If a company picks the wrong Carbon Black Packaging Machine, problems can happen. Workers may have to clean up messy spills. Some product could get wasted. The air might not be safe to breathe. Each powder needs its own care. Companies should think about airtightness. They should also think about dust control. Automation is important too. Good choices help keep work safe and easy.

Tip: Pick machine features that fit the powder and safety rules. This helps stop expensive mistakes.

Key Takeaways

Think about how much you need to pack. Also, think about bag sizes and powder types. This helps you stop problems later.

Pick machines that keep air tight and control dust. These keep workers safe and the area clean.

Find machines that work by themselves. This saves time and lowers worker costs. Machines that do things automatically make packing easier.

Look at how good the maker is and what warranty they give. A good company gives you quality and help you can trust.

Always look at many machines and ask for demos. This lets you see how each machine works and if it is right for you.

Define Your Packaging Needs

Choosing the right Carbon Black Packaging Machine starts with knowing what your business really needs. Every company works with different powders, bag sizes, and production goals. Taking time to think about these details helps avoid problems later.

Production Volume

Production volume means how much carbon black a company needs to pack each day, week, or month. Some factories run all day and night. Others only pack a few bags at a time. A small operation might not need a big, fast machine. A large plant needs a machine that can keep up with high demand.

Tip: Always plan for the future. If a company expects to grow, it should pick a machine that can handle more work later.

Packaging Type & Size

Carbon black comes in many forms. Some companies use small bags. Others use jumbo bags or bulk containers. The size and type of packaging matter a lot. A Carbon Black Packaging Machine should fit the bags a company uses most. It should also switch easily between sizes if needed.

Small bags work well for retail or small orders.

Jumbo bags are best for shipping large amounts.

Some machines can handle both, which adds flexibility.

Material Compatibility

Not every machine works with every powder. Carbon black can be very fine or a bit coarse. Some grades are light and fluffy. Others are heavy and dense. The machine must handle the exact type and grade of carbon black. If the powder is very fine, dust control becomes even more important. Airtight packaging keeps the product safe and stops leaks.

Note: Carbon black dust can be messy and even dangerous. Machines with good dust control and airtight seals protect workers and keep the factory clean.

Automation Level

Automation means how much of the process the machine does by itself. Some machines need a person to help with every step. Others fill, seal, and weigh bags automatically. High automation saves time and lowers labor costs. It also keeps workers safer by reducing contact with carbon black.

A company should think about:

How many workers it has

How much training they need

If it wants to run the machine all day without stopping

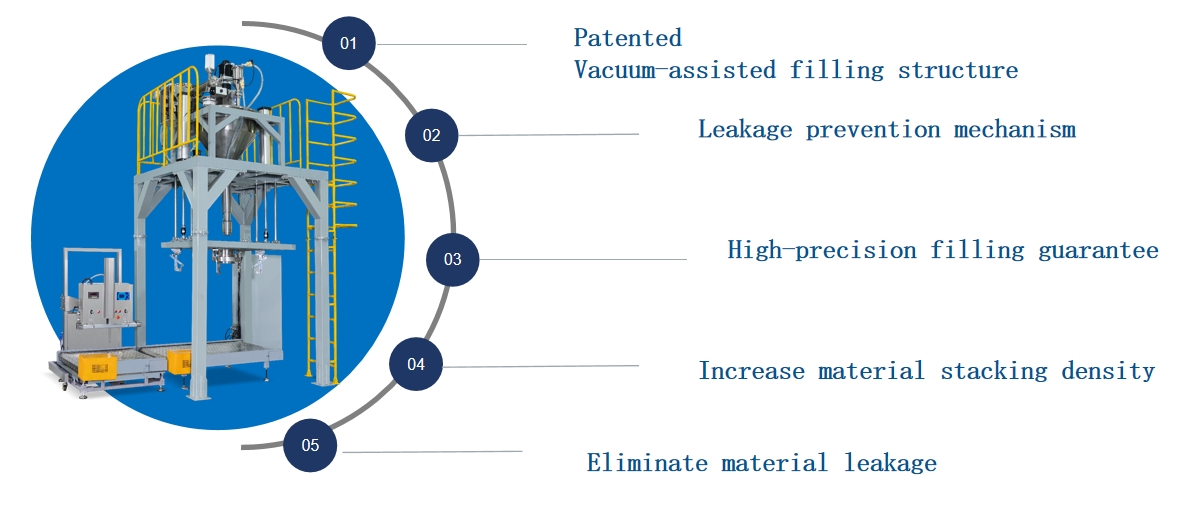

A fully automatic machine, like the Henll Full-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine, can make the whole process smoother and faster.

