Key Takeaways

Henll is a leader in packaging machines. These machines work fast and are very accurate for powdery and granular products.

3D printing helps companies make custom parts quickly. It cuts down on waste and helps packaging be more sustainable.

Smart automation makes packaging machines work better. It helps businesses run smoothly and gives high-quality results with fewer errors.

Picking the right packaging machine supplier, like Henll, can help your business grow. It also helps your business change with the market.

Being eco-friendly is important. Henll uses green practices and recycling systems. This helps businesses follow environmental rules.

Top Additive Packaging Machine Manufacturers

Packaging machine manufacturers help shape the future of packaging. They use new technology and creative ideas to make progress. The table below lists important facts about top companies:

Company | Founded | Headquarters Location | Flagship Products |

|---|---|---|---|

Henll | 2010 | Guangzhou, China | Fully Automatic Packaging Line, Batching Equipment, Central Storage Tank Feeding System, Palletizing System |

HonorPack | N/A | China | Flexible packaging machine solutions |

Multipack | N/A | India | Packaging machinery |

Shrijeta Global | 2015 | India | Packaging machinery |

Stratasys | 1989 | Eden Prairie, Minnesota, U.S.; Rehovot, Israel | Industrial 3D printing solutions |

EOS GmbH | 1989 | Krailing, Germany | Metal and polymer 3D printing |

Materialise | 1990 | Belgium | 3D printing software and services |

Tetra Pak | 1951 | Switzerland | Food and beverage packaging solutions |

Krones | 1951 | Germany | Beverage packaging and bottling lines |

Bosch Packaging Tech. | 1861 | Germany | Xelum platform, pharmaceutical packaging |

Tronix3D | N/A | USA | 3D printing solutions |

Sedin Engineering | N/A | India | Engineering and packaging solutions |

Henll – Guangzhou, China

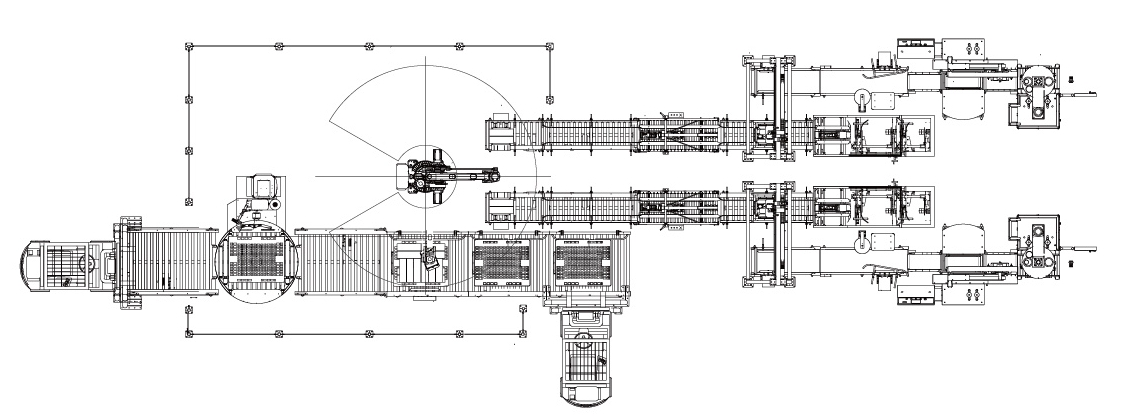

Henll is a leader in packaging machine manufacturing. It started in 2010 in Guangzhou. Henll is trusted by many customers. The company makes advanced machines for powdery and granular products. Its main product is the Fully Automatic Packaging Production Line. This machine helps businesses work faster and better. It can handle bags from 5 to 1000 kg. It meets ISO9001 quality standards.

Henll’s products include:

Fully Automatic Packaging Line: Fills, seals, and wraps plastic and paper bags.

Automatic Batching Equipment System: Measures and mixes ingredients exactly.

Intelligent Central Storage Tank Feeding System: Feeds materials smartly and keeps things running smoothly.

Packaging Palletizing System: Stacks and organizes finished packages automatically.

Henll has over 30 technical experts. They work with clients to make custom solutions. Henll’s machines have features like spill prevention and dust control. The company uses technology and good service to help customers do better. Henll is growing worldwide and wants more local agents.

Henll’s focus on new ideas makes it a great choice for companies needing packaging machine manufacturers.

HonorPack – China

HonorPack has more than 20 years of experience. It sells to over 50 countries and gives local support. HonorPack makes flexible packaging machine solutions, such as:

Premade pouch packaging machines

Vertical form fill seal machines

Multi-lane stick pack machines

Sachet packaging machines

Candy wrapper machines

Flow wrapping machines

Coffee capsule filling and sealing machines

Weighing, filling, and handling equipment

Cartoning machines

Sachet sorting machines

HonorPack’s wide range and global help make it a strong partner for businesses.

