Positive electrode materials are the key raw materials for lithium batteries, affecting the cycling life, energy density and safety performance of lithium batteries, directly determining the performance of the final product. Among them, in the field of power batteries, lithium iron phosphate cathode materials have higher safety performance, longer cycle life, better high temperature performance and lower raw material costs compared to nickel-cobalt-manganese-lithium ternary materials (NCM), nickel-cobalt-aluminum-lithium ternary materials (NCA), lithium cobalt oxide and lithium manganese oxide, and have very good application prospects.

In response to the above pain points, Guangzhou Heng'er Electronic Equipment Co., Ltd., which has unique technology and engineering experience, has very practical solutions in many practical operation cases of lithium iron phosphate.

To tackle the issue of the lithium iron phosphate material becoming sticky after absorbing moisture, Guangzhou Herl has applied PTFE spray in the material channel; installed air cushion/vibration devices in the silo to aid flow; and used airbag-style bag clamps to ensure sealing, significantly reducing contact between the material and air—a triple solution to the problem.

Addressing the issue of high material costs and packaging machine inaccuracy leading to material waste, Guangzhou Herl has developed targeted improvements to the packaging machine structure, utilizing a high-precision weighing system to ensure a packaging accuracy within ±300g. It can also be equipped with an automatic re-weighing system for adding or subtracting material, greatly reducing manual operations.

For the problem of materials having a high gas content and difficulty in expelling air from the packaging bags, Guangzhou Herl uses an internal vacuum extraction method that completely removes the air from the material. This method utilizes the principle of material sedimentation and does not directly extract the air from inside the packaging, thus avoiding material loss—a clever solution to this challenge.

In terms of the large space occupation of packaged products, Guangzhou Herl employs a box-type internal vacuum extraction method, allowing the material to be fully degassed, significantly increasing material density, thereby reducing packaging volume. This enables stