Choosing the right Chemical Powder Packaging Machine maker is important for safety and working well. Henll is special because it has a Fully Automatic Ton Bag Packaging Machine (100-1000KG). This machine uses smart weighing tools and safe sealing to keep powders and granules safe. Henll’s design helps companies waste less and work faster. Many companies trust Henll because it is strong and has quick customer help. Buyers should look at what they need and see if Henll or other top brands have those features.

Key Takeaways

Picking the right packaging machine is very important for safety and working well. Henll's Fully Automatic Ton Bag Packaging Machine packs things quickly and very accurately. This makes it a favorite for many businesses. Think about what you need, like the size of the bag and the kind of product, before you choose a packaging machine. Find machines that have good customer support and help after you buy them. This will help your work go smoothly. New machines with automation can help stop mistakes and help you work faster. Check what the machine is made of to make sure it is strong and lasts a long time. People who use these machines say it is important that they are easy to use and work well. Buying good machines can help you save money later by making less waste and needing fewer repairs.

Top 10 Manufacturers

Henll Chemical Powder Packaging Machine

Company Overview

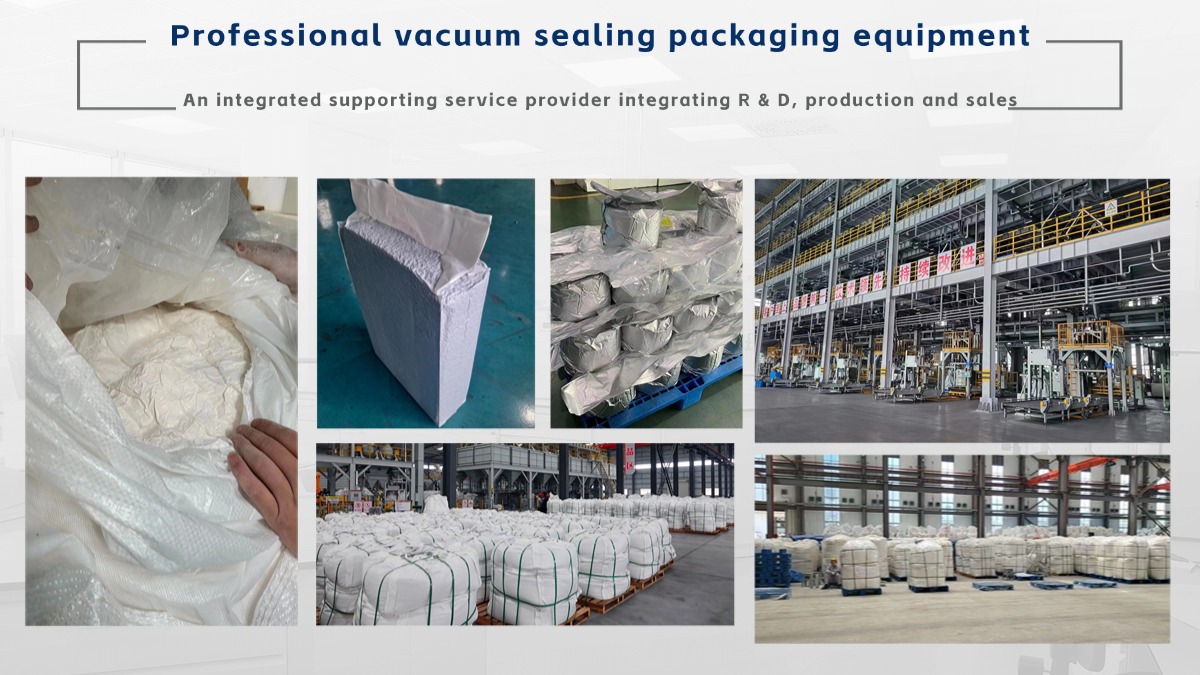

Henll is a well-known company in packaging. They make machines for powders and granules. People trust Henll because their machines work well. Henll always tries to make new and better machines. Their customer support is strong and helpful. Many businesses pick Henll for quality and safety. Their machines help companies work faster and safer.

