Which snack packaging machine is best for your snack? Your choice changes how fresh, good, and cheap your snack is. Snack packaging must fit things like how easy it breaks, how wet it is, and its size. For example, vacuum-sealing or nitrogen-flush machines help snacks without preservatives stay fresh longer. Packaging machines that work with multilayer films keep out air and water. The table below shows how picking the right machine for your snack changes how long it lasts and how much it costs:

Aspect | Impact on Snack Packaging |

|---|---|

Shelf Life | Vacuum and MAP machines keep snacks fresh longer, especially if they have no preservatives. |

Cost Efficiency | Big packages cost less for each pound; small bags cost more. |

Packaging Material | Machines need to use barrier films for better snack quality and safety. |

Think about things like how much you make, your packaging goals, and your budget. The right snack packaging machines help you give people good snacks that stay fresh and save money.

Key Takeaways

Pick packaging machines that fit your snack’s type and texture. This helps keep snacks fresh and safe. Use machines with vacuum sealing or nitrogen flushing features. These features help snacks last longer. Choose packaging materials that stop air, moisture, and light. This protects the quality of your snacks. Match the machine’s speed and automation to how much you make and your budget. This gives you better results. Good packaging machines save time and cut down on waste. They also help your snack business get bigger.

Snack Types and Packaging Needs

Chips and Crisps

You need to protect chips and crisps from breaking and going stale. These snack items are fragile and lose their crunch if exposed to air or moisture. Snack food packaging for chips uses multi-layer bags made from strong material like BOPP and LDPE. This packaging keeps out moisture, oil, and light. You must also follow strict rules for labeling and food safety. Machines like multi-head weighers help you fill each bag with the right amount of snack. Good packaging design also helps your snack stand out on the shelf.

Tip: Choose packaging that balances cost, strength, and freshness for your chips and crisps.

Nuts and Seeds

Nuts and seeds have high oil and moisture content. If you do not use the right snack food packaging, these snack items can spoil or grow mold. You should dry nuts and seeds to safe moisture levels before packaging. Use material with strong barriers, such as polyvinyl chloride or metal laminates, to keep out air and moisture. Modified atmosphere packaging with nitrogen can help keep your snack fresh and prevent oxidation. The right packaging machine must handle the oiliness and size of these snack items.

Baked Goods

Baked goods like cookies and pastries need snack food packaging that keeps them soft and fresh. Poly bags and modified atmosphere packaging help keep out air and hold in moisture. For short-term storage, you can use paper or clamshell containers. For longer shelf life, use airtight packaging and heat sealing. You should also use rigid containers or cushioning to protect delicate snack items from crushing during shipping.

Use clear labels like "Fragile" or "Perishable" to help handlers care for your snack.

Dried Fruits

Dried fruits absorb moisture easily and can clump together. Snack food packaging for these snack items must use material with excellent moisture barriers, such as foil pouches or Mylar bags. Machines with auger fillers and airtight sealing keep out air and water. Nitrogen flushing or oxygen absorbers inside the packaging help prevent spoilage and keep your snack fresh. Resealable pouches or jars let you keep the snack fresh after opening.

Snack Bars

Snack bars need strong snack food packaging to keep their shape and stay fresh. Use durable material that protects against crushing and keeps out air. Tamper-evident seals and clear branding help your snack stand out and stay safe. Packaging machines must wrap and seal each snack bar tightly. Nitrogen flushing can help keep the snack fresh by reducing oxidation.

Choose packaging that fits your snack bar’s size and supports easy stacking for shipping.

Popcorn and Puffed Snacks

Popcorn and puffed snacks break easily and need gentle handling. Snack food packaging for these snack items often uses stand-up pouches, tubes, or jars made from lightweight but strong material. Machines must fill and seal the packaging without crushing the snack. Resealable bags help keep the snack fresh after opening. Packaging must also keep out moisture and air to protect the snack’s crunch.

Confectionery

Confectionery snacks like candies can melt or stick together. You need snack food packaging that keeps out heat and moisture. Use multilayer films with a sealant inside and a strong outer layer. Packaging machines with non-stick surfaces and precise weighing help prevent sticking and damage. Keeping the packaging area cool and dry also helps protect your snack items.

Note: New packaging material options, like monolayer films, help you protect your snack and support recycling.

Different Types of Snack Packaging Machines

Multihead Weigher VFFS Machines

Multihead weigher VFFS machines weigh snacks very accurately. They use many small scales to measure each bag. The VFFS part makes bags from a film roll. It fills and seals them in one step. You can pack chips, popcorn, nuts, candies, and pretzels. These machines are good for making lots of snacks fast. Every bag has the same weight. They help save money on work and materials. You can pick pillow bags or gusseted bags. This machine is great for snacks sold by weight.

