adjustment and changeover: The equipment is ingeniously designed and easy to adjust and changeover, allowing for quick adaptation to different bag and product specifications. This facilitates convenient switching of production lines, reduces production downtime, and improves production efficiency.

Reliable stability: The fully automatic powder sewing bag filling and packaging machine adopts high-quality components and a stable mechanical structure to ensure the reliability and stability of the equipment. It can operate stably for long periods, reducing the possibility of failures and improving production efficiency and production line stability.

In conclusion, the fully automatic powder sewing bag filling and packaging machine, with its features of automation, high-precision filling, versatility, quick adjustment and changeover, as well as reliable stability.

Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine Specification

| Project |

| Packing speed :40-60 bags/hour, 25KG |

| Packaging accuracy:±50g/ bag,25KG |

| Online automatic weighing accuracy :±50g/ bag |

| Can automatically and flexibly call the pre-set parameters of the production material classification, record the productionprocess information, can be traced to the system, can be printed, uploaded and saved. |

| Applicable packing material form: aluminum crack film/kraft paper inner film bag/composite film bag/pure PE bag |

| Applicable packing form category :M bag, flat pocket |

| Applicable packing size range: width :400mm--600mm, height: 600mm 1100mm |

| The minimum vacuum degree of the bag is -70KPA |

| The size range of bags in the vacuum box is to be determined, and the length and width adjustment range is to be determined(to change according to the demand of different sizes of bags)i0 bag sforage bag quantity requirement :60 (to meet the different bag thickness) |

Henll Full-Automatic Powder Filling And Packaging Machine Range Of Configuration

The Henll powder packaging machine is suitable for packaging various ultra-fine powdered materials, such as:

Chemical industry: rubber powder, pigment, dye, coating, catalyst, cosmetics raw materials, etc.

Food industry: flour, starch, sugar powder, coffee powder, seasoning powder, etc.

Pharmaceutical industry: Chinese medicine powder, Western medicine powder, API, etc.

Metallurgical industry: metal powder, alloy powder, etc.

New materials industry: nanomaterials, graphene powder, polymer materials powder, composite materials powder, metal oxide powder, etc.

New energy industry: lithium battery material powder, such as cathode materials (such as lithium iron phosphate, lithium cobalt oxide, etc.) and anode materials (such as graphite, silicon, etc.); solar cell material powder, such as silicon powder, germanium powder, etc., used to manufacture solar cells; fuel cell material powder, such as catalyst powder (such as platinum, palladium, etc.); supercapacitor material powder, such as activated carbon powder, ruthenium oxide powder, etc.

Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine Product Detailed

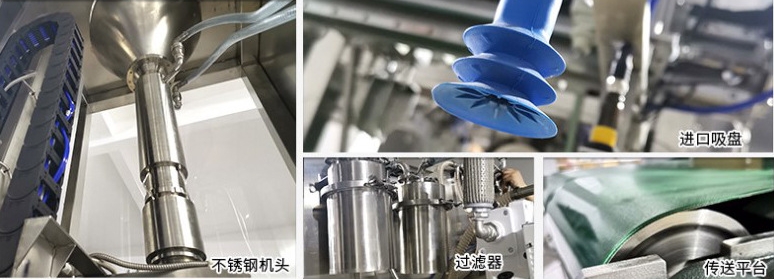

1. By utilizing advanced materials, manufacturing processes, and incorporating international advanced technologies, the bag's adhesion capabilities are enhanced, resulting in stronger, more precise, durable, and reliable performance.

2. Henll's patented degassing device efficiently removes gases generated during the material packaging process while also providing dust-proof functionality. It not only reduces environmental pollution but also improves production efficiency and product quality.

Full-Automatic Powder Sewing Bag Filling And Packaging Machine Product Detailed

Henll Full-Automatic Powder Filling And Packaging Machine Product Description

The Full-Automatic Powder Sewing Bag Filling And Packaging Machine is an advanced packaging equipment specifically designed for filling and packaging powdered products. It has several important product features:

Efficient filling: This equipment utilizes an automated control system to achieve efficient powder filling. Through precise metering and control, it ensures accurate filling quantity for each bag, thereby improving production efficiency and product consistency.

Multifunctional operation: The fully automatic powder sewing bag filling and packaging machine offers various operational functions to accommodate different bag sizes and shapes, including sewing bags, vertical bags, and more. It is also suitable for different types of powdered products such as food, cosmetics, pharmaceuticals etc..

Flexible adjustment: The equipment is designed with flexibility, allowing for quick adjustment and changeover. Users can easily adjust and set the filling quantity and packaging requirements to meet different product and production needs.

High-precision control: The fully automatic powder sewing bag filling and packaging machine is equipped with a precise weight or volume control system to accurately control the filling quantity of each bag. Advanced sensors and control technology ensure the accuracy and consistency of the filling quantity for each bag.

Reliable stability: The equipment adopts high-quality components and a stable mechanical structure to ensure reliability and stability. It can operate stably for extended periods, reducing the possibility of failures and improving production efficiency and line stability.

Henll's Full-Automatic Powder Sewing Bag Filling And Packaging, with its features of efficient filling, multifunctional operation, flexible adjustment, high-precision control, and reliable stability, is an ideal choice for powdered product packaging. It helps businesses improve production efficiency, reduce costs, and ensure product quality and consistency.

Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine Construction

Henll's Full-Automatic Powder Sewing Bag Filling And Packaging Machine is a complex and precision equipment designed to achieve efficient filling and packaging processes. Here is an explanation of its structural components:

Frame structure: The equipment is built with a sturdy and reliable frame structure to ensure stability and support. The frame is typically made of high-quality steel, providing excellent corrosion resistance and durability.

Filling system: The fully automatic powder sewing bag filling and packaging machine is equipped with an advanced filling system, including a hopper, conveying device, and filling head. The powder is stored in the hopper, conveyed to the filling head through the conveying device, and then accurately filled into the bags. The filling system usually consists of precise metering devices and control systems to ensure accurate filling quantities for each bag.

Sealing system: The sealing system of the equipment is responsible for sealing the filled bags. The sealing method can be selected according to requirements, with common options being heat sealing and sewing. The sealing system typically includes heating elements, sealing blades, and pressure control systems to ensure secure and well-sealed bags.

Control system: The fully automatic powder sewing bag filling and packaging machine is equipped with an advanced control system to enable automated operation and precise control. The control system usually includes a touchscreen interface and a PLC controller, allowing for easy setting of filling quantities, adjustment of filling speeds, and monitoring of equipment operation status.

Safety devices: To ensure the safety of operators, the fFull-Automatic Powder Sewing Bag Filling And Packaging Machine is typically equipped with various safety devices such as safety doors, emergency stop buttons, and protective covers. These devices can promptly detect and respond to potential safety risks, ensuring the personal safety of operators.