Fully Automatic Ton Bag Packaging Machine (100-1000KG)

Henll has a machine for big bags. It can fill bags from 100 to 1000 kilograms. The machine uses electronic weighing for accuracy. Workers use a touch screen to control it easily. The heat sealing strip keeps each bag closed tight. This stops contamination. The frame is made of carbon steel. The platform panel is made of stainless steel. The machine packs one bag every eight minutes. This saves time and labor. A dust remover keeps the area clean. It also helps seal bags better. The machine works for powders and granules. It is used in chemicals, building materials, grains, and new energy.

Key Features & Benefits

Electronic weighing is very accurate (±50 grams)

Touch screen controls are easy to use

Heat sealing makes bags strong and safe

Carbon steel and stainless steel make it tough

Fast packing helps companies do more work

Dust remover keeps the area clean

Stops oxidation, moisture, and mold

Lowers the chance of contamination and bad smells

Makes moving and handling bags safer

Quick help after buying the machine

Tip: Henll’s machine helps keep products safe and fresh. It also makes storage and transport easier.

Customer Feedback

Customers say Henll’s machines are easy to use. They have fewer losses and pack faster. The support team helps quickly when there are problems. This keeps production going well. Many companies trust Henll for good results and strong packaging.

Shemesh Automation

Company Overview

Shemesh Automation is a top company for packaging machines. They make machines for powders, liquids, and solids. Shemesh Automation is known for new ideas and high quality. Their machines are used in chemicals, food, and medicine.

Key Products

Powder Filling Machines

Bagging Systems

Sealing and Capping Machines

Unique Features

Shemesh Automation uses smart automation in their machines. They offer machines that fit different needs. Their machines measure doses very well. The machines are built strong. Shemesh Automation can make special machines for clients.

Customer Feedback

Customers like that Shemesh Automation’s machines are reliable. They fit easily with other machines in factories. The support team is fast and helpful.

Finopack

Company Overview

Finopack makes machines for powders and granules. They focus on making machines that work fast and save money. Finopack helps companies in chemicals, food, and farming.

Key Products

Vertical Form Fill Seal Machines

Auger Filling Machines

Bagging Systems

Unique Features

Finopack machines work quickly and fill bags accurately. They use new technology for better packaging. The controls are simple to use. The sealing system is strong. Finopack offers different bag sizes and materials.

Customer Feedback

Customers like Finopack’s machines because they are fast and reliable. They need less fixing and work well all the time. The support team helps solve problems quickly.

All-Fill

Company Overview

All-Fill began in the United States. They make machines for filling powders, granules, and liquids. Their equipment is known for being reliable. Many businesses use these machines in food, chemicals, and medicine.

Key Products

Auger Fillers

Volumetric Cup Fillers

Vibratory Fillers

Checkweighers

Unique Features

All-Fill machines measure powders very accurately. Their auger fillers use smart controls for exact dosing. The company has machines for many bag sizes and shapes. All-Fill uses stainless steel to make their machines strong. Their machines can work with automatic bagging systems.

Note: All-Fill gives training and support so customers use machines well.

Customer Feedback

Customers say All-Fill machines are simple to set up and use. Many people have fewer breakdowns and less fixing. The support team answers questions fast. Companies trust All-Fill for steady performance.

Premier Tech

Company Overview

Premier Tech is a worldwide company from Canada. They make packaging machines for powders, granules, and bulk items. Premier Tech has helped chemical, food, and farm businesses for years.

Key Products

Bagging Machines

Palletizers

Weighing Systems

Robotic Packaging Solutions

Unique Features

Premier Tech uses smart technology in their machines. Their systems fill and seal bags quickly. The company has machines for many bag types, like valve bags and open-mouth bags. Premier Tech builds equipment that connects with other factory machines. Their machines help lower dust and keep work areas clean.

Tip: Premier Tech makes custom machines for special packaging needs.

Customer Feedback

Customers like Premier Tech for strong machines and fast help. Many people say the machines help them pack faster. The company gives good training and technical support. Premier Tech is known for being reliable.