This equipment can pack hundreds of bags every minute.

It works for both fragile and chunky snacks.

Multihead Weigher Pouch Packing Machines

Multihead weigher pouch packing machines weigh and fill snacks quickly. They can change pouch sizes and styles fast. You can use resealable or fancy pouches. These machines are best for granola, trail mix, and candies. They are fast and flexible. This makes them a good choice for snacks that need quick changes.

Feature | Multihead Weigher Pouch Packing Machines | Jar Filling Machines |

|---|---|---|

Packaging Speed | High speed: 50 to 120 packs per minute | Not specified |

Packaging Flexibility | High flexibility: supports various pouch sizes, styles, resealable options, and quick changeovers | Not detailed |

Packaging Styles | Pouches with zip locks, premium presentation | Generally used for different packaging needs |

Production Efficiency | Enhanced by integration with VFFS, multihead weighers, and automation | No specific details |

Multihead Weigher Jar Filling Machines

Multihead weigher jar filling machines fill jars fast and accurately. They are good for snacks that need hard containers. You can use them for nuts, seeds, or dried fruits. These machines protect snacks from getting crushed. They are not as fast or flexible as pouch machines. But they give strong packaging for fancy snacks.

Flow Packaging Machines

Flow packaging machines wrap snacks in a long film. They seal each snack tightly. These machines are best for single snacks like bars, cookies, or candies. They work fast and make airtight, safe packages. Flow machines keep snacks fresh and safe. You can use bright films for your brand. They make pillow or fin-sealed bags.

These machines can pack snacks of many shapes and sizes.

You save money on materials and work with this equipment.

Premade Pouch Packing Machines

Premade pouch packing machines fill and seal ready pouches. You can use stand-up or zipper pouches. These machines are good for chips, puffed snacks, and nuts. They work automatically and make every package look the same. You can choose from many pouch types to make your snack look good and easy to use.

Snack Type / Pouch Type | Features & Advantages | Why Suited for Premade Pouch Packing Machines |

|---|---|---|

Stand-up Pouches | Bottom support structure allows pouch to stand upright; excellent shelf presentation; consumer convenience | Ideal for snack foods like chips and puffed snacks; enhances shelf appeal and ease of handling |

Zipper Pouches | Re-sealable zipper mechanism; allows multiple openings and closings; extends freshness and shelf life | Suitable for snacks consumed incrementally; maintains product freshness and flavor; improves consumer convenience |

Snack Foods (chips, puffed snacks, nuts) | Fragile or irregular shapes; require precise filling and sealing | Machines provide precision filling and sealing, preserving product quality and presentation; compatible with premium pouch types |

Tray Sealing Machines

Tray sealing machines seal snacks in trays with tight film. They are good for soft or fancy snacks. Tray sealing keeps snacks fresh by taking out air and blocking germs. You can use clear trays to show your snacks. These machines let you pick tray sizes for different snacks. Some use gas to keep snacks fresh longer.

Tray sealing machines help stop food from spoiling.

They make snacks safer and last longer.

