Semi-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine

Henll Powder Bulk Bag Filling And Jumbo Bag Packaging Machine Features

The Powder Bulk Bag Filling And Jumbo Bag Packaging Machine is a powerful and efficient device specifically designed for vacuum packaging large bag products. Here are several prominent features of this product:

Efficient degassing: The large bag vacuum packaging machine utilizes advanced degassing technology, allowing for quick and thorough removal of air from the material during the packaging process. This effectively extends the product's shelf life and enhances material density.

Versatile operation: The equipment offers various operational functionalities, making it suitable for different sizes and shapes of large bag products. Whether it is powder or granules, it can easily undergo degassing packaging, catering to the needs of different industries and products.

Precise control: The large bag vacuum packaging machine is equipped with a precise control system that enables accurate packaging parameter settings and adjustments. Users can flexibly adjust packaging speed, pressure, and degassing time according to product requirements, ensuring optimal packaging results.

High production efficiency: With its high-speed packaging capability and stable production performance, the equipment can swiftly and continuously complete degassing packaging tasks for large bag products. This significantly enhances production efficiency and capacity while reducing labor costs.

Quality assurance: The large bag vacuum packaging machine is manufactured using high-quality materials and advanced manufacturing processes, ensuring equipment stability and durability. It undergoes rigorous quality inspections and testing to guarantee product quality and reliability.

Henll Powder Bulk Bag Filling And Jumbo Bag Packaging Machine Specification

| Project |

| Measuring method: Electronic weighing from above. (hook weighing) |

| Main body material: The main frame is carbon steel with baked paint, and the part in contact with materials is stainless steel, grade 304 |

| Silo volume:280lL |

| Packaging weight (range):100~1000KG (adjustable) |

| Feeding accuracy:±500g(based on 500kg/bag) |

| Dust removal system: quipped with a top-mounted dust colector to collect materials during the packaging process, which can automatically recycle into the silo;,filtration accuracy:0.5um,automatic pulse cleaning; |

| Bag clamping method: Rubber airbag clamping |

| Degassing function: Vertical degassing spiral |

Henll Powder Bulk Bag Filling And Jumbo Bag Packaging Machine Range Of Configuration

The chemical industry: The large bag vacuum packaging machine is widely used in the chemical industry for packaging chemical products in the form of powder, granules, or liquids. Whether it's plastic particles, fertilizers, pigments, or powdered additives, catalysts, etc., this equipment can effectively vacuum package them, extending the shelf life and quality assurance of the products.

The food industry: The food industry is also an important application field for the large bag vacuum packaging machine. This equipment is suitable for packaging large bags of food products such as grains, beans, dried fruits, seasonings, flour, starch, powdered sugar, coffee powder, seasoning powder, etc. Through vacuum packaging, it can effectively removes air and maintain the freshness and taste of food.

The pharmaceutical industry: In the pharmaceutical industry, the large bag vacuum packaging machine can be used for packaging large bags of pharmaceutical raw materials, powders, and formulations. Vacuum packaging can effectively protect the active ingredients of drugs, extend their shelf life, and ensure the quality and stability of the drugs.

The new materials industry: The large bag vacuum packaging machine is also suitable for packaging new materials such as nano materials, graphene powder, polymer material powder, composite material powder, metal oxide powder, etc.

The new energy industry: For materials used in the new energy industry, the large bag vacuum packaging machine can be used for packaging lithium battery materials, such as cathode materials (e.g., lithium iron phosphate, lithium cobalt oxide, etc.) and anode materials (e.g., graphite, silicon, etc.), solar cell materials such as silicon powder, germanium powder, etc., and fuel cell materials such as catalyst powders (e.g., platinum, palladium, etc.).

The construction materials industry: The demand for the large bag vacuum packaging machine in the construction materials industry is also significant. This equipment can be used for packaging building materials such as cement, gypsum, sand, etc. Vacuum packaging can reduce the moisture content in the building materials and improve the quality and stability of the materials.

Other industries: In addition to the above-mentioned industries, the large bag vacuum packaging machine is also suitable for packaging other large bag products such as animal feed, cosmetic raw materials, industrial raw materials, etc. Its multifunctional operation and flexibility make it an ideal choice to meet the needs of different industries and products.