Viking Masek

Company Overview

Viking Masek is a packaging machine maker from the United States. They make machines for powders, liquids, and solids. Viking Masek helps companies in chemicals, food, and pet care.

Key Products

Vertical Form Fill Seal Machines

Rotary Fillers

Sachet Packaging Machines

Stick Pack Machines

Unique Features

Viking Masek makes machines that work fast and fill bags well. Their equipment uses touch screens for easy control. The company has machines for many bag styles, like pouches and stick packs. Viking Masek uses strong materials so machines last longer. Their systems can have automatic weighing and sealing.

Tip: Viking Masek gives online guides and videos to help customers learn.

Customer Feedback

Customers say Viking Masek machines are flexible and simple to use. Many people have fewer mistakes and smooth running. The support team helps with setup and fixing problems. Viking Masek is praised for helpful service and strong machines.

PAYPER

Company Overview

PAYPER began in Spain. They make machines for packing powders and granules. Their machines also pack bulk materials. PAYPER works with chemical, food, and building companies. People know PAYPER for strong and good machines. The company helps customers make packaging better.

Key Products

Bagging Machines for powders and granules

Weighing and dosing systems

Palletizing solutions

Automatic and semi-automatic bagging lines

Unique Features

PAYPER’s machines fill bags fast and correctly. Their systems use smart weighing tools. The machines work with many bag types. These include valve bags and open-mouth bags. PAYPER gives choices for different needs. Their controls are simple. The machines have good safety features.

Tip: PAYPER’s machines help companies waste less and keep products safe.

Customer Feedback

Customers say PAYPER’s machines are simple to use. Many people have fewer mistakes and pack faster. The support team answers quickly. PAYPER gets praise for strong machines and good help.

Webster Griffin

Company Overview

Webster Griffin is from Britain. They make machines for packing powders and granules. Their machines also pack bulk items. Webster Griffin helps chemical, food, and mineral companies. The company has lots of experience in packaging.

Key Products

Big bag filling machines

Valve sack filling systems

Form fill seal machines

Palletizing and stretch wrapping equipment

Unique Features

Webster Griffin’s machines fill big bags very well. Their systems use electronic weighing and automatic controls. The machines can pack many kinds of powders and granules. Webster Griffin makes special machines for different needs. They use strong materials for long-lasting equipment.

Note: Webster Griffin gives training and support so customers use machines well.

Customer Feedback

Customers trust Webster Griffin for tough and steady machines. Many people say the machines run smoothly and need little fixing. The support team helps with setup and repairs. Webster Griffin gets good reviews for service and quality.

Concetti

Company Overview

Concetti is from Italy. They design and build machines for packing powders and granules. Their machines also pack bulk materials. Concetti helps chemical, food, and farm companies. People know Concetti for new ideas and strong machines.

Key Products

Automatic bagging machines

Weighing and dosing systems

Palletizers

Bag closing and sealing machines

Unique Features

Concetti’s machines fill and seal bags with care. Their systems use smart automation and weighing tools. The machines work with many bag sizes and types. Concetti gives choices for different production lines. The company cares about safety and easy use.

Tip: Concetti’s machines help companies pack faster and keep products safe when moving.

Customer Feedback

Customers say Concetti’s machines are easy to set up and use. Many people have fewer breakdowns and smooth working. The support team answers fast. Concetti gets praise for strong machines and good service.

PT Chronos

Company Overview

PT Chronos is a top company in packaging technology. They have helped many industries for a long time. Their machines work for powders, granules, and bulk materials. Chemical, food, and mineral companies use their machines. PT Chronos is known for new ideas and good quality. Many people trust them because they do a great job.

Key Products

Automatic bagging machines for powders and granules

Weighing and dosing systems

Palletizing equipment

Integrated packaging lines

PT Chronos has many machines for different needs. Their systems can pack small bags and big bags. This makes them good for lots of businesses.