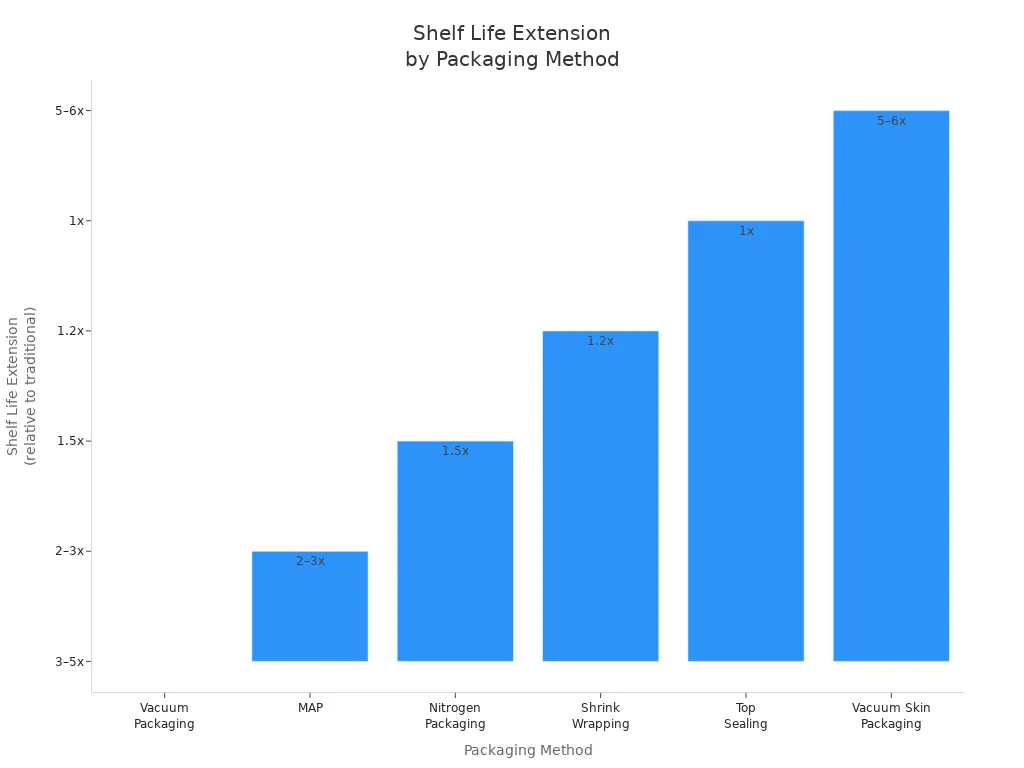

Vacuum Packaging Machines

Vacuum packaging machines suck out all the air before sealing. This keeps snacks fresh much longer than other machines. You can use vacuum packaging for snacks that spoil fast or need to stay crisp. These machines are good for nuts, dried fruits, and some baked goods. Vacuum packaging stops oxidation, keeps out water, and saves flavor.

Vacuum packaging machines make small packages and keep snacks fresh longer than shrink wrap or top sealing.

Matching Snack Packaging Machines to Snack Types

Fragile Snacks

Fragile snacks like chips and crackers break easily. You need to keep them safe during packaging. The right machine helps your snacks stay whole and look good. Think about the snack’s size, shape, and weight before picking a machine. Some machines use gentle stacking to stop sudden drops. This keeps your snacks from breaking. Robots can pick up snacks softly and put them in bags. This lowers the chance of damage. Special screens help you change settings without mistakes. Slow machines work best for fragile snacks. They move gently and do not shake the snacks. Good designs let you control the machine and keep snacks safe.

Tip: Match the machine’s speed and handling to how fragile your snack is. This helps your snacks look and taste their best.

Check your snack’s features before picking a machine.

Use gentle machines and robots for fragile snacks.

Pick packaging that cushions and protects your snack.

Free-Flowing Snacks

Free-flowing snacks like nuts and candies move easily in machines. You need a fast machine that keeps snacks fresh. Vertical form-fill-seal stick pack machines work well for these snacks. They are quick and accurate. You can change settings for different snack sizes and bags. These machines seal bags tight to keep air out. This helps snacks stay fresh. They work with many types of packaging, even eco-friendly ones.

Feature | Description |

|---|---|

Machines pack snacks fast and help you make more. | |

Reliability | Strong machines keep working without many problems. |

Advanced Sealing Tech | Tight seals keep snacks fresh and safe. |

Compatibility | Machines work with many packaging materials. |

Customization | You can change bag sizes and styles for your snack. |

Regulatory Compliance | Machines follow food safety rules to keep snacks safe. |

After-Sales Support | Training and repairs help your machine work well. |

You can use cup dosers or auger fillers for different snacks. Servo controls and touchscreens help you run the machine exactly. Extra features like gas flush and check weighers keep snacks fresh and high quality.

Sticky or Moist Snacks

Sticky or moist snacks like gummies and dried fruit need special care. You do not want them to stick together or spoil. Automatic zipper pouch machines with gentle filling work well for these snacks. These machines use vacuums to keep pouch openings clean. They seal bags tight so no air or germs get in. Nitrogen flushing takes out oxygen and keeps snacks fresh longer.

Pick packaging that blocks moisture to keep snacks fresh.

Use grease-proof layers like polyester or polypropylene inside the bag.

Cooling devices press and cool bags after sealing to keep snacks in shape.

Machines work with many pouch types, like zipper pouches, to keep snacks fresh after opening.

Note: Always use packaging that blocks gas and light for sticky or moist snacks. This keeps flavors strong and snacks fresh longer.

Mixed or Multi-Component Snacks

Mixed snacks like trail mix need every part to be safe and even. You want each bag to have the right mix and keep snacks whole. Accurate weighing systems help you put the right amount in each bag. Smooth transfer systems move snacks gently and keep them safe. Special feeding systems protect fragile or odd-shaped snacks.

