Full-Automatic Powder Filling And Packaging Machine

Henll Full-Automatic Powder Filling And Packaging Machine Features

1.High degree of automation: The fully automatic powder vacuum packaging machine can achieve fully automatic operation without human intervention, and can be used for degassing and automatic vacuum sealing, thereby improving production efficiency and reducing labor costs.

2.Accurate weighing system: The fully automatic powder vacuum packaging machine is equipped with an accurate weighing system, which can accurately weigh the weight of powder products to ensure packaging accuracy and consistency.

3.Fast packaging: The fully automatic powder vacuum packaging machine can achieve fast packaging, packaging up to dozens of bags of powder products per minute, which can improve production efficiency and reduce waiting time.

4.Easy to clean: The fully automatic powder vacuum packaging machine adopts a closed packaging method, which can reduce the flying and pollution of powder products, and the cleaning of the equipment is also very convenient, which can improve the health level of the production environment.

5.Multiple packaging forms: The fully automatic powder vacuum packaging machine can provide multiple different packaging forms according to customer needs, such as plastic bags, aluminum foil bags, composite bags, paper bags, etc., to meet different market needs.

6.High vacuum degree: The fully automatic powder vacuum packaging machine adopts a fully automatic high vacuum degree system, which can achieve high-quality vacuum packaging, effectively preventing powder products from oxidation, moisture and deterioration.

Henll Full-Automatic Powder Filling And Packaging Machine Specification

| Project |

| Packing speed :40-60 bags/hour, 25KG |

| Packaging accuracy:+50g/ bag,25KG |

| Online automatic weighing accuracy :+50g/ bag |

| Can automatically and flexibly call the pre-set parameters of the production material classification, record the productionprocess information, can be traced to the system, can be printed, uploaded and saved. |

| Applicable packing material form: aluminum crack film/kraft paper inner film bag/composite film bag/pure PE bag |

| Applicable packing form category :M bag, flat pocket |

| Applicable packing size range: width :400mm--600mm, height: 600mm 1100mm |

| The minimum vacuum degree of the bag is -70KPA |

| The size range of bags in the vacuum box is to be determined, and the length and width adjustment range is to be determined(to change according to the demand of different sizes of bags)i0 bag sforage bag quantity requirement :60 (to meet the different bag thickness) |

HENLL Full-Automatic Powder Filling And Packaging Machine Range Of Configuration

The Henll powder packaging machine is suitable for packaging various ultra-fine powdered materials, such as:

Chemical industry: rubber powder, pigment, dye, coating, catalyst, cosmetics raw materials, etc.

Food industry: flour, starch, sugar powder, coffee powder, seasoning powder, etc.

Pharmaceutical industry: Chinese medicine powder, Western medicine powder, API, etc.

Metallurgical industry: metal powder, alloy powder, etc.

New materials industry: nanomaterials, graphene powder, polymer materials powder, composite materials powder, metal oxide powder, etc.

New energy industry: lithium battery material powder, such as cathode materials (such as lithium iron phosphate, lithium cobalt oxide, etc.) and anode materials (such as graphite, silicon, etc.); solar cell material powder, such as silicon powder, germanium powder, etc., used to manufacture solar cells; fuel cell material powder, such as catalyst powder (such as platinum, palladium, etc.); supercapacitor material powder, such as activated carbon powder, ruthenium oxide powder, etc.

Advanced bag feeding system

By using advanced materials and manufacturing techniques and referring to international advanced technologies, the bag adsorption capacity is stronger, more accurate, more durable, and more reliable.

The Henll patented degassing device can efficiently remove the gas generated during material packaging while having a dustproof function. It can not only reduce environmental pollution but also improve production efficiency and product quality.