Unique Features

PT Chronos makes machines that are fast and accurate. Their equipment uses load cells and digital controls. This helps each bag get the right amount inside. Dust collection systems keep the area clean and safe. Some machines can cap, seal, and label bags. The modular design lets companies add new parts later. PT Chronos helps businesses follow GMP and ISO rules.

Tip: PT Chronos machines help pack faster and keep areas clean.

Customer Feedback

Customers say PT Chronos machines work well and fill bags fast. Many people like how the machines keep work areas clean. The support team helps quickly and fixes problems. PT Chronos is trusted for being reliable and giving strong service.

Chemical Powder Packaging Machine Comparison

Features Table

The table below lists key features from top makers. You can check which machines match your needs.

Tip: Henll’s Fully Automatic Ton Bag Packaging Machine is special for its high accuracy and dust removal.

Pros & Cons

Here is a simple look at what each maker does well and not so well.

Henll

👍 Very accurate, strong build, easy to use, fast help

👍 Dust removal keeps the area clean

Shemesh Automation

👍 Reliable, custom choices, smart dosing

👎 Custom machines may cost more

Finopack

👍 Fills bags fast, simple controls

👎 Some models have fewer bag sizes

All-Fill

👍 Tough, easy to set up, smart controls

👎 Best for small and medium bags

Premier Tech

👍 Connects with other machines, dust control, custom options

👎 Complex systems may need training

Viking Masek

👍 Flexible design, touch screen controls

👎 Some models need extra space

PAYPER

👍 Smart weighing, good safety

👎 Semi-automatic models may need more workers

Webster Griffin

👍 Training, electronic weighing

👎 Focuses on big bags only

Concetti

👍 Automation, safety, easy to set up

👎 May need more money to buy

PT Chronos

👍 Modular design, dust collection

👎 Advanced features may cost more

Price Range

Each maker sells machines at different prices. The table below shows what buyers might pay.

Note: Prices change based on size, features, and automation. Henll gives good value for big bag packaging with advanced features.

Customer Ratings

Customer ratings help buyers see how well each machine works. Ratings show what users think about reliability, easy use, support, and happiness. Many companies share their thoughts online or in reports. The table below shows average ratings for the top brands. Ratings go from 1 to 5 stars, with 5 as the best.

Henll gets perfect scores in every part. Users say the Henll Fully Automatic Ton Bag Packaging Machine works great. They find the touch screen simple to use. The machine packs bags fast and right. Many customers like the dust removal system. It keeps the workspace clean. Henll’s support team answers quickly and fixes problems in one day. This helps companies keep working.

Customers often say Henll’s machines are strong and service is good. They say the machine saves time and cuts waste.

Shemesh Automation also gets high scores for reliability. Some users say their machines need more training. Finopack and All-Fill get good scores for easy use. Premier Tech does well in reliability and support. Viking Masek, PAYPER, Webster Griffin, Concetti, and PT Chronos all have solid ratings. Most users like the tough build and simple controls.

Many buyers want machines that work well every day. They want easy controls and quick help when problems come up. Henll’s machine gives these things. The company’s focus on quality and customer care builds trust.

Tip: When picking a packaging machine, look at ratings and reviews. High scores mean the machine works well and the company helps fast.

Customer ratings show what you can expect. Henll is the leader in satisfaction, making it a top pick for chemical powder packaging.

Choosing the Right Manufacturer

Assessing Needs

Each business needs different packaging. Some pack fine powders. Others pack granules or bulk items. First, list what you want to pack. Bag size, weight, and material are important. Some products need extra care. This stops moisture or contamination. Chemicals often need sealed bags for safety. Think about how many bags you fill daily. If you fill many bags, you need a fast machine. If your space is small, pick a compact machine.

Tip: Write down product details and how many bags you need each day before you look for machines.

Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG) fits many jobs. It works for powders and granules. The machine fills bags from 100 to 1000 kilograms. This is good for small and big batches.

Budget & Value

Price matters, but value is more important. Set your budget before you shop. Check what comes with the machine. Some machines cost less but break more often. Others cost more but last longer and work better. Compare prices, features, and support.

