Modern fertilizer packaging machines, like Henll’s semi-automatic powder filling and packaging machine, fix dust and accuracy problems right away. Picture a worker using organic fertilizer equipment in a busy factory. Before, dust clouds filled the air, but now the fertilizer stays inside. The machine puts the right amount of fertilizer in each bag. Safety gets better, and the fertilizer goes to customers without being wasted. Clean packaging is important for every fertilizer maker.

Key Takeaways

Modern fertilizer packaging machines help lower dust in factories. This makes the workplace cleaner and safer for everyone. Enclosed chambers and dust-tight valves stop dust from getting out. This protects workers and keeps the product safe. Accurate weighing systems make sure each bag has the right amount. This cuts down on waste and helps customers trust the product. Automation features make the packaging process faster and easier. Workers can then focus on doing their jobs well. Self-cleaning parts in these machines save time on maintenance. This helps everything run without problems. Advanced sensors watch the process in real time. They find and fix problems quickly during packaging. Using modern machines saves money by cutting waste and repairs. Henll’s machines follow European rules for dust control and accuracy. This makes them a good choice for fertilizer makers.

Fertilizer Packaging Machine Challenges

Dust Problem

Causes

Factories that use organic fertilizer equipment often have a lot of dust. When workers move ultrafine powders, dust can float up easily. In a busy plant, a worker pours powder into a hopper. Fine particles escape and make a cloud you can see. This happens because the particles are very light and dry. Doing things by hand, like scooping or moving fertilizer, makes more dust. Even a small breeze or a shake can spread dust everywhere. Making organic fertilizer creates more dust since the materials are loose and powdery.

Impact

Dust does not just make the factory dirty. It can cause real trouble for workers and nature. Breathing dust every day can cause coughing or allergies. Sometimes it can even hurt your lungs. Dust settles on machines and floors, making them slippery and unsafe. Fertilizer dust can get outside and hurt plants or water nearby. If dust lands on the fertilizer, it can change its quality. Customers might get bags that are not as clean or pure as they want. Too much dust in the air can also break machines faster. This means more repairs and higher costs for the company.

Tip: Controlling dust helps keep workers and nature safe. Clean factories also make better fertilizer.

Accuracy Issues

Variability

Accuracy problems happen a lot when packing fertilizer. The main reason is that fertilizer pieces are not always the same size. Some break apart during the process. This makes it hard to measure the right amount each time. Imagine a worker using a scoop to fill bags. One scoop might have more powder, another has bigger chunks. The weight changes from bag to bag. This means some customers get less fertilizer, others get too much. Over time, this wastes product and money.

Human Error

Manual packaging also means people can make mistakes. Workers can get tired or lose focus during long shifts. They might forget to check the scale or read numbers wrong. Sometimes they rush to finish orders and miss small mistakes. Even small errors add up when packing hundreds of bags. These mistakes hurt the fertilizer company’s reputation. Customers want to trust that every bag has the right amount inside.

A modern fertilizer packaging machine fixes these problems with sensors and automation. It keeps dust inside and measures each bag very carefully. This means safer work, cleaner products, and happier customers. For more about how these machines work, check out our Semi-automatic Powder Filling And Packaging Machine.

Sealed Systems

Dust Control

Enclosed Chambers

Think about a fertilizer factory from before. Workers had to wear masks all day. Dust filled the air every time they packed a bag. Now, Henll’s semi-automatic powder filling and packaging machine makes things better. The machine has enclosed chambers that keep fertilizer inside. Workers stand by the machine, but they do not see dust anymore. The chamber works like a shield and stops fine particles from getting out.

Henll’s design uses dust-tight valves made from strong polymers. These valves close the chamber each time a bag is filled. They stop dust from leaking, even when the machine works fast. European machines also use enclosed chambers. But Henll’s special degassing spiral technology is different. The spiral takes out extra air from the powder. This means less dust forms when filling bags.

Note: Enclosed chambers help keep air clean. They protect workers from breathing in bad particles.

Airlocks

Here is another example. In a busy line, a worker puts fertilizer into the hopper. The machine uses airlocks to keep the chamber closed. When the hopper opens, the airlock shuts off the rest of the system. This keeps dust from getting out into the factory. Henll’s machine has loading spouts with filters built in. These spouts make a closed loading cycle, so dust stays inside.