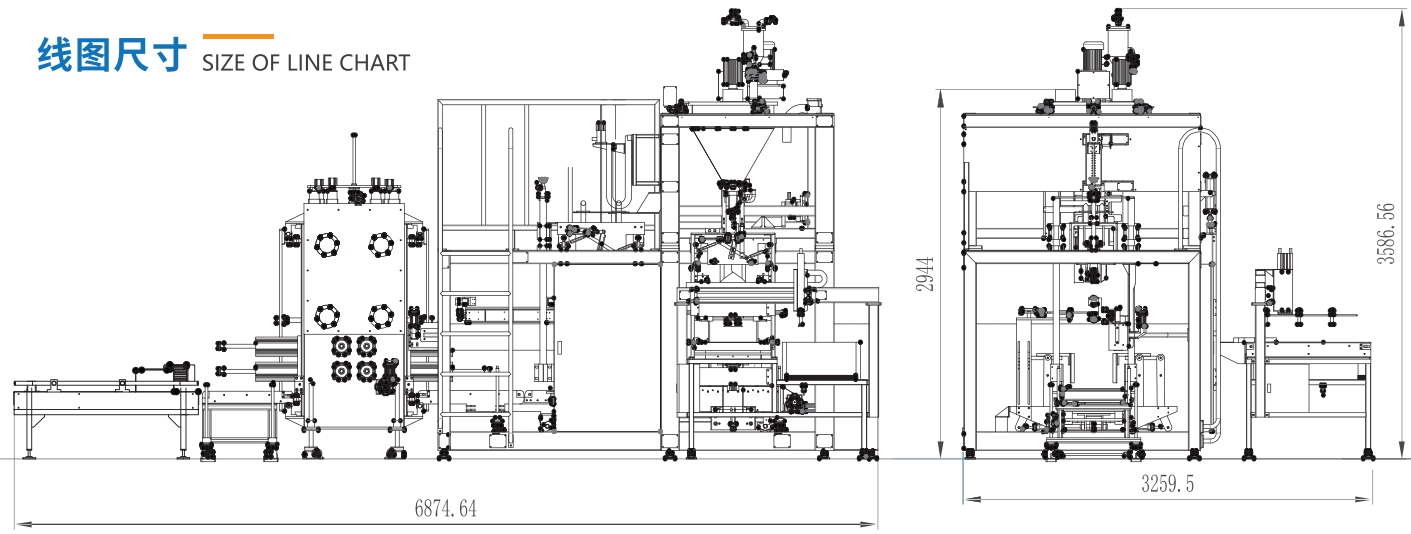

Henll Full-Automatic Powder Filling And Packaging Machine Product Description

The Henll fully automatic powder packaging machine can help enterprises achieve fully automatic quantitative filling, packaging, and vacuum integration. Starting from the hopper discharge port of the sieve section piping conveying system, it is connected to the automatic packaging machine and the automatic vacuum heat sealer. It automatically realizes all the processes of finished packaging, including automatic bag feeding, automatic bag opening, automatic quantitative feeding, automatic weighing, automatic vacuuming, automatic heat sealing, and other integrated packaging equipment.

Henll Full-Automatic Powder Filling And Packaging Machine Construction

Henll full-automatic powder filling and packaging machine is a fully automated packaging equipment that combines functions such as degassing, vacuuming, and sealing, allowing for the automated packaging of powdered products. It consists of the following components:

Deaeration system: Composed of degassing devices and valves, it is used to remove gas from the packaging bag, preventing powder from clumping and extending the product's shelf life.

Vacuum system: Comprising a vacuum pump, vacuum valves, and vacuum gauge, it generates and maintains the vacuum level inside the packaging bag, preventing powder leakage.

Sealing system: Consisting of a sealing machine and sealing film, it is used to seal the packaging bag, ensuring its airtightness.

Control system: Composed of a PLC and touch screen, it enables the automation control of the equipment, improving production efficiency and packaging quality.

Feeding system: Consisting of a hopper and screw feeder, it automatically fills the packaging bag with powdered products, enhancing packaging efficiency.

Dust removal system: Comprising a vacuum cleaner and dust filters, it filters out dust and particles generated during the packaging process, ensuring a clean working environment.

These components work together to enable the automated operation of the fully automatic powder degassing, vacuuming, and sealing packaging machine, thereby improving production efficiency and packaging quality.