Choosing the right food packaging machine helps you work faster. It keeps your products safe and saves money. If you choose the wrong machine, you might pay a lot for repairs. You could have many breakdowns and waste a lot of packaging. Slow production can make you lose money. You might get fined if your machines are not clean. Some common problems are slowdowns, wrong labels, and wasted materials. To stop these problems, follow a step-by-step guide. Learn the basics about packaging machines. Make sure the machine fits your needs and budget. Check if the supplier gives good help. This way, you can make good choices and keep your business strong.

Risks of poor packaging machine selection:

Wasted packaging and lost products from mistakes.

Problems with quality like leaks or wrong labels.

Higher worker costs and less ability to change.

Key Takeaways

Learn your product’s size, shape, and packaging style first. This helps you pick the right machine. It also helps you avoid expensive errors. - Make sure the machine’s speed fits your production needs. The automation level should match your business plans. - Choose machines that are flexible and strong. They should also be safe. This keeps your packaging line working well. - Think about all costs before you buy. This includes the price, upkeep, and energy use. This helps you spend money wisely. - Pick a supplier with a good name. They should offer support and a warranty. This way, you get help when you need it.

Packaging Needs

Picking the best food packaging machine starts with knowing what you need. You should think about your product and your goals. You also need to choose the packaging style you want. Every part of your packaging line depends on these choices. Planning well helps you avoid mistakes and keeps things running well.

Product Features

Your packaging line should match your product’s features. Each product has its own size, shape, weight, and how easy it is to break. These things change how your packaging line works and what machines you need.

Size: Big products and small products need different machines.

Shape: Odd shapes might need special feeding systems.

Weight: Heavy items need strong packaging and tough machines.

Fragility: Soft or breakable products need gentle handling.

You also need to think about what your product is like. Liquids, powders, granules, solids, and pastes all need different machines. Thick liquids need special filling machines. Fragile products need gentle handling in your packaging line. The temperature and how harsh your product is can change what machine materials you need. These things are important when buying packaging machines.

Tip: Write down your product’s features before you look at machines. This helps you pick the right one and avoid problems later.

Volume and Throughput

How much you make and how fast you work shape your packaging line. Small businesses often use semi-automatic or tabletop machines. These work well for small amounts and let you change things as you grow. Big companies need fully automatic machines to keep up.

How much you make decides how much you spend.

How fast you work sets the speed and how well your line works.

New businesses might start with tabletop machines, but these can get too slow if you grow fast.

Semi-automatic machines can grow with your business. You can add more parts or upgrade to full automation.

Your packaging line should fit your space and be clean.

Being able to grow is very important when buying packaging machines. You want a line that can get bigger as your business grows. Machines that are easy to upgrade help you keep up with changes. Speed and how much you make should match your goals. This keeps your line working well and saves money on workers.

Packaging Style

The packaging style you pick changes your whole packaging line. Flexible packaging is very popular for food. Pouches, films, and foil have many good points. Pouches are useful and keep food fresh. Flexible films come in many types and work for bags, blister packs, and protection. Foil keeps out air, light, and water, so food lasts longer.

Your packaging line must work with these materials. Machines need to handle soft, layered, and custom materials. More flexible packaging means you need special equipment. These machines must work with new materials quickly and safely.

Being green is also important. Many brands use recyclable, compostable, or biodegradable materials now. Your packaging line must handle these without problems. Smart packaging is growing too. Some packages use QR codes, RFID tags, or freshness signs. Your packaging line must support these things.

Note: Always check if your packaging line can handle the materials and styles you want. This helps you avoid expensive changes later.

When you plan your packaging line, think about these things:

Product features (size, shape, weight, fragility)

How much you make and how fast you work

Packaging style and materials

These steps help you build a strong packaging line. You will reach your goals and keep your products safe. Good planning and the right packaging line make your business work better and ready to grow.

Food Packaging Machine Types

To pick the right food packaging machine, you need to know the main types. Each type works best for certain products and packaging needs. There are many choices, and each one has special features. If you use a buying guide, you can find the best machine for your business.

Automation Levels

You can choose manual, semi-automatic, or automatic packaging machinery. Automatic machines help you work faster and make fewer mistakes. These machines do jobs that are boring or hard for people. This means you need fewer workers. Your packaging line will run better. Fully automated systems keep the speed steady and quality high. You also lower the chance of injuries and save money on training. Many companies pick automatic machines to meet demand and fix worker shortages.

