A pharmaceutical packaging machine gets medicines ready to send out. It also keeps them safe from germs and dirt. Companies use these machines to wash, fill, seal, and label medicines. There are different types of pharmaceutical packaging machines. Some are sterile washing machines, liquid filling machines, powder filling machines, sealing machines, labeling machines, cartoning machines, and case packers. Automation in pharmaceutical packaging helps make fewer mistakes. It also makes work faster and helps follow safety rules. Packaging is important because it keeps medicines safe, the same every time, and easy to find.

Sterile washing machines clean medicine containers.

Liquid and powder filling machines put the right amount in each package.

Sealing, labeling, and cartoning machines close and mark packages.

Case packers and full packaging lines get products ready to ship.

Key Takeaways

Pharmaceutical packaging machines keep medicines safe from germs and dirt when shipped. Different machines do special jobs like filling, sealing, and labeling to make packaging easier. Automation in packaging helps stop mistakes and makes things faster, so companies save time and money. Blister packaging machines let people see the medicine, so it is easy to know what it is. Bottle filling machines give the right amount of medicine, so there is no waste and every product is the same. Labeling machines are important for rules and show key facts like expiration dates and batch numbers. Sealing machines make strong covers that keep medicines safe from germs and keep them good. Picking the right packaging machine is important for working well, staying safe, and following the rules.

Types of Pharmaceutical Packaging Machines

Blister Packaging Machines

Blister packaging machines are important in medicine packaging. These machines make sealed pouches for tablets and capsules. They use heat and pressure to shape a plastic pouch. Each pouch gets filled with a tablet or capsule. The machine then seals the pouch with aluminum foil. This keeps medicine safe from water, dust, and germs.

Blister packaging machines give clear and neat packaging. The see-through pouch helps people check the medicine inside. This makes it easier to identify and stay safe. Many machines use a turntable platform. This lets them make lots of pouches at once. It helps work go faster and saves time.

Here is a table that shows what blister packaging machines do:

Big and medium-sized companies also use blister packaging machines. These machines use control technology for machine, electricity, light, and gas. They follow strict rules for the industry. They can make PVC blisters, fill them, and seal with aluminum foil. These machines are good for packing tablets and capsules in special pouches.

Bottle Filling Machines

Bottle filling machines help pack liquid and solid medicines in bottles. These machines put the right amount in each bottle. They work for both liquid medicine and solid tablets. Automatic systems help make sure each bottle has the correct dose. This stops mistakes and keeps bottles the same.

Bottle filling machines have many good points:

Automatic systems fill bottles with the right amount.

These machines help save money by using less labor and wasting less product.

They keep the workspace clean by stopping spills.

Dropper bottle fillers give the exact amount of liquid needed.

They help stop spills and waste, keeping things tidy.

These machines work fast and can fill many bottles quickly.

Bottle filling machines work with many kinds of bottles. They can fill bottles of different shapes and sizes. This makes them useful for many medicines. These machines help companies follow safety rules and keep medicine safe for people.

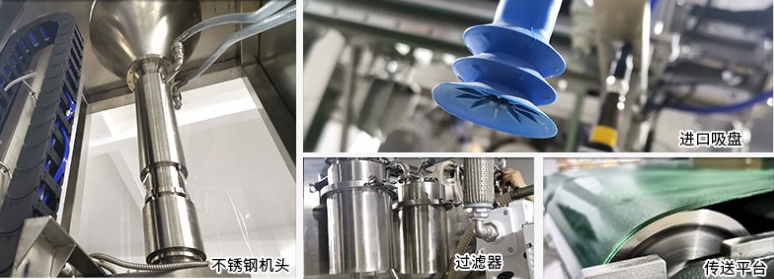

Liquid Filling Machines

Liquid filling machines pack liquid medicines. They fill pouches, bottles, or vials with the right amount. These machines use smart technology to fix problems like sealing, dosing, and wasting materials.

Here is a table that shows how liquid filling machines solve problems:

Liquid filling machines have important safety features:

They can fill many shapes and sizes of containers.

Speed settings help workers match how fast they need to work.

Easy cleaning and care help keep things safe and clean.

Vacuum suction and dust removal keep the workspace tidy.

Liquid filling machines help companies pack liquid medicines quickly. They use recyclable materials and smart automation. This helps save money and protect the environment. These machines are very important for making good medicine packaging.

Strip Packing Machines

Strip packing machines are very important in making medicine packages. These machines wrap products in a long strip of material. They seal and cut the strip into small pouches. Each pouch keeps medicine safe from air and water. It also protects medicine from light. Strip packing machines work for many medicine types. They can pack tablets, capsules, powders, and granules. They also handle solid tablets and semi-liquids like gel capsules. Some machines can even pack liquid products.