European machines use airlocks too. Both types try to keep the process sealed. Henll’s machine is special because it uses airlocks and in-line filtration units together. These units pull dust from the air and send clean air back. Workers see the change right away. The factory is cleaner, and machines last longer because dust does not build up.

Key features in sealed systems:

Enclosed chambers keep dust inside.

Dust-tight valves stop leaks.

Airlocks close off parts during loading.

In-line filtration units catch dust and clean the air.

Henll’s sealed system meets European dust control standards. The machine’s dust removal and degassing device work together to lower dust pollution. Factories using Henll’s machine have cleaner floors, safer air, and better products.

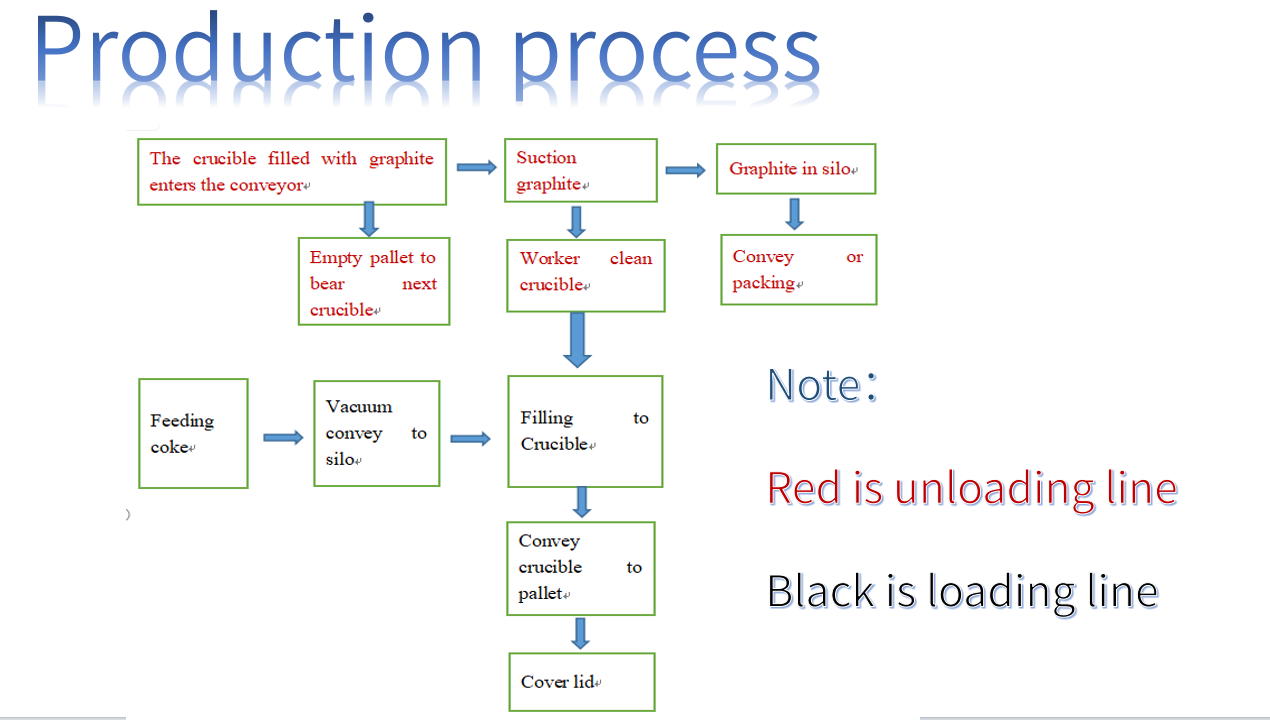

For more about how Henll’s technology keeps workers safe, visit the Graphite pitch powder crucible loading & unloading system.

Dust Extraction Solutions

Modern fertilizer packaging machines have a big dust problem. When workers pour fertilizer or move bags, dust gets in the air. This dust makes the factory dirty. It can also hurt workers and make fertilizer worse. Henll’s fertilizer packaging machine uses special dust removal devices to fix this.

Dust Pollution Reduction

Filtration Units

Factories with organic fertilizer equipment often have dust everywhere. Picture a worker in a busy plant. He fills bags, and fine powder goes into the air. The factory puts in a dust collector room with filtration units. These units catch dust before it spreads. Henll’s machine has a self-returning dust removal system. This system pulls dust from the air and sends clean air back. The filtration units trap tiny particles, so workers breathe better.

Here is a table with some dust collector equipment used in fertilizer packaging:

Technology Type | Description |

Dedusting bag filter system | Filters dust made during fertilizer production to keep the workshop clean. |

Cyclone dust collector | Uses spinning force to separate dust from air, good for high-dust places. |

Centrifugal blower | Moves air and dust, helping remove dust from the area. |

Exhaust gas scrubber (FRP) | Cleans exhaust gases, lowering dust and pollutants in the air. |

Ventri washer (FRP) | Uses water to catch dust, making air better in the workspace. |

A real example comes from a fertilizer plant that changed to Henll’s machine. Before, workers saw dust clouds every day. After adding new filtration units, the air got clear. The plant met tough environmental rules and workers felt safer.

Tip: The right dust collector equipment keeps the factory clean and helps meet environmental rules.

Self-Cleaning Mechanisms

Dust removal does not end with filters. Henll’s fertilizer packaging machine has a self-cleaning system. This system works like a smart vacuum. When dust builds up, the machine cleans itself. The self-returning dust removal system collects dust and sends it back to use again. This means less waste and lower costs.

The special degassing device in Henll’s machine also helps a lot. When the machine fills a bag, the degassing spiral takes out extra air from the fertilizer. This keeps the powder steady and stops dust from floating up. The machine works well, even with very fine powders.

Let’s see the environmental and safety benefits of these dust removal systems:

Benefit | Description |

High-Efficiency Purification | Removes over 99.9% of dust, helping meet emission rules. |

Material Recovery | Collected dust can be used again, cutting waste and costs. |

Stable Operation | Automation handles lots of air and dust, so work does not stop. |

High Flexibility | The design fits many production needs and fertilizer types. |

A case study from another fertilizer company shows the change. The company used to spend hours cleaning dust from machines and floors. After using Henll’s self-cleaning system, cleaning time was cut in half. Workers spent more time on important jobs, and the factory stayed cleaner.

Note: Dust removal devices keep workers safe and help save money. Cleaner air means fewer health problems and better fertilizer.

For more about how Henll’s dust removal solutions work, visit the fertilizer packaging solutions page.

Precision Weighing

Modern fertilizer packaging machines make work easier for factories. Long ago, workers used scales and scoops. They guessed the weight and hoped it was right. Now, machines like Henll’s help every bag have the right amount. These machines use smart sensors and controls to do the job well.

Advanced Sensors

Load Cells

Imagine a busy factory with organic fertilizer equipment. Workers fill bags with fertilizer all day. Before, they checked each bag by hand. Sometimes, the weight was wrong. Henll’s fertilizer packaging machine uses load cells to fix this. Load cells are sensors that measure weight very well. When a worker puts a bag on the machine, the load cell checks the weight right away.

Advanced sensors help stop weighing mistakes.

The machine can be very precise in fertilizer bagging.

A weighing sensor makes sure big bags get the right amount.

Factories notice the change quickly. Bags have the same weight every time. Customers trust the product more. Workers spend less time checking and more time packing.

Dynamic Adjustment

Henll’s machine does more than just measure. It changes how it fills bags while working. Imagine a worker watching the machine fill a bag. The control system checks the weight and fixes it if needed. It uses smart math like PID to see if the bag is too light or heavy. The machine sends signals to the servo motor. The motor changes speed and angle to get the weight right.

1) The control system uses set weights and real-time data to make quick changes.

2) It sends signals to the servo motor driver for good speed and angle control.

3) The machine can switch between fast, slow, and stopping at the right time.

4) The servo motor is the main power and control part.

5) Automatic calibration fixes weighing mistakes and keeps things smart.

A fertilizer plant started using Henll’s machine last year. Before, workers had to fix the filling by hand. Now, the machine does everything. The plant saw less waste and more accurate bags. The manager said, “We used to lose money on mistakes. Now, every bag is perfect.”

Accuracy Control

Real-Time Monitoring

Henll’s fertilizer packaging machine watches every step. The sensors and control system check the weight as the bag fills. If something goes wrong, the machine stops and tells the worker. This real-time monitoring means fewer mistakes and better quality.

A worker in a fertilizer factory saw the change. He said, “I used to worry about dust and wrong weights. Now, the machine tells me if something is wrong. I feel safer and the product is better.”

Data Logging

Factories need to know how much fertilizer they pack each day. Henll’s machine saves all the data. It records the weight of each bag and notes any changes. Managers can look at the records to see if things are working well. If there is a problem, they can fix it fast.

Here is a table showing what the machine tracks:

Feature | Description |

Bag Weight | Records the weight of each bag |

Filling Speed | Tracks how fast bags are filled |

Error Alerts | Logs any mistakes or problems |

Calibration Data | Keeps records of adjustments |

Factories use this data to make their process better. They can find problems and fix them before they get big.

Comparing Accuracy: Henll vs. European Standards

Henll’s fertilizer packaging machine is as good as European models. Both use smart sensors and servo motors. Henll’s machine is very precise, just like top European machines. The automatic calibration and real-time monitoring help Henll do even better.

A fertilizer company compared Henll’s machine to a European one. Both machines packed bags with almost no mistakes. Henll’s machine worked faster and needed less checking. The company saved money and got cleaner, more accurate fertilizer bags.

Tip: Precision weighing means less waste, better products, and happier customers.

Automation and Controls

Modern fertilizer factories want machines that are simple to use. They also want machines that work well every day. Henll’s semi-automatic powder filling and packaging machine is special. It has smart automation and easy controls. These features help workers do their jobs better.

PLC Systems

User Interface

Imagine a new worker at a fertilizer plant. He stands by Henll’s machine and sees a bright touch screen. The screen has big buttons and clear numbers. He touches the screen to start filling bags. The PLC system is like the machine’s brain. It collects data from sensors and makes fast choices. The worker can see the weight, speed, and bag count right away. If there is a problem, the machine shows a warning fast.

Here is a table with important PLC control system features:

Feature | Description |

Intelligent Control System | Uses weighing, sensors, and PLC for full automation |

Automatic Control | Runs feeding, bag clamping, and unloading by itself |

Parameter Settings | Lets users set weights and see changes |

Real-time Monitoring | Shows filling, sealing, and stacking as they happen |

Remote Control | Lets people run the machine from far away |

Fault Alarm Functions | Warns users about problems for quick fixes |

Tip: A simple interface helps new workers learn quickly and make fewer mistakes.

Customization

Factories pack many kinds of fertilizer. Sometimes, they need to switch from powder to compost. The supervisor changes the settings on the screen. The machine moves the filling head and changes the bag size. No tools are needed. The PLC system saves programs for each fertilizer type. This makes switching fast and easy.

The machine works with compost, powdery, and granular fertilizers.

Workers can change bag sizes and materials.

The system fits both organic and compound fertilizer lines.

For more about how the machine adapts, visit the our official website.

Maintenance

Predictive Features

Factories cannot stop for long repairs. Henll’s machine has predictive maintenance features. The PLC watches how the machine works. If a part is wearing out, it sends a warning. The maintenance team gets a message before anything breaks. This keeps the machine running and saves money.

Equipment Type | Benefit of Predictive Maintenance |

Packaging Machines | Keeps machines working, lowers contamination risk, and protects quality |

Easy Cleaning

After a long day, workers must clean the machine. Henll’s design uses stainless steel and smooth parts. The team can wipe the machine fast. There are no hidden places for powder to hide. The self-cleaning dust removal system helps too. Less dust means less cleaning work.

Here is a simple plan for keeping the machine working well:

1) Check the machine every week for worn parts.

2) Use only good parts for repairs.

3) Train all workers to use the machine right.

4) Keep the machine in its best working range.

5) Fix any alerts or problems quickly.

Note: Easy cleaning and smart warnings keep the factory running and workers happy.

Henll’s automation and controls make packaging fertilizer easy, safe, and flexible. Factories can pack many materials, switch jobs fast, and keep machines in good shape with less work.

Benefits and Comparisons

Efficiency

Productivity

A fertilizer factory in Jiangsu got a new packaging machine last year. Before, workers scooped fertilizer by hand for hours. Dust filled the air, and they stopped often to clean. After the new machine came, things changed a lot. The machine packed more bags every hour. Workers fixed fewer mistakes and kept the line moving. The automated system worked well with organic fertilizer equipment. The team handled bigger orders without feeling stressed.