Henll Powder Bulk Bag Filling And Jumbo Bag Packaging Machine Product Detailed

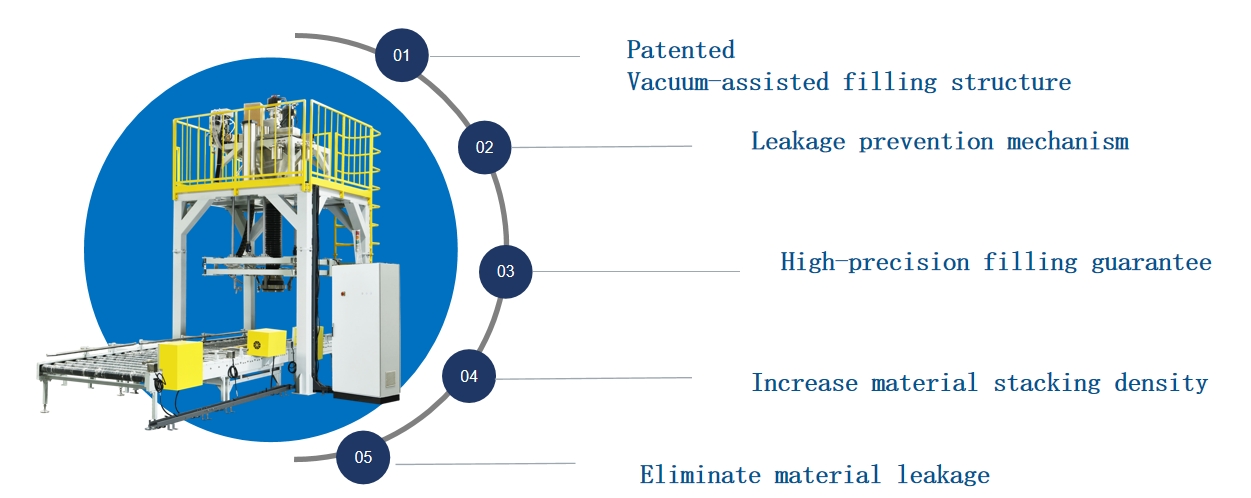

Specialized degassing device(Patent number: ZL 201620413233.9)

The degassing device can remove the air contained in the ultra-fine powder material, ensuring that the material at the discharge port is filled into the bag in a clustered state. This significantly reduces dust and allows more material to be packed into the bag.

Henll Semi-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine Product DescriptionThe degassing effect is excellent: Powder Bulk Bag Filling And Jumbo Bag Packaging Machine uses highly efficient patented degassing technology, which can quickly remove air from the material in the discharge. This degassing effect is outstanding and can significantly extend the product's shelf life while maintaining its quality.

Multi-functional operation: This equipment has multiple operation functions, allowing it to adapt to different sizes and shapes of large bag products. Whether it is powder or granules, degassing packaging can be conveniently carried out. In addition, the equipment also has adjustable packaging speed, pressure, and degassing time to meet the packaging requirements of different products.

Precise control system: Powder Bulk Bag Filling And Jumbo Bag Packaging Machine is equipped with a precision control system, allowing users to accurately set and adjust the packaging parameters according to product requirements. This precise control ensures the stability and consistency of each packaging process, improving packaging effectiveness and product quality.

High production capacity: This equipment has high-speed packaging capability and stable production performance, enabling quick and continuous completion of degassing packaging tasks for large bag products. This greatly improves production efficiency and capacity, reducing labor costs.

Quality assurance: Powder Bulk Bag Filling And Jumbo Bag Packaging Machine is made of high-quality materials and advanced manufacturing processes to ensure equipment stability and durability. It undergoes strict quality inspection and testing to ensure product quality and reliability.

Henll Powder Bulk Bag Filling And Jumbo Bag Packaging Machine ConstructionDust removal mechanism: The dust collection negative pressure hood collects trace floating dust, achieving a dust-free filling process.

Discharge bin: The packaging machine's buffer bin uses a weighing bin control system to accurately control the material level.

Discharge screw: The degassing device removes air from the fine powder, ensuring compactness of the material after filling and reducing material settling process.

Lifting mechanism: Automatically lifts the ton bag to the height of the discharge mechanism based on the filling situation, suppressing dust emissions.

Bag clamping device: Inflatable bag clamping mechanism prevents material from spilling or foreign objects from entering during the discharge process.

Control cabinet: Professional industrial-grade control cabinet.

Re-weighing system: Automatic re-weighing system checks packaging accuracy and improves packaging quality.

Conveyor roller: Used for outputting the filled ton bag or connecting to the next process, reducing manual labor intensity.