Tip: If your business is small, start with semi-automatic machines. You can switch to automatic packaging machinery when your business grows.

Common Machines

There are many types of packaging machines in the food industry. Each machine does a different job in your packaging line. Here is a table that shows the main types and what they do:

Machine Type | Description | Typical Applications |

|---|---|---|

Filling Machines | Fill containers by volume or weight | Food, beverage, sauces |

Bagging Machines | Pack food in bags, form, fill, and seal | Snacks, grains, powders |

Capping Machines | Seal bottles with different caps | Drinks, syrups, oils |

Lidding Machines | Place lids on containers | Ready meals, dairy |

Sealers | Vacuum or carton sealers for safety and freshness | Meat, cheese, bakery |

Checkweighers | Check product weight for quality control | All food sectors |

Make bags from film, fill, and seal in one step | Hygienic, continuous packaging | |

Vacuum Sealers | Remove air to keep food fresh longer | Meat, cheese, prepared foods |

You should learn about these packaging machines before you buy one. A buying guide helps you compare and pick the best packaging machinery for your needs.

Specialized Equipment

Some packaging machinery is made for special products or unique packaging. You might need modular machines that change size or shape fast. These machines help with single-serve pouches, airtight containers, or eco-friendly packaging. There are machines for powders, liquids, granules, or even fancy packaging like glass or metal. Specialized packaging machinery helps your brand and follows strict rules.

Premade pouch filling and sealing machine

Granule, powder, and liquid packaging machines

Flow wrap and form fill seal machines

Can seamers and tamper evident sealers

You have many choices to build a strong packaging line. Learn about the types of packaging machinery. Match them to your product and packaging style. This step makes your packaging line work well and ready to grow.

Key Features

Speed

Speed is very important for your packaging line. If you want to make a lot of products, you need fast machines. Most top food packaging machines can do 25 to 40 units each minute. For example, a granola line can pack 40 bags in one minute. A blister pack line can do 25 cartons in a minute. Fast machines help you finish orders on time. This keeps your customers happy. When you look at machines, always check how fast they are. Speed affects how well your whole line works. If a machine is slow, it can slow down everything. This can make you lose money.

Flexibility

Flexibility helps your packaging line work with many products. You can use different sizes, shapes, or materials without waiting long. Flexible machines let you switch jobs quickly, sometimes in just minutes. You can pack big or small packages, paper or plastic, on the same line. Flexible machines help you keep up with new trends and what customers want. Some machines can handle up to 100 pack styles, like bags or jars. This makes your equipment last longer and keeps your line strong as your business changes.

Tip: Flexible packaging lines save space and mean you need fewer machines.

Durability

Durability means your packaging line will last for years. Pick machines made from stainless steel. These do not rust or wear out as fast as coated steel. Clean your machines often and do regular checks and oiling. This helps them last longer. Do not let machines run too long without breaks. Choose machines you can upgrade as your needs change. Durable machines cost less to fix and keep your line working well.

Strong materials

Upgradeable designs

Good technical help

Safety

Safety is very important for any packaging line. Your machines must meet world safety rules like SQF, HACCP, BRCGS, and FSSC 22000. These show your line follows strict food safety rules. They need regular checks and good cleaning. Look for machines that follow GMP and ISO 22000 too. Safe machines protect your workers and your products. Meeting these rules helps you sell in more places and makes customers trust you.

Certification | Description | Applies to Packaging Line |

|---|---|---|

SQF | Food safety and quality management | Yes |

HACCP | Hazard control and hygiene | Yes |

BRCGS | Food safety and legal compliance | Yes |

FSSC 22000 | Global food packaging safety | Yes |

When you pick your packaging line, think about speed, flexibility, durability, and safety. These things help your line work better, keep your products safe, and help your business grow.

Packaging Materials

Picking the right packaging materials is very important. You should think about how strong the materials are. You also need to think about the environment and your brand. Good materials help your machines work well. They also keep your products safe.

Sustainability

Many food businesses now care about using sustainable packaging. You can choose materials that are good for the earth. These materials must also work with your machines. Some common packaging materials are plastic films, aluminum foil, biodegradable plastics, and paper-based materials. Each material has good and bad points.