Use servo motors for strong bags and tight seals.

Use two VFFS machines and one control for flexible packing.

Multi-pack systems use air or belts to move snacks evenly.

Reject systems take out bad snacks to keep quality high.

Blending systems mix snacks well for a perfect blend.

Tip: Gentle handling and good weighing help you make mixed snacks that taste great and stay fresh.

Key Factors for Choosing a Snack Packaging Machine

Snack Characteristics

When picking snack food packaging equipment, look at your snack’s traits. Every snack is different. Some snacks break easily, some are oily, sticky, or powdery. These things change how a packaging machine works with your snack. If your snack is fragile, use gentle machines. Sticky snacks need machines that stop clogging. Oily snacks need equipment that stays clean. Always match the machine to your snack’s texture and shape. This keeps your snack good and stops waste.

Fragile, oily, sticky, and powdery snacks need special care.

The right equipment keeps snacks safe and fresh.

Packaging Format

Packaging format changes how long your snack lasts and how it looks. You can use pillow bags, stand-up pouches, jars, or wraps. Each type works best with certain machines. Vertical form-fill-seal machines make pillow bags fast. Flow wrappers are good for bars and cookies. The packaging material must block air, water, and light. Good seals keep snacks safe and fresh. Test new packaging to make sure it works well. Testing helps you avoid problems with snack quality.

Factor | Impact on Machine Compatibility and Shelf Life |

|---|---|

Barrier materials keep snacks safe from air, water, and sunlight. | |

Sealing Techniques | Strong seals stop leaks and protect snacks. |

Packaging Machinery | Machines must work with your packaging type and stay fast. |

Product Format & Filling | Flexible machines help pack many snack types and keep them good. |

Production Volume

Production volume tells you which machine fits your needs. If you make over 100 bags each minute, use automated machines. These help you make more snacks and save money. If you make fewer snacks, semi-automatic machines may be better. Fast machines can pack up to 300 snacks each minute. You can start small and get bigger machines as you grow.

Tip: Pick a machine that matches how many snacks you make for better results.

Automation Level

Automation in packaging machines saves time and money. Automated machines fill, seal, and label snacks with little help. Robots and smart systems make fewer mistakes and work faster. You get more snacks and spend less on workers. Automation helps you grow your snack business. Always check if full automation is worth the cost.

Automated equipment makes snacks better and more even.

You can make more snacks without hiring more people.

Budget

Your budget decides which machine you can buy. Prices go from $5,000 for simple machines to over $250,000 for advanced ones. The packaging material, machine design, and automation level change the price. Custom features and fast machines cost more. Think about safety, shelf life, and snack quality when planning your budget. Pick equipment that fits your needs now and later.

Machine Type | Best For | |

|---|---|---|

Semi-Automatic Premade Pouch Filling | $5,000 – $15,000 | Startups, small snack makers, and labs. |

Automatic Premade Pouch Machines | $25,000 – $80,000+ | Small to medium snack businesses that need speed. |

Vertical Form-Fill-Seal (VFFS) | $30,000 – $120,000+ | Big snack makers. |

Horizontal Form-Fill-Seal (HFFS) | $80,000 – $250,000+ | Fancy snack packaging. |

Space and Material Compatibility

Space and material compatibility are important to think about. If your space is small, pick vertical machines. These save room and help you work better. Your equipment must work with your packaging material, like pouches or jars. The right machine keeps snacks safe and fresh. Easy cleaning and care help with food safety and less downtime.

Note: Make sure your machine fits your space and works with your packaging material.

How Snack Packaging Machines Work

Basic Operation Steps

Snack packaging machines follow simple steps to keep snacks safe. First, the machine makes a bag or uses a pouch. Next, it fills the bag with the right amount of snack. Then, it seals the bag to keep out air and water. Some machines print dates or codes on the bags. After that, the machine checks if the bag is sealed well and has the right weight. Last, the machine moves the finished bags to a conveyor for shipping. These steps help every snack bag look and taste the same.

Efficiency and Labor Savings

Snack packaging machines save time and money for snack makers. They work fast and only need one or two people to run them. You do not need a big team to keep things moving. Good machines do not break down often, so you can keep working. If you take care of the machines, they last longer and work better. Using these machines helps you make more snacks and pay less for workers. The machines also fill and seal each bag the same way every time, so your snacks are always good.

Tip: Using automated machines lets you spend more time growing your business and less time fixing problems.