Tablets

Capsules

Powders

Granules

Solid tablets

Semi-liquids (liquid soft-gel/gel capsule)

Liquid products

Strip packing machines use special features to keep medicine safe. Many machines add desiccants to control moisture inside each pouch. The table below shows how these machines help protect medicine:

Strip packing machines help companies follow safety rules. They keep medicine fresh until people use it. These machines also work fast and help make lots of packages quickly.

Cartoning Machines

Cartoning machines make boxes for medicine. They start with flat cartons and turn them into boxes. The machine puts products like blister packs or bottles inside each box. It seals the box with glue, tape, or folds.

Carton forming: The machine makes boxes from flat cartons.

Product loading: It puts products in the boxes by hand or automatically.

Carton sealing: The machine closes and secures the boxes.

Cartoning machines protect medicine during shipping and storage. They make packaging faster and more dependable. The table below shows how these machines help companies:

Cartoning machines are needed for packing lots of medicine. They help keep quality high and meet market needs.

Labeling Machines

Labeling machines put labels on medicine packages. These machines make sure every bottle or pouch has the right information. Good labeling helps keep people safe and makes tracking easy. It also helps companies follow laws.

Labeling machines use printers to make labels with barcodes and dates. Sensors check if labels are in the right spot. Machines can work with other packaging machines to keep things running smoothly.

Label printers make labels with all the needed details.

Sensors check for labels and product position to stop mistakes.

Working with other machines helps track products and keep records.

Some labeling machines use vision systems. These systems check each label for quality. They remove any labels that are not good enough. This helps companies follow strict rules and keep patients safe. Labeling machines are important for making sure medicine packages are correct and legal.

Sealing Machines

Sealing machines are very important in packaging medicine. They close pouches and blister packs to keep medicine safe. These machines use heat, pressure, or induction to make strong seals. A strong seal stops air, water, and germs from getting inside. This helps keep medicine fresh and protected.

There are different sealing machines for different jobs. Each type has special features for certain packaging needs.

Some other sealing machines are used often:

Back Side Sealing Tipping Bucket Automatic Packing Machine SW-2030C: Good for packing small things like candies and herbal medicines.

Plastic Sealing Machine: Makes bags and pouches airtight.

FP800-S300 Desktop Manual Type Tray/PP Box Sealing Machine: Seals plastic boxes and trays for medicine, cosmetics, and food.

Induction sealing machines use special energy to seal containers with foil. This makes packages hard to open and helps stop leaks.

Sealing machines have many good points:

Sealing machines help keep medicine safe by:

Stopping leaks and keeping germs out

Sealing blister packs, sachets, and gauze

Keeping things clean and fresh longer

Meeting safety rules in hospitals and pharmacies

These machines are needed for any medicine packaging job. They help make sure packages have strong and safe seals.

Powder Packaging Machines

Powder packaging machines fill and seal medicine powders. They measure and put the right amount of powder in each pouch. These machines keep the powder clean and safe from dirt. Powder filling machines are used for things like antibiotics, vitamins, and supplements.

Powder packaging machines have many advantages:

Many powder packaging machines do filling, sealing, and labeling by themselves. They help save product and lower the chance of mixing powders. These machines also help companies spend less on workers and follow strict rules.

Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine

Henll makes advanced packaging machines. The Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine is special in medicine packaging. This machine fills and seals pouches with great accuracy. It works with many kinds of medicine powders.

Here are some key features of the Henll machine:

The Henll machine can work with different bag sizes and types. Workers can change products fast. The touchscreen makes it easy to check and change settings. This machine helps companies work faster, save money, and keep products high quality.

Powder packaging machines, like the Henll one, are very important in medicine packaging. They make sure each pouch has the right amount of powder and stays safe until someone uses it.

Tertiary Packaging Machines

Tertiary packaging machines get medicine ready for shipping and storage. They group small packages like pouches and bottles into big boxes or crates. This keeps products safe when moving and makes them easier to handle.

Tertiary packaging machines include case packers, palletizers, and stretch wrappers. They stack and hold products on pallets. These machines help move lots of medicine safely and quickly.

Here are some good things about tertiary packaging machines:

Keep products safe from damage when shipping

Group packages so they are easy to move

Help store and transport medicine better

Make sure shipping rules are followed

Tertiary packaging machines work with cartoning, sealing, and labeling machines. Together, they make a full packaging line for medicine. This helps medicines arrive safe and in good shape.

Pharmaceutical Packaging Process

The pharmaceutical packaging process has three main steps. Each step uses special machines to keep medicine safe and easy to use.

Primary Packaging

Primary packaging is the first layer around the medicine. It keeps medicine safe from water, air, and germs. This step uses blister packaging machines, filling machines, and powder packaging machines. Blister packaging machines put tablets and capsules in small pockets. Filling machines measure and fill bottles with liquid or solid medicine. Powder packaging machines, like the Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine, fill pouches with the right amount of powder. The Henll machine works fast and is very accurate. It helps companies keep medicine clean and the same every time.

Tip: Primary packaging keeps medicine fresh and safe until you use it.

Secondary Packaging

Secondary packaging adds another layer around the medicine. It puts groups of primary packages together for branding and easy handling. Cartoning machines fold and seal boxes around blister packs, bottles, or pouches. Labeling machines put important information on each box, like batch numbers and expiration dates. Sealing machines close boxes tightly. Secondary packaging helps companies organize medicine for shipping and storage. It also makes medicine look neat and easy to find.

Cartoning machines put blister packs and bottles together.

Labeling machines add tracking information.

Sealing machines keep boxes closed tight.

Tertiary Packaging

Tertiary packaging is the last layer. It gets medicine ready for shipping and storage in big amounts. Tertiary packaging machines, like case packers and palletizers, stack boxes and put them on pallets. Stretch wrappers wrap the boxes to keep them safe during shipping. This step protects lots of medicine during long trips. Tertiary packaging machines work with secondary packaging machines to make a full packaging line.

Each step uses different machines to keep medicine safe, neat, and ready to send out. Companies pick the best machine for each step to follow safety rules and work better.

Key Features of Packaging Machines

Automation and Efficiency

Automation is very important in medicine packaging today. Machines with automation do jobs like filling, sealing, and labeling fast and well. These machines mean people do not have to do as much work by hand. This helps companies spend less money on workers. Automated machines also help keep things clean and safe. They make sure every package is made the right way.

Medicine packaging uses automation to keep up with lots of orders. Machines work fast and do the same thing every time. This helps the whole line run without problems. Automation helps companies follow safety rules, which keeps people safe. When companies use automated machines, they save money and make more medicine in less time.

Tip: Automated machines help companies follow safety rules and save money.

Precision and Consistency

Precision and consistency are very important in medicine packaging. Machines measure and fill each container with the right amount. This stops mistakes and keeps medicine safe for people. When packages are always the same, it helps companies follow safety rules and keep quality high.

Machines use sensors and controls to check every step. They make sure every bottle, pouch, or blister pack is filled right and looks the same. When packaging is always the same, it keeps medicine safe from dirt and damage. It also helps if a company needs to find or recall medicine.

Adaptability and Versatility

Adaptability and versatility let machines work with many kinds of medicine. Machines can change to fit different sizes, shapes, and materials fast. This helps companies keep up with new products and what people want.

Henll makes the Full-Automatic Powder Sewing Bag Filling And Packaging Machine. This machine works with many powders and bag types. It is a good choice for making medicine. Workers can use a touchscreen to change settings quickly. This means less waiting and more work done.

Using eco-friendly packaging is getting more important. Versatile machines can use green materials and new designs. This helps companies care for the planet and reach their green goals.

Note: Versatile machines help companies stay ahead and use eco-friendly packaging.

Compliance and Safety

Pharmaceutical packaging machines must follow strict rules to keep medicine safe. These rules help protect people who take the medicine. They also make sure every package is made the right way. Companies like Henll design machines to meet these important rules.

Regulatory groups make the standards for these machines. These standards say how machines should work and keep workers safe. They also help keep medicine clean. The table below lists some main groups and their standards:

ISO 9001 helps companies keep their work the same and high quality. ISO 22000 is about food safety, but it also helps with medicine. ANSI gives advice on how to build and use machines. The FDA checks if packaging materials are safe for medicine. OSHA makes sure workers are safe when using machines.

Packaging machines must keep medicine clean from germs and dirt. They use sealed systems and special filters to stop contamination. Machines like the Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine use smart controls. These controls help keep powders clean and measured right. This helps companies follow safety rules and keep people safe.

Safety features on machines protect both medicine and workers. Emergency stop buttons, safety guards, and alarms help stop accidents. Machines have sensors that check for problems and stop if something is wrong. These features help lower the chance of injury and keep the area safe.

Note: Following safety and compliance rules is not just about laws. It also helps people trust the company and keeps patients healthy.

Companies that use safe packaging machines show they care about quality. They can track every package back to where it started. This helps if there is a recall. Good records and clear labels make it easy to follow products through the supply chain.

How Pharmaceutical Packaging Machines Ensure Safety and Compliance

Product Integrity

Pharmaceutical packaging machines help keep medicine safe. They protect products from water, light, and air. Strong seals stop leaks and keep medicine fresh. Accurate filling makes sure each package has the right amount. Sensors check every step of the process. Automated controls help packages stay closed until people use them.

Henll makes machines that focus on keeping products safe. The Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine uses smart technology. It fills each bag with the right amount of powder. The machine seals bags tightly so nothing leaks out. Operators use a touchscreen to watch the process. This helps every package stay the same and safe.

Tip: Machines that fill and seal packages well help companies give safe medicine to patients.

Regulatory Standards

Pharmaceutical packaging must follow strict rules. Groups like the FDA and ISO make these rules. Packaging machines help companies meet these standards. Machines record data for every batch. They print labels with important details like expiration dates and batch numbers.

Many machines have safety features. Emergency stop buttons and alarms help protect workers. Machines use materials that are safe for medicine. Henll builds machines that meet global standards. The company tests its machines to make sure they work safely.

Companies trust machines that follow these rules. They know their products will pass checks and reach people safely.

Reducing Contamination Risks

Contamination can hurt medicine. Packaging machines help lower this risk by using closed systems. Automated filling and sealing keep powders and liquids away from germs and dust. Machines with HEPA filters clean the air near the product. Operators do not touch the product while it is packed.

Henll’s machines use smart controls to stop contamination. The Full-Automatic Powder Sewing Bag Filling And Packaging Machine keeps powders inside sealed chambers. Workers can change products quickly without opening the system. This helps keep the workspace clean.

Closed systems keep germs away from products.

Automated controls mean less human contact.

Filters and sensors help keep the air clean.

Note: Clean packaging lines help companies give safe medicine to patients.

Choosing the Right Pharmaceutical Packaging Machine

Picking the best pharmaceutical packaging machine helps companies keep products safe. It also helps them follow important rules. Each company should think about what it needs before buying a machine. The right machine makes work faster, saves money, and keeps medicine safe.

Assessing Product Requirements

Companies first look at what they need to pack. Tablets, powders, liquids, and capsules need different machines. Some products need extra care to stop contamination. Others need exact filling so each dose is right. For example, powder products need machines that fill bags with the right amount and seal them well. Henll has the Full-Automatic Powder Sewing Bag Filling And Packaging Machine. This machine fills and seals bags very accurately. It also keeps the powder clean.

Tip: Companies should write down the size, shape, and type of product before picking a machine.

Evaluating Machine Capabilities

After knowing the product, companies check what each machine can do. They see if the machine works with different sizes and shapes. Easy controls, like touchscreens, help workers use the machine. Machines that are very accurate help stop waste and keep products the same. The table below shows what to think about:

Henll is known for making good pharmaceutical packaging machines. Their advanced machines, like the Full-Automatic Powder Sewing Bag Filling And Packaging Machine, have easy controls and quick changes. These features help companies work faster and make fewer mistakes.

Considering Future Scalability

Companies should think about growing in the future. A machine that works now might not be enough later. Machines with flexible settings and quick changes help companies add new products easily. Scalable machines let companies make more products as they grow. Buying adaptable machines saves money over time.

Note: Picking a machine that can grow with the company helps avoid spending more money later.

Henll makes machines that can change as companies grow. Their machines switch between bag sizes and product types quickly. This makes them a smart choice for companies that want to make more pharmaceutical products in the future.

Pharmaceutical packaging machines keep medicines safe and ready to ship. Each machine does a different job, like filling, sealing, or labeling. Picking the right machine helps keep medicine safe and work fast. It also helps companies follow important rules. Henll makes smart machines that use automation to help workers. Packaging is getting more important as companies want good and reliable results.

FAQ

What is a pharmaceutical packaging machine?

A pharmaceutical packaging machine gets medicine ready to sell. It fills, seals, and labels each product. These machines help keep medicine safe from dirt and germs.

Why do companies use automated packaging machines?

Automated machines work faster than people. They make fewer mistakes and save money. Automation helps keep the packaging process clean and the same every time.

How does the Henll Full-Automatic Powder Sewing Bag Filling And Packaging Machine help pharmaceutical companies?

Henll’s machine fills and seals powder bags very well. It works with many bag sizes and types. The touchscreen makes it easy and quick to use.

What types of medicines need special packaging machines?

Tablets, capsules, powders, and liquids all need different machines. Some products, like powders, need machines that stop contamination and measure the right amount.

How do packaging machines keep medicines safe?

Packaging machines use strong seals and closed systems. These features protect medicine from air, water, and germs. Sensors and filters help keep everything clean.

What is the difference between primary, secondary, and tertiary packaging?

Primary packaging touches the medicine itself. Secondary packaging groups primary packages for storage or sale. Tertiary packaging gets big groups ready for shipping.

Can one machine handle different products?

Many new machines, like Henll’s, can change for different sizes and types. This helps companies package many kinds of medicine.

Why is labeling important in pharmaceutical packaging?

Labeling gives important facts, like batch numbers and expiration dates. It helps track products and makes sure patients get the right medicine.