Plastic films are bendy and let you pack things fast. But you must check the thickness so they do not rip or seal badly.

Aluminum foil keeps out light, air, and water. This helps food stay fresh longer.

Biodegradable plastics and paper-based materials are better for nature. But they might need special machine settings.

Note: Packaging materials must follow food safety rules. They should also work with tracking tools like barcodes or RFID tags. You need to think about recycling and waste rules when you pick materials.

You have to balance cost, how well machines work, and waste. Machines that use new materials, like compostable films, help you get ready for new trends.

Brand Appeal

The packaging materials you pick change how people see your brand. Good materials look and feel nice. This makes your product stand out. Many shoppers want packaging that feels good and looks cool. If you use cardboard, people may think your product is greener. They may also think it costs more than plastic.

Packaging also shows your brand story. The materials you use show if you care about the earth or want a fancy look. Good packaging materials help people trust your brand. They also make your product easy to find on the shelf. When your packaging matches your brand values, you connect with customers and sell more.

Costs

When you plan to buy packaging machinery, you need to think about all the costs. The price you pay at first is not the only cost. You also need to think about maintenance, energy use, and if you want new or used equipment. These things help you know the total cost of owning a machine.

Purchase Price

The first thing you notice is the purchase price. New packaging equipment can cost from $10,900 for a simple manual model to $65,000 for big automatic machines. Used machines usually cost 30-70% less than new ones. The table below shows starting prices for different models:

Machine Model | Starting Price (USD) | Production Capacity (cycles/min) | Key Features / Notes |

|---|---|---|---|

MSTS 1012 | $10,900 | 1-4 | Entry-level manual, good for low to medium production, adaptable tooling |

MRTS 1418 | $19,900 | 1-6 | Medium production, automatic scrap rewind, good for catering or grocery packaging |

AITS 1215 | $35,500 | 1-15 | Medium volume, automation features, optional MAP capability |

RTS4/MAP-1015 | $49,900 | 1-15 (without MAP), 1-8 (with MAP) | Modified atmosphere packaging (MAP) capable, medium to high production |

RBF6-1520 | $45,000 | 1-18 | Rotary type, medium to higher volume, has more sealing stations |

RBFA6-1520 | $65,000 | 1-18 | Rotary type with lid feeder and package unloader, higher volume production |

Maintenance

Maintenance is a big part of the cost of using packaging machinery. You should plan to spend about 3–5% of the purchase price each year for upkeep. For example, if your machine costs $20,000, you might spend $600 to $1,000 each year on maintenance. Small machines like sealers may only cost a few hundred dollars a year. Large machines, like palletizers, can cost thousands each year. Service contracts and spare parts add to these costs but help keep your line working.

Energy Use

Energy use is another important cost to think about. New packaging machinery uses sensors and smart systems to use less energy. Some machines reuse waste heat to save money. If you use energy-saving motors, you can save about 13% on energy. The kind of packaging material also changes how much energy you use. For example, glass needs longer pasteurization and uses more energy, while polypropylene is more efficient.

Packaging Material | Pasteurisation Time (minutes) | Sealing Machine Power Consumption | Overall Energy Consumption Impact |

|---|---|---|---|

Glass | 50 | Lower power sealing machine | Highest energy use because of long pasteurisation and heavy packaging |

Tin-Steel | 35 | Lower power sealing machine | Moderate energy use because of pasteurisation time and sealing power |

Polypropylene | 15 | Higher power sealing machine | Energy use is like tin-steel because of higher sealing power, but it is the most energy-efficient option |

Used vs. New

You can pick between new packaging equipment and used machines. Used machines cost less and are often ready to ship. You save money and can start faster. But used machines may need more repairs, have older technology, and less support. You might not get a warranty. There could be hidden problems or contamination. If you buy used, always check the machine and buy from someone you trust.

Advantages of used machines:

Lower first cost

Shorter wait time

Good quality if checked

Disadvantages:

More repair and setup costs

Fewer new features

Possible hidden damage or contamination

Tip: Always look at the total cost, not just the price you pay at first. Think about long-term costs, energy use, and how easy it is to get parts and service. Smart choices now can save you money later.