By looking at these four areas, companies can find a Carbon Black Packaging Machine that fits their needs today and tomorrow. This careful planning helps keep the workplace safe and the packaging process efficient.

Key Features in a Carbon Black Packaging Machine

Picking the right Carbon Black Packaging Machine means checking important features. Each feature helps make packing safe, clean, and fast. Here are the things you should look for.

Airtightness & Dust Control

Airtightness keeps carbon black inside the bag. Dust control stops powder from getting into the air. These features protect workers and keep the factory clean. Machines with strong seals and good dust systems work best. Henll’s Full-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine has a special dust removal system. This system catches tiny particles before they spread. Automatic degassing removes air during filling. This means less mess and safer air.

Tip: Always see if the machine has airtight seals and dust control. These features help keep people safe and the product good.

Filling Accuracy

Filling accuracy means the machine puts the right amount in each bag. Accurate filling stops waste and saves money. Some machines use sensors to measure powder as it fills. Henll’s machine uses quantitative filling technology. This helps every bag have the same amount. Companies can trust that each package has the correct weight.

Here’s why filling accuracy is important:

Benefit | What It Means |

|---|---|

Less Waste | No extra powder lost |

Consistent Bags | Every bag weighs the same |

Happy Customers | Buyers get what they expect |

Speed & Efficiency

Speed and efficiency help companies pack more bags faster. Fast machines keep up with busy factories. Efficient machines use less energy and need fewer workers. Henll’s Carbon Black Packaging Machine uses automation to make packing quicker. Operators can set the machine and let it work. The easy controls help change settings fast. This saves time and helps make more bags.

Note: Fast and efficient machines help companies grow. They also lower costs and make work easier.

Safety Systems

Safety systems keep workers safe from harm. Carbon black dust can be dangerous if it gets in the air. Machines with safety guards, alarms, and emergency stops protect everyone. Henll’s machine has a dust removal system and strong seals. These features lower health risks and keep the workspace clean.

A good Carbon Black Packaging Machine should have:

Emergency stop buttons

Dust shields

Alarms for leaks or errors

Maintenance Ease

Easy maintenance keeps the machine working well. Machines with simple designs and clear controls are easier to clean and fix. Henll’s machine uses stainless steel parts that do not rust or wear out fast. Operators can check and clean the machine without special tools. Quick maintenance means less downtime and more production.

Tip: Pick a machine that is easy to maintain. This saves time and money over time.

A Carbon Black Packaging Machine with these features helps companies pack safely, quickly, and accurately. Henll’s machine shows how new technology can make packaging better for everyone.

Evaluating Quality & Reliability

Picking a carbon black packaging machine is important. Companies want a machine that works well for many years. They also want to trust the people who make and fix the machine. There are three main things to check before buying.

Manufacturer Reputation

A good brand name is very important. Companies like Henll are known for making machines that work well. People in the business trust these brands. When a company chooses a famous brand, it feels safer. These brands often have special certificates. Certificates show the machines are safe and high quality.

Tip: Always pick brands with a good history and the right certificates. This helps stop problems in the future.

Warranty & Support

A strong warranty means the maker believes in the machine. If something breaks, a good warranty saves time and money. Support is important too. Companies need help with setup, training, and fixing problems. Henll gives help after the sale so customers feel sure about using the machine.

Here’s a quick checklist for warranty and support:

Clear warranty rules

Fast help when something breaks

Training for workers

Spare parts are easy to get

User Feedback

Feedback from real users is very helpful. People who use the machine every day know what is good and bad. Reading reviews or talking to users helps companies know what to expect. Many buyers share their stories online or at meetings. Good feedback means the machine works well in real life.

What to Look For | Why It Matters |

|---|---|

Positive reviews | Shows machine reliability |

Repeat customers | Proves long-term value |

Honest feedback | Helps set real expectations |

By checking these three things, companies can choose a carbon black packaging machine that works well and lasts a long time.

Cost & Value Considerations

Initial Investment

Buying a carbon black packaging machine is a big choice. Many companies look at the price first. Some machines cost more because they have better features. Some use stronger materials. Henll’s Full-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine uses stainless steel. It also has a tough frame. This helps the machine last longer and work better. Paying more at first can mean fewer problems later.

Tip: Check what comes with the machine. Does it have training, setup, or extra parts? These things can make the purchase worth more.

Operating Costs

After buying the machine, companies must think about daily costs. These costs include electricity, fixing, and workers. Machines with automatic systems, like Henll’s, need fewer workers. This saves money every month. Machines that are easy to clean also save time and cleaning supplies.

Here’s a quick look at common operating costs:

Cost Type | What to Watch For |

|---|---|

Labor | Number of workers needed |

Maintenance | Parts and repairs |

Cleaning | Time and supplies |

Utilities | Power and air use |

Energy Efficiency

Energy use is important for saving money and helping the planet. New machines use less power but do more work. Henll’s machine uses smart controls to save energy when filling and sealing. Using less energy means lower bills and less pollution.