Waste Reduction

The factory used to lose a lot of fertilizer when packing. Dust went into the air, and powder spilled on the floor. The new machine’s dust removal system kept dust inside the chamber. Less fertilizer was wasted, so the company saved money. The dust collector room filtered out fine particles. Workers could reuse what the machine collected. The manager saw that every bag had the right amount. Fewer bags needed to be packed again.

Safety and Quality

Workplace Cleanliness

Factories with fertilizer production equipment want clean workspaces. A plant in Guangdong had dust problems before switching machines. Workers wore masks, but dust still landed everywhere. After getting Henll’s machine, the dust stayed inside. The dust removal system filtered the air. The floors stayed clean. The team felt safer, and the plant passed more safety checks.

Here’s a table showing how modern machines help with cleanliness and consistency:

Benefit/Challenge | Description |

Dust Control | Automated systems use dust-control technology to keep the work environment clean and safe. |

Worker Safety | Reduces human contact with fertilizer, preventing direct exposure and minimizing injuries. |

Consistent Product Measurements | Ensures accurate filling, which eliminates waste and maintains product consistency. |

Improved Operational Efficiency | Automates processes to meet increasing market demands, enhancing overall productivity. |

Product Consistency

A fertilizer company in Shandong wanted every bag to weigh the same. Before, some bags had too much, and some had too little. Customers complained about the difference. After getting Henll’s fertilizer packaging machine, things got better. The machine’s sensors checked each bag and made quick changes. Every customer got fertilizer with the same quality and amount.

Henll vs. Europe

Technology Comparison

Henll’s machine uses a special degassing spiral and advanced dust removal. European machines also have sealed chambers and airlocks. Henll’s design is different because of its self-returning dust removal system. Both machines keep dust inside and protect workers. Henll’s machine matches European standards for accuracy and dust control. Automatic calibration and real-time monitoring help factories avoid mistakes.

Cost-Benefit

A fertilizer plant compared Henll’s machine with a European one. Both machines packed fertilizer with high accuracy. Henll’s machine worked faster and needed less fixing. The plant saved money on repairs and cleaning. The dust removal system reduced waste, so the company spent less on raw materials. The manager said, “We get the same quality as European machines, but we save more each month.”

A fertilizer plant started using Henll’s machine and noticed big improvements. The sealed system stopped dust from getting out. Dust removal technology made the air much cleaner for everyone. Precision weighing made sure each bag had the right amount inside. Automation let workers pack bags faster and with less risk. Experts say to check dust control, accuracy, and special features before picking a fertilizer machine. Henll’s machines are as good as European ones. To get the best results, factories should ask experts about their fertilizer needs.

FAQ

What makes Henll’s fertilizer packaging machine different from others?

Henll’s machine has a special degassing spiral. It also has a dust removal system that sends dust back inside. A plant in Jiangsu saw cleaner air and better bags after using Henll. The machine meets European rules for dust and accuracy.

How does the machine keep dust from escaping?

The machine has closed chambers, airlocks, and filters. Workers at a busy plant saw less dust after using Henll’s system. The sealed design keeps the workspace safe and clean.

Can the machine handle different types of fertilizer?

Yes, it can. Operators can switch between powder, compost, or granular fertilizer easily. One supervisor changed from organic to compound fertilizer in minutes. This saved time and made work easier.

How accurate is the filling process?

Henll’s machine uses smart sensors and checks weight as it fills. A factory in Shandong said every bag had the right weight. The system fixes itself, so each package stays the same.

Is the machine easy to clean and maintain?

Yes. The stainless steel body and smooth parts make cleaning easy. Workers at a Guangdong plant cleaned up in half the time after switching to Henll’s machine. The self-cleaning dust system also cuts down on daily work.

What safety benefits does the machine offer?

The sealed system and dust removal features keep workers safe from bad particles. One plant passed more safety checks after getting Henll’s machine. Cleaner air means fewer health problems for everyone.

How does the machine help reduce waste?

The dust removal system collects powder and uses it again. A manager in Jiangsu saw less fertilizer lost to spills and dust. The company saved money by reusing what was collected.

Can the machine track production data?

Yes. The machine saves bag weights, filling speed, and mistakes. Managers can look at this data to find problems or see patterns. This helps keep production running well.