Supplier Comparison

Picking the right supplier is very important. The supplier you choose matters as much as the machine. A good supplier helps you avoid problems. They help your business run well. You should look at three things: reputation, support, and warranty.

Reputation

You want a supplier people trust. Check how long they have worked in packaging. More years means more experience and better service. Read reviews from other customers. Look at case studies to see their work. Happy customers mean the supplier is good.

Here are some things to check about a supplier’s reputation:

Read what clients say and look at case studies.

See if they have certifications like ISO 9001.

Make sure they are honest about how they work.

Check if they have a skilled design team.

Look at feedback on service, delivery, and price.

Criteria | Description | Importance |

|---|---|---|

How many years in packaging business | High | |

Quality Certifications | Certifications like ISO 9001 for quality | High |

References and Reviews | What past clients say about them | High |

Customer Support | Help with questions and problems | Medium |

Sustainability Practices | If they use eco-friendly ways to make products | Medium |

A supplier with a good name helps you avoid mistakes. They are reliable and help your business.

Support

After you buy your machine, you need help. Good suppliers teach your staff how to use the machine. They show you how to fix small problems. You should get help with maintenance and repairs. This keeps your machine working and saves time.

Look for suppliers who offer:

Maintenance to keep your machine working well

Fast parts replacement so you do not wait long

Help with fixing problems

Training for safe and easy use

Ongoing help to keep your business running

Tip: A supplier who gives good support is like a partner, not just a seller.

Warranty

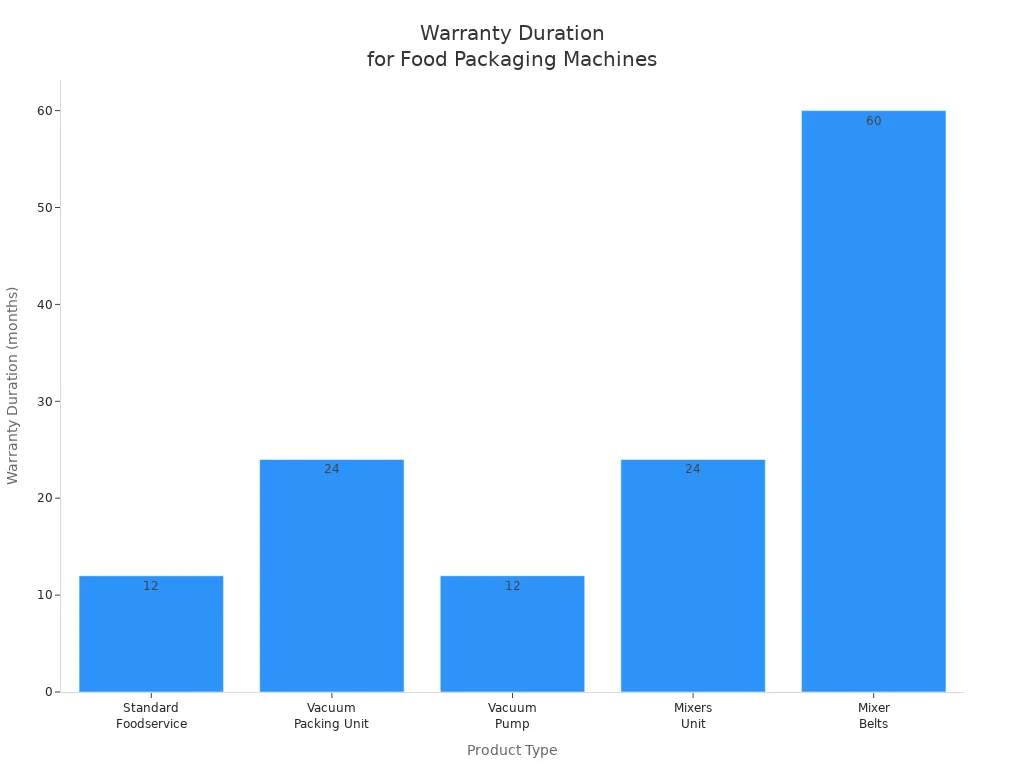

A good warranty protects your money. Most top suppliers give warranties for defects in materials and work. Some last one year, others last two or more. Always read the warranty rules. Some do not cover mistakes by users or normal wear.