Note: Energy-efficient machines help companies reach green goals and save money too.

Long-Term ROI

ROI means “return on investment.” Companies want to know if the machine will be worth it over time. A good machine packs more bags and has fewer problems. This means less waste and more products to sell. Henll’s machine is strong and has smart features. It helps companies get the most for their money.

Fewer breakdowns mean less time lost.

Accurate filling stops product loss.

Automation cuts labor costs.

A smart buy now can bring bigger savings and profits later.

Compliance & Safety Standards

The fully automatic degassing device

Picking a carbon black packaging machine is not just about speed or cost. Companies must think about safety and rules. These rules help keep workers, products, and nature safe. There are two main things to look at: industry certifications and environmental laws.

Industry Certifications

Industry certifications prove a machine is safe and high quality. Trusted groups give these certificates. They check if the machine works safely and packs carbon black well. Some common certificates are CE, ISO, and GMP.

Here is a table to show what each certificate means:

Certification | What It Proves |

|---|---|

CE | Follows European safety rules |

ISO | Uses global quality steps |

GMP | Good for food and medicine |

Machines like Henll’s Full-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine often have these certificates. This makes companies feel sure about safety and quality.

Tip: Always ask to see certificates before buying. Certified machines help stop legal problems and keep workers safe.

Environmental Regulations

Carbon black dust can hurt air and soil. Governments make rules to stop pollution. Companies must follow these rules when packing and shipping carbon black. Machines with dust control and airtight seals help meet these rules.

Some important things to remember:

Machines should have dust removal systems.

Packaging must stop leaks and spills.

Companies should check local laws about waste and pollution.

Henll’s machine uses smart dust prevention. This helps companies follow the law and protect nature.

Note: Following environmental rules keeps the business safe from fines. It also shows customers the company cares about the planet.

By checking certificates and following rules, companies make good choices. They keep workers safe, protect nature, and earn trust from customers.

Making the Right Choice

Request Demos

Watching a packaging machine work helps people learn about it. Many companies show live demos or videos. In a demo, workers see the machine fill bags and control dust. They also watch how it seals each package. People can ask questions during the demo. They see if the controls are simple to use. Henll’s team gives demos for their Full-automatic Powder Bulk Bag Filling And Jumbo Bag Packaging Machine. These demos show how the machine packs carbon black and keeps things tidy.

Tip: Always watch a demo before you buy. Seeing the machine in action shows its speed, safety, and how easy it is to use.

Compare Options

All machines are a little different from each other. Companies should look at many brands and models. They can check things like automation, dust control, and filling accuracy. Maintenance is important too. Some machines are better for small jobs. Others are made for big orders. Henll’s machine has automatic degassing and fits many bag sizes. A table can help compare the main features:

Feature | Henll Machine | Other Brands |

|---|---|---|

Dust Control | ✅ | Varies |

Automation Level | High | Medium |

Bag Size Flexibility | Wide Range | Limited |

Maintenance Ease | Easy | Varies |

Note: Comparing machines side by side helps companies pick the best one for them.

Consult Experts

Experts know a lot about packaging machines. They can help pick the right model for each powder and job size. Experts share tips about new machines and common issues. Companies can talk to engineers, suppliers, or other users. Henll’s support team also answers questions and helps with details.

Ask if the machine lasts a long time.

Check if it meets safety rules.

Get tips on training and setup.

Talking to experts helps companies make smart choices and get a machine that works well for a long time.

Picking the right Carbon Black Packaging Machine needs good thinking. Companies must find machines that fit what they need. They look for things like airtightness, dust control, and automation. It is important to think about how the machine will help in the future.

Watch live demos to see how machines work.

Ask experts for help and advice.

Compare different machines to find the best one.

Making smart choices helps companies pack safely and grow strong.

FAQ

What makes Henll’s packaging machine good for carbon black?

Henll’s machine has airtight seals. It also has a dust removal system. These features keep carbon black in the bag. They help keep the air clean. Operators can use the machine easily. They can change it for different bag sizes.

Can one machine pack different bag sizes?

Yes, Henll’s machine works with many bag sizes. Operators change the settings on the control panel. This makes it easy to pack small or jumbo bags. Companies do not need to buy extra equipment.

How does the machine help keep workers safe?

The machine has dust shields and strong seals. These features lower the risk of dust in the air. Emergency stop buttons and alarms help keep everyone safe.

Is training needed to use the machine?

Operators need basic training for the controls. They also learn how to keep the machine clean. Henll’s support team gives help and guides. Most workers learn fast because the system is easy to use.