A table helps you see value:

Henll gives strong value. The machine uses carbon steel and stainless steel. It has a dust remover and accurate weighing. Fast customer support adds more value.

Note: Paying more can mean better quality and less time fixing.

Technical Specs

Technical specs show if a machine fits your job. Check the weighing method, sealing type, and speed. Some machines use electronic weighing for better accuracy. Others use manual scales. Sealing is important. Heat sealing keeps bags closed and safe. Speed matters for big orders. Some machines fill one bag every few minutes.

Henll’s machine uses electronic under-weighing. It fills each bag with high accuracy, usually within ±50 grams. The touch screen is easy to use. Dual-track heat sealing keeps bags safe from leaks. The machine fills one bag every eight minutes. It also has a dust remover to keep the area clean.

Match machine specs to your product and workflow. The right Chemical Powder Packaging Machine can make work safer and save time.

After-Sales Support

After-sales support helps companies keep machines working well. Good support means machines break less and work longer. Many manufacturers give different kinds of help after you buy. Some let you call for help. Others send workers to fix machines. Getting help fast saves time and money.

Henll is known for great after-sales support. They promise to answer any problem in 24 hours. This quick help stops long breaks in work. Henll’s team answers questions and fixes problems fast. They also teach workers how to use the machine. Training helps workers use the Henll Fully Automatic Ton Bag Packaging Machine (100-1000KG) the right way. The touch screen makes learning simple. Henll’s team helps set up the machine and gives tips for best use.

Other top brands also give support. Some have online guides and videos. Others check machines often to keep them working. The table below shows what support top brands give:

Tip: Fast and good support keeps machines running and saves money.

Henll’s quick help and training make it a top pick for strong support. The company cares about customers and builds trust for the future.

Certifications

Certifications show a company follows safety and quality rules. These certificates help buyers trust the machines they get. Common certifications are ISO, CE, and GMP. ISO means the company follows world rules for quality. CE shows the machine is safe in Europe. GMP is needed for food and chemical packing.

Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG) meets high quality rules. The machine uses strong carbon steel and stainless steel. Henll follows industry rules to make safe and strong machines. Their machines pass tests for being safe and accurate. This helps companies follow laws and industry rules.

Other top brands also have certifications. Some show their certificates on their websites. Buyers should ask to see certificates before buying. The table below lists common certifications and what they mean:

Note: Certified machines help companies follow rules and keep products safe.

Henll’s focus on quality and safety helps buyers feel safe. Their machines help companies follow rules and give safe products to customers.

Innovations & Trends

Automation Advances

Manufacturers keep making packaging machines better with new technology. Many companies use smart sensors and fast automation now. These upgrades help machines work quicker and more exactly. For example, detergent packaging machines with Doypack systems fill and seal bags fast. Sensors check each step so every bag has the right amount. Flexible packaging lets companies change products without stopping work. These changes help factories pack more bags each day. They also help keep product quality high.

Henll is a leader with its Fully Automatic Ton Bag Packaging Machine (100-1000KG). This machine uses electronic weighing and a touch screen for easy use. The dual-track heat sealing strip keeps bags closed tight. The dust removal device helps keep the workspace clean. Henll’s machine shows how automation makes packaging safer and better.

Tip: Automation helps companies save time and make fewer mistakes. Machines with smart controls can pack more bags and keep products safe.

Sustainability

Many companies want to help the environment. They look for machines that use less energy and make less waste. New packaging machines use strong materials that last longer. Some machines have dust removal systems to keep the air clean. Others use sealing methods that stop leaks and keep products fresh. These features help companies lower their impact on the planet.

Henll’s machine uses carbon steel and stainless steel. These materials last a long time and do not break easily. The dust remover keeps powder from spreading in the air. This helps workers stay healthy and keeps the factory clean. Companies using Henll’s machine can pack products safely and help the environment.

Note: Picking machines with energy-saving features and dust control helps companies reach green goals.