Here is a table showing how long warranties last:

Supplier/Product Type | Warranty Duration | Coverage Highlights |

|---|---|---|

Vollrath - Standard Foodservice Products | 12 months parts & labor (end user) or 18 months (dealer) | Covers defects in materials and work; does not cover wear parts, user mistakes, or wrong use |

Vollrath - In-Chamber Vacuum Packing Machine | 2 years (unit), 1 year (pump) | Does not cover wear parts like sealing wire, tape, gasket |

Vollrath - Mixers (entire unit) | 2 years | Warranty is void if you misuse it or overload it |

Vollrath - Mixer Belts | 5 years | Same exclusions as mixers unit |

Always ask if spare parts are easy to get. Quick parts mean less waiting for repairs. A strong warranty and easy parts show the supplier cares about your success.

Staff Training

Training your staff is very important for your food packaging line. When workers know how to use machines, there are fewer mistakes. This means less time when machines are not working. Trained workers help you make more products and keep them safe.

Operation

Operators must know how each part of the machine works. Start by teaching the basics first. Show how the system works and how parts fit together. Teach simple things before moving to harder steps. This helps everyone understand the whole process.

Let workers practice using the machines. They should change settings and work with real products. Workshops and digital practice help them learn faster. Vendors can also teach your team new skills. When operators practice, they notice problems early. They can hear strange sounds or see leaks. They fix small issues before they get worse.

Operators who know what to do keep the line running. They help keep products safe and waste less material.

Maintenance

Learning how to care for machines is as important as learning to use them. Teach your team when and how to check machines. Show them what warning signs to look for, like slow speed or weird noises. Fixing problems early stops bigger issues.

A good training plan should include:

Cleaning and checking machines

Knowing when to change parts

How to fix common problems

Safety steps for repairs

Keep teaching your team with new lessons and support. When you help workers learn, machines last longer. You also stop expensive breakdowns. Workers feel important and skilled when they learn more.

Training Focus | Key Benefits |

|---|---|

Operation | Fewer mistakes, more products made |

Maintenance | Less downtime, machines last longer |

Ongoing Learning | Learns new tech, keeps skills sharp |

Good training helps your team work better together. It makes your workplace safer and helps you make more products. Training your staff is a smart way to keep your line running well.

Benefits

Picking the right packaging machine helps your business in many ways. You will work faster and make better products. Your business can grow over time. When your machine fits your needs, your packaging line works well.

Efficiency

A good packaging machine lets you pack things quickly. You need fewer workers and pay less for extra hours. Many companies have seen big improvements after getting new machines:

A dairy and cheese company stopped using other packers. They made new products faster and sold them in more places.

A flour company used automation and sold three times more. They also paid less for workers and packed better.

An OTC medicine company fixed slow spots and saved money by using automated packaging.

You can also get these good results:

Fewer mistakes and less waste

Machines check for errors and fix them fast

Lower energy bills, saving up to 40% with better motors

These benefits help you save money and do better work.

Product Quality

A packaging machine keeps your products safe and fresh. It seals out air, water, and germs. This makes food last longer and taste better. Machines fill and seal each package the same way. Every item looks and weighs the same. You throw away less spoiled food. Less touching by people means cleaner products and fewer mistakes. The right machine also helps you follow safety and quality rules.

Business Growth

The right packaging machine helps your business get bigger. You can pack more products and try new packaging styles. Flexible machines let you switch between products fast. You can keep up with new trends and what customers want. If you plan well, you can upgrade your machine later without spending too much. Automation helps you grow and stay ahead of others. Following safety and green rules keeps your brand safe and lets you sell in more places.

Factor | Benefit for Growth |

|---|---|

Handles new products and packaging styles | |

Throughput | Packs more products without slowdowns |

Maintenance | Less downtime and lower costs |

Automation | Saves on workers and packs the same way |

Compliance | Stops recalls and builds trust |

When you buy the right packaging machine, you get many good things. You work faster, make better products, and help your business grow. The benefits of packaging machines help your whole business, not just the packaging line.

Decision Matrix

Checklist

A decision matrix helps you compare food packaging machines side by side. You can use a checklist to make sure you look at all important points. This tool lets you see which machine fits your needs best. Start by listing your main considerations. Think about production needs, space, and workforce skills. Add budget and return on investment to your checklist. Include cost for purchase, maintenance, and energy.

