Full-automatic vertical vacuum sealer

Full-automatic vertical vacuum sealer Features

1.By enclosing the material with a container, and vacuuming the inside of the container, it is possible to evenly remove the air from the material, ensuring that all the materials inside the bulk bag are uniformly deaerated.

2.The material extraction effect is good, and the material can be stacked and placed without tilting.

3.By enclosing the material with a container, and vacuuming the inside of the container, it is possible to evenly remove the air from the material, ensuring that all the materials inside the bulk bag are uniformly deaerated.

4.It adopts a lifting door opening device, which has a small footprint and can completely replace the external vacuum sealer.

5.It automatically clamps the bag mouth and feeds the bag to avoid manual operation inside the box, which is convenient and safe to operate.

Full-automatic vertical vacuum sealer Specification

| project | Classification | |

| Heat seal width | Maximum1500*1500*1500mm | |

| Vaximum negative pressure value | Can reach -50KPA | |

| Heat sealing function | Single sided type | Double-faced |

| Number of sealing strips | Single channel heat sealing type | Double channel heat seal type |

| material quality | Stainless Steel 304L/316L | Body part sprayed plastic steel type |

| explosion-proof | Explosion proof type | Non-explosion-proof type |

| speed | 8 packages/hour | |

Full-automatic vertical vacuum sealerComparison before and after packaging

1.Berore vacuuming, the gas content of the material is significantly reduced, resulting in a denser and more compact state. This increases the bulk density of the material, making it less fluffy. As a result, during subsequent stacking and palletizing processes, the bags are more stable and less prone to toppling over. Vacuuming helps to eliminate excess air from the bags, ensuring a more secure and stable stacking arrangement. This improves overall efficiency in handling, reduces the risk of bag collapse, and optimizes the use of storage space.

2.After vacuuming, the material's bulk density significantly increases, resulting in a more compact packaging. This leads to a smaller footprint during subsequent stacking and palletizing processes. As a result, the utilization of space is optimized, making logistics loading more convenient. Moreover, the reduced gas content in the bags reduces the risk of bags toppling over and other related issues, such as bag collapse. Overall, vacuuming improves the efficiency of material handling, reduces the occurrence of bag-related incidents, and facilitates smoother transportation and logistics operations.

Full-automatic vertical vacuum sealer Range Of Configuration

Chemical powder and granule industry: such as fertilizers, rubber powder, pigments, dyes, coatings, catalysts, cosmetic ingredients, etc.

Food powder and granule industry: such as flour, starch, powdered sugar, coffee powder, seasoning powder, pet food, etc.

Pharmaceutical powder and granule industry: such as traditional Chinese medicine powders, Western medicine powders, active pharmaceutical ingredients, etc.

Metallurgical powder and granule industry: such as metal powders, alloy powders, etc.

New materials industry: such as nanomaterials, graphene powder, polymer material powders, composite material powders, metal oxide powders, etc.

New energy industry: lithium battery material powders, such as cathode materials (such as lithium iron phosphate, lithium cobalt oxide, etc.) and anode materials (such as graphite, silicon, etc.), solar cell material powders, such as silicon powder, germanium powder, used for manufacturing solar cells, fuel cell material powders, such as catalyst powders (such as platinum, palladium, etc.),

Super capacitor material powders, such as activated carbon powder, ruthenium oxide powder, etc.

Full-automatic vertical vacuum sealer Description

1.Intelligent control of vacuum level helps to reduce the gas content in the bulk bag, ensuring a double-sided and secure seal and bag shape through a reliable heat sealing mechanism.

2.Improving the bulk density of the material to meet the required standards facilitates storage and transportation.

3.During the operation, there is no loss or waste of material, and it ensures a clean working environment without powder spillage.

4.Full-automatic vertical vacuum sealer reduces complex procedures and significantly reduces the manual labor intensity.

5.Full-automatic vertical vacuum sealer is compatible with integration with upstream and downstream processes, allowing for easy implementation of automated management for the entire packaging line (including metering, filling, sealing, wrapping, coding, palletizing, etc.).

6.Full-automatic vertical vacuum sealer effectively improves production efficiency, reduces manual labor, and significantly lowers operating costs

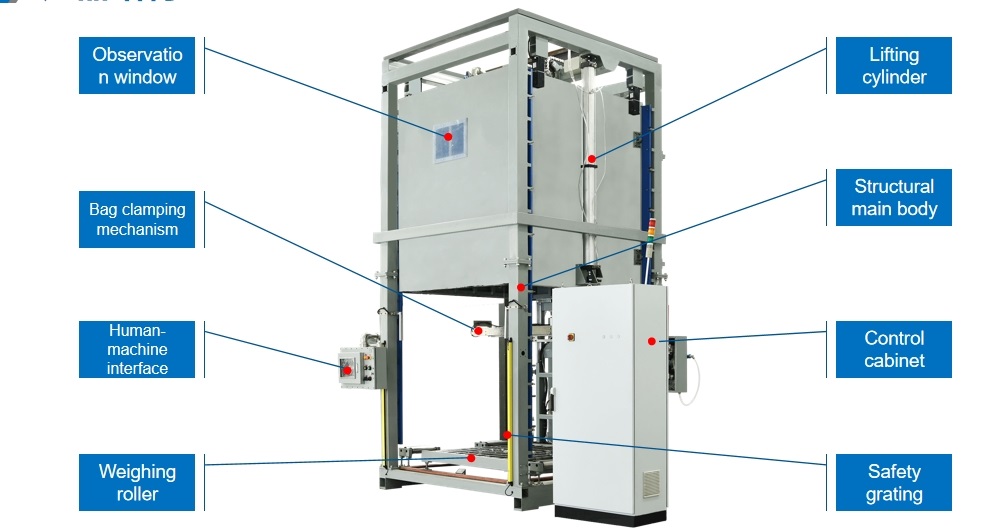

Full-automatic vertical vacuum sealer Construction

1.Observation window:

The design incorporates a transparent observation window at the center, enabling real-time monitoring of the vacuuming process inside the container.

2.Lifting cylinder:

Imported large-sized cylinders are known for their long service life.

3.Bag clamping mechanism:By lengthening and upgrading the bag-clamping mechanism, we ensure that there is no bag toppling, no material leakage, and no foreign object dropping.

4.Structural main body:

The main body is made of carbon steel with a powder coating and can be customized to support 304L/316L stainless steel material.

5.Human-machine interface:

The intelligent human-machine interaction interface is simple and convenient to operate.

6.Control cabinet:

Professional industrial control cabine

7.Weighing roller:

High-precision weighing sensor, automatic weighing to ensure packaging accuracy.

8.Safety grating:

Highly sensitive opposing safety grating ensures safety in the production process.