Customization

Factories need machines that fit their special needs. Some companies pack fine powders. Others pack big granules or bulk items. Modern machines give many choices for bag size, weight, and sealing type. Touch screens let workers change settings quickly. Some machines can switch between different products with little effort.

Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG) gives companies many options. It fills bags from 100 to 1000 kilograms. The touch screen makes it easy to set up for different jobs. The machine works for chemicals, building materials, grains, and new energy products. Customization helps companies pack products the way they want.

Tip: Machines with flexible settings help companies grow and meet new market needs.

Customer Experiences

Success Stories

Many companies made their packaging better with Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG). One chemical company needed to pack lots of powder fast. They got Henll’s machine and packed twice as quickly. The electronic weighing system helped them lose less product. Workers liked the touch screen because it was simple. The dust removal device kept their workspace clean. Another building materials company wanted safer packaging. They used Henll’s machine and saw fewer bags get damaged during shipping. The dual-track heat sealing strip kept their products safe from moisture and contamination.

Other companies also had good results. A grain producer started using Henll’s machine for bulk packaging. They had less waste and loaded bags faster. The strong frame and stainless steel platform helped them move heavy bags easily. Many users say Henll’s support team helps quickly and fixes problems fast.

Customers often say, “Henll’s machine makes our work easier and safer.”

Common Challenges

Companies have problems when packing chemical powders. Dust can get in the air and hurt people. Some machines do not seal bags well, so they leak and get contaminated. Weighing mistakes can make companies lose product or upset customers. Slow machines make it hard to keep up with orders.

Henll’s Fully Automatic Ton Bag Packaging Machine helps with these problems. The dust removal device stops powder from escaping. The electronic weighing system gives accurate results every time. The dual-track heat sealing strip closes bags tightly. These features help companies avoid common mistakes.

Lessons Learned

Companies learn important things when they use advanced packaging machines. They find that buying good equipment saves money later. Accurate weighing means less waste. Strong sealing keeps products safe. Fast support helps production keep going.

Many users say it is smart to train workers before starting. They think learning the touch screen makes work easier. Regular maintenance keeps the machine working well. Companies also learn that picking a trusted brand like Henll gives better results.

Tip: Companies should know what they need, train their workers, and choose machines with good support and safety features.

Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG) shows that the right machine can make work safer, faster, and better.

Picking the best chemical powder packaging machine is important for all businesses. The blog looked at top brands and explained why Henll is strong. Henll’s Fully Automatic Ton Bag Packaging Machine (100-1000KG) stands out. People should check which machine features fit their needs. Good support and tough design help companies do better work.

Check the comparison table for key details.

Follow the tips to help you choose.

Talk to manufacturers to get prices, see demos, or ask questions before you decide.

FAQ

What industries use Henll’s Fully Automatic Ton Bag Packaging Machine?

Henll’s machine is used in many industries. Chemical companies use it. Building materials companies use it too. Grain businesses also use this machine. New energy companies pack with it. It packs powders and granules safely. It works quickly for these jobs.

How accurate is the weighing system in Henll’s machine?

The electronic under-weighing system is very accurate. It fills each bag within ±50 grams. This helps companies lose less product. Accurate weighing saves money for businesses.

What is the bag size range for Henll’s packaging machine?

Henll’s machine packs bags from 100 to 1000 kilograms. This range fits many business needs. Small and large batches can be packed.

How does Henll’s machine keep the workspace clean?

The machine has a dust removal device. This device collects powder during packing. It keeps the area clean and safe for workers.

Is the machine easy for workers to operate?

Workers control the machine with a touch screen. The screen is simple and clear. Training helps workers learn to use it fast.

What materials make up Henll’s packaging machine?

Henll’s main frame is made of carbon steel. The platform panel uses 304 stainless steel. These materials make the machine strong and last long.

How fast can Henll’s machine pack bags?

Henll’s machine packs one bag every eight minutes. This speed helps companies work faster. It also saves on labor costs.

What after-sales support does Henll provide?

Henll gives quick customer support. The team answers problems within 24 hours. They help with setup and training for workers.