Here is a sample checklist you can use:

What is your production volume?

Does the machine fit your product type and packaging style?

How much space do you have for the machine?

What is the total cost, including purchase, maintenance, and energy?

Can the machine handle future upgrades or changes?

How easy is it to operate and maintain?

Does the supplier offer good support and training?

What is the expected return on investment?

Are there hidden costs or extra fees?

Does the machine meet safety and quality rules?

Use this checklist to compare each machine. Give each item a score. Add up the scores to see which machine matches your needs best.

A good checklist also includes a cost-benefit analysis. Look at the total cost of ownership, not just the price tag. Think about hidden costs, like downtime or extra parts. This guide helps you make a smart choice.

Expert Advice

Experts say you should always start with a clear checklist. Know your product and your production needs. Machines work best when you match them to your product type, output, and packaging format. Vertical form fill seal machines work well for many foods. Automatic machines cost more at first but save money over time. Semi-automatic machines cost less and are good for small businesses.

Experts also suggest these considerations:

Give suppliers detailed information about your product.

Ask about machine changeover for different package sizes.

Check if the machine can grow with your business.

Ask about support and spare parts.

Think about the cost of training and setup.

Talk to expert teams before you buy. They can guide you through the checklist and help you avoid costly mistakes.

A good guide and a strong checklist make your decision easier. You will see all considerations and costs clearly. This approach helps you pick the best machine for your business.

Case Studies

Success Stories

You can learn a lot from companies that pick the right food packaging machines. One big snack company worked with Viking Masek to make their packaging line better. They used a full automated system with fast bagging and case packing. The results were very good:

Aspect | Details |

|---|---|

Company | National snack food producer partnering with Viking Masek |

Implementation | Turnkey automated snack packaging system with high-speed bagging and case packing lines |

Outcomes | - Production doubled |

Lessons Learned | - Seamless integration and post-sale support are critical |

Additional Benefits | Improved accuracy, efficiency, and customer satisfaction without increasing headcount |

This company did more than just work faster. They made fewer mistakes and wasted less packaging. Workers got new jobs instead of losing them. The company learned that training and support are just as important as the machine. You should find suppliers who give both.

Smart sensors and automation help many companies do well. These sensors change settings when products change. They keep machines working smoothly. For example, photoelectric sensors can find products even if they look different. Vision systems check size and find problems before packing. Barcode scanners read codes, even if they are scratched. These tools help you stop mistakes and keep quality high.

Common Mistakes

Many companies make the same mistakes when picking packaging machines. Some skip training or buy machines that cannot grow with their business. Others forget that new machines can change workers’ jobs. Some do not think about getting help after buying the machine.

Tip: Always plan for training and future growth. Make sure your supplier offers help after you buy the machine.

If you use too many manual changes, you might have more mistakes and downtime. Bad quality control can waste products and upset customers. Smart automation and regular training help you avoid these problems. When you care about both technology and people, your packaging line will work better and last longer.

You should always use a step-by-step approach when you select a food packaging machine. Think about your product needs, machine features, and the total cost. Do not forget to check the cost of maintenance and the cost of energy use. Compare the cost of new and used machines. Good supplier support can lower your long-term cost. Use checklists and talk to experts. These steps help you control cost and make smart choices for your business.

FAQ

What is the most important thing to consider when choosing a food packaging machine?

Pick a machine that matches your product and how much you make. Think about how fast it works and if it is safe. Make sure it is easy to use. Check if it fits in your space and if you can afford it.

How often should you maintain your packaging machine?

Follow the plan in your machine’s manual. Most machines need a check every week. You should do a deep clean once a month. Regular care stops breakdowns and keeps things running well.

Can one machine handle different packaging materials?

Some machines work with plastic, paper, or foil. Look at the machine’s specs to be sure. Flexible machines let you change materials fast. Ask your supplier for a list of what works.

Do you need special training to use a packaging machine?

Yes, you must learn how to use and care for the machine. Good suppliers teach your team how to use it. Training helps you make fewer mistakes and keeps products safe.

Is it better to buy a new or used packaging machine?

New machines have the newest features and a warranty. Used machines cost less but might break more. Always check the machine’s shape and if you can get help before you buy used.