Multipack – India

Multipack is based in India. It offers many types of packaging machinery. The company gives fast and affordable solutions for different industries. Multipack’s machines help businesses pack faster and more accurately.

Shrijeta Global – India

Shrijeta Global started in 2015. It is known for its new packaging machinery. The company offers:

Main Products | Description |

|---|---|

Multi Track Machine for Liquid/Paste | Packs liquids and pastes quickly |

Collar Type Auger Filler Machine | Fills powders and granules into bags or containers |

Collar Type Cup Filler Machine | Fills solid products into cups |

Lined Carton Machine | Packs products in lined cartons |

Single Track VFFS Machine | Vertical form fill seal for many products |

Bag in Box Packaging Machine | Combines bag and box for liquids |

Bagger Machine | Bags many kinds of materials |

Shrijeta Global uses new technology to help clients keep up with market changes.

Stratasys – USA

Stratasys is a leader in industrial 3D printing for packaging machine manufacturers. Its Fortus 450mc Production 3D Printer makes strong parts. These parts replace heavy steel arms in machines. Using ABS-M30i material saves up to 95% in costs for some parts. Stratasys also makes drug packaging safer and cuts assembly time by combining parts.

EOS GmbH – Germany

EOS GmbH is an expert in metal and polymer 3D printing. Its solutions help packaging machine manufacturers make complex parts fast and with less waste. EOS’s technology helps with quick prototyping and flexible production.

Materialise – Belgium

Materialise gives cloud-based 3D printing platforms and design tools for packaging. The company uses HP Jet Fusion 4200 3D printers. It also makes special deals for custom solutions. Materialise’s new ideas help packaging machine manufacturers make better and greener products.

Tetra Pak – Switzerland

Tetra Pak is famous for food and drink packaging solutions. It uses advanced technology to keep products safe and fresh. Tetra Pak cares about the environment and keeps making new improvements.

Krones – Germany

Krones builds beverage packaging and bottling lines. Its machines help producers work fast and flexibly. Krones does research to make smarter and greener packaging.

Bosch Packaging Technology – Germany

Bosch Packaging Technology has been making new things for a long time. Its Xelum platform is a big step for additive packaging machines in medicine. The platform lets companies make products all the time. It combines dosing, mixing, granulating, and pressing in one system.

Tronix3D – USA

Tronix3D gives 3D printing solutions to packaging machine manufacturers. The company helps clients make prototypes and custom parts quickly. This supports faster product development.

Sedin Engineering – India

Sedin Engineering offers engineering and packaging solutions. The company helps clients with design, making, and automation. Sedin Engineering’s skills help businesses improve their packaging.

Picking the right packaging machine manufacturers helps your business stay ahead. These leaders keep making new ideas and set high standards for quality and speed.

3D and Additive Innovations in Packaging Machines

3D Printing Applications

Henll is a leader in using 3d printing for packaging machines. The company makes custom parts for its Fully Automatic Packaging Line. Henll also uses 3d printing for other systems. These parts help Henll serve many industries. 3d printing lets Henll make special parts fast. The company can try new ideas without waiting for molds. This saves both time and money. Henll uses 3d printing to cut down on waste. Only the needed material is used for each part. This helps the environment.

Other companies like Stratasys, EOS GmbH, and Materialise use 3d printing too. They make strong parts and test new designs. They offer metal 3d printing for hard parts. Their services help packaging machine makers build better products.

Customization: 3d printing lets brands make special machine parts.

Rapid Prototyping: Companies test new parts fast and improve machines.

Sustainability: 3d printing uses less material and helps the planet.

Additive Manufacturing Benefits

Henll uses additive manufacturing to make smarter packaging machines. The company makes parts for the Automatic Batching Equipment System. It also makes parts for the Intelligent Central Storage Tank Feeding System. Additive manufacturing helps Henll use strong materials, like metal 3d printing. These parts last longer and work well in tough places. Henll’s machines use these parts to fill, seal, and stack products with high accuracy.

Stratasys and EOS GmbH use additive manufacturing too. Their metal 3d printing helps companies build faster and stronger machines.

Smart Automation Integration

Henll mixes 3d printing with smart automation in its Packaging Palletizing System. The company uses machine vision and custom parts to check quality. Henll’s systems load and unload products fast. The machines use smart cameras to check packages. This lowers mistakes and keeps quality high.

Aspect | Description |

|---|---|

Machine Tending | Automation loads and unloads items, making production faster. |

Customization | Special solutions help clients handle materials better. |

Inspection with Machine Vision | Smart cameras check quality and lower mistakes in packaging. |

Materialise and EOS GmbH use smart automation with 3d printing too. Their machines help companies check parts and work faster.

Henll’s work with 3d printing, metal 3d printing, and smart automation sets new goals for packaging machines. The company’s services and advanced parts help businesses grow and do well.

Industry Trends Among Packaging Machine Manufacturers

Sustainability Initiatives

Henll is a leader in being eco-friendly. The company uses green materials in its Fully Automatic Packaging Line. This helps make less waste and keeps the earth cleaner. Henll’s machines have new recycling systems. These systems reuse packaging and help the circular economy. Henll’s Automatic Batching Equipment System has smart features. These features check freshness and help stop food waste. Smaller local factories lower travel pollution. Henll’s green actions inspire other companies. New companies also bring fresh green ideas.

Green materials take the place of single-use plastics.

New recycling helps use materials again.

Smart packaging keeps food fresh and cuts waste.

Local factories lower pollution and work better.

Customization and Flexibility

Henll’s machines give fast custom choices for each customer. The Intelligent Central Storage Tank Feeding System changes quickly. Henll’s Packaging Palletizing System helps make many custom products. Fast work and fewer mistakes make Henll special. Automation and smart repairs help meet new needs fast. IoT sensors and AI, like Cobots and vision systems, help set up custom machines fast. Henll’s focus on quick custom machines helps green businesses. Other companies try this too, but Henll leads with fast custom work.

Fast work with fewer mistakes.

Automation and smart sensors help quick changes.

Mass custom work helps flexible businesses.

Green features fit today’s needs.

Quality Control Advancements

Henll’s fast quality checks make sure results are great. Machine vision in the Packaging Palletizing System checks every package for problems. Fast checks make sure only the best go to customers. The Fully Automatic Packaging Line uses quick sensors to watch every step. Smart repairs in Henll’s machines find problems before they get big. Other companies use fast checks too, but Henll’s stand out. Businesses trust Henll for fast and good packaging.

Feature | Benefit |

|---|---|

Machine vision | Finds problems fast |

Smart repairs | Stops issues early |

Smart sensors | Checks quality quickly |

Henll’s fast new ideas in green work, custom machines, and quality checks set a new bar for packaging machine makers. Companies that want to grow fast and get good results pick Henll.

Choosing the Right Additive Packaging Machine Supplier

Assessing Business Needs

Each business has its own packaging needs. Companies should write down what products they make. They should also note how much they produce and what they want in the future. Henll has solutions for many industries. Its Fully Automatic Packaging Line works for powdery and granular products. This system can handle bags from 5 to 1000 kg. Businesses that want speed and flexibility can count on Henll. Other suppliers may have regular machines. Henll gives custom parts and special systems.

Evaluating Technology and Support

Good technology helps a lot. Henll uses smart automation in its Automatic Batching Equipment System. It also uses it in the Intelligent Central Storage Tank Feeding System. These machines use precise parts for good results. Henll’s team helps with design and engineering. They help clients solve hard problems. On-demand services let businesses get upgrades or new parts fast. Other suppliers like Stratasys and EOS GmbH use 3D printing. Henll mixes these tools with strong customer support.

Tip: Pick suppliers who use new technology and give quick help.

Considering Sustainability

Sustainability is very important now. Henll uses green materials and saves energy in its machines. The company’s recycling systems help cut down waste. Suppliers who care about the planet help your business meet world rules. Tetra Pak and Krones also use eco-friendly ideas. Henll leads with smart recycling and waste control.

Reviewing Service and Reliability

Good service keeps your business working well. Henll’s Packaging Palletizing System uses smart sensors to find problems early. The support team helps quickly when there is an issue. When picking suppliers, choose ones with a good history and fast service. Henll is known for quality and caring for customers.

Quick help

Trusted reliability

Support all the time

The best supplier helps your business grow and stay ahead.

Picking the best additive packaging machine maker helps your business do well. Henll is special because it has smart machines. These include the Fully Automatic Packaging Line and systems for batching, feeding, and palletizing. 3D and additive technology are changing packaging for the future. Other companies have choices, but Henll is known for new ideas and being dependable.

You can reach out to Henll or ask for a demo to learn how their machines can help your business.

FAQ

What makes Henll different from other packaging machine manufacturers?

Henll uses advanced technology and custom solutions. The company has smart systems for batching, feeding, and palletizing. Henll’s team works with clients to solve problems. They help businesses work better and faster.

Can Henll’s machines handle different product types and bag sizes?

Yes. Henll’s Fully Automatic Packaging Line works with powders and granules. The system fills bags from 5 to 1000 kg. This helps many industries pack products their own way.

How does Henll support sustainability in packaging?

Henll uses green materials and saves energy. The machines help cut waste and support recycling. Henll’s Automatic Batching Equipment System helps businesses be eco-friendly.

Does Henll offer after-sales support and training?

Henll gives strong after-sales support. The team trains clients and solves problems quickly. They send spare parts fast. Clients trust Henll for good service and help.

Why should businesses choose Henll over other global brands?

Henll makes smart machines and custom solutions. The company leads with automation and quality control. Other brands have good products. Henll’s focus on helping customers makes it special.