Shelf Life and Freshness

Snack packaging machines help keep snacks fresh for a long time. They protect snacks from air, water, and light. You can pick different packaging materials like plastic, glass, or metal. Each material keeps snacks safe in its own way. Plastic keeps out water and air. Composite materials block air and light. Glass keeps out air and blocks light. Metal seals in freshness and keeps snacks safe. You can also use special ways like vacuum packaging to make snacks last longer. These methods help snacks stay fresh and taste good.

Packaging Material | Barrier Properties and Benefits | Impact on Snack Shelf Life and Freshness |

|---|---|---|

Plastic Film (PE, PP, PET) | Blocks moisture and oxygen | Prevents spoilage and keeps snacks fresh |

Composite Material | Stops air and light | Maintains extended shelf life |

Glass | Airtight and blocks light | Protects product quality |

Metal | Seals in freshness | Keeps snacks like nuts and popcorn safe |

Vacuum packaging and modified atmosphere packaging help snacks last even longer and stay high quality.

Branding and Product Appeal

Snack packaging machines help make your snacks look great in stores. You can use clear windows, bright colors, and cool shapes. Machines let you add zippers, seals, or bags you can heat in the microwave. These features make snacks easier and more fun to use. You can also use eco-friendly materials to help the planet. Picking the right machine helps your brand stand out and makes people want to buy your snacks. Most shoppers notice how snacks look, so good packaging helps you sell more.

Snack Packaging Machine Selection Checklist

Snack Type vs. Machine Type Table

Picking the best packaging machine depends on your snack’s traits. Use this table to match your snack with the right machine. This helps snacks stay fresh, safe, and look good.

Snack Type | Best Machine Type | Key Packaging Features |

|---|---|---|

Chips & Crisps | Multihead Weigher VFFS, Premade Pouch | Gentle handling, nitrogen flush, strong seals |

Nuts & Seeds | Multihead Weigher Jar Filling, VFFS | Airtight jars, vacuum sealing, oil-resistant films |

Baked Goods | Tray Sealing, Flow Packaging | Soft handling, moisture barrier, clear trays |

Dried Fruits | Vacuum Packaging, Premade Pouch | Moisture barrier, resealable pouches, oxygen absorbers |

Snack Bars | Flow Packaging, Horizontal FFS | Tight wrap, tamper-evident seals, branding options |

Popcorn & Puffed | Multihead Weigher VFFS, Premade Pouch | Cushioning, resealable bags, light barrier |

Confectionery | Flow Packaging, Tray Sealing | Non-stick films, temperature control, portion packs |

Tip: Make sure your machine can handle snacks of different sizes or shapes. This helps you add new snacks later.

Quick Buyer Checklist

Check these points before you buy a snack packaging machine. This list helps you pick the best one for your business.

1. Know your snack type (solid, sticky, powder, or mixed). 2. See if the machine works with your packaging material (plastic, foil, paper, or eco-friendly). 3. Match the machine speed to how many snacks you make (bags per minute or packs per hour). 4. Choose how much automation you want for filling, sealing, and labeling. 5. Make sure the machine is simple to clean and care for, especially if your snacks have allergens. 6. Check if the machine can link with other tools like labelers or metal detectors. 7. Make sure the machine follows food safety rules (like CE, FDA, or ISO).

Think about how strong the machine is and if you can upgrade it.

Look for features like nitrogen flushing or vacuum sealing to keep snacks fresh.

Plan your workspace so the machine fits and works well.

Remember: The right machine helps you save time, keeps snacks fresh, and helps your business grow.

Choosing the right snack packaging machine helps you protect your snack and keep its quality high. You need to think about your snack type, how many snacks you make, and your packaging goals. The right machine lets you save money and grow your snack business. Use the checklist and table to match your snack with the best machine. If you want the best results, talk to suppliers who know about snack packaging. Your snack deserves the best care from start to finish.

FAQ

What is the best packaging machine for small snack businesses?

You should start with a semi-automatic premade pouch filling machine. It costs less and fits small spaces. You can upgrade later as your business grows.

How do I keep my snacks fresh for a long time?

Use packaging with strong barriers like foil or multilayer film. Machines with vacuum or nitrogen flush features help keep air and moisture out. This keeps your snacks crisp and tasty.

Can one machine pack different types of snacks?

Many modern machines let you change settings for different snacks. You can adjust the filling, sealing, and bag size. Always check if the machine supports your snack types before buying.

How do I know if my packaging machine meets food safety rules?

Look for certifications like CE, FDA, or ISO.

Ask your supplier for proof.

Read the machine manual for cleaning steps.

Safe machines protect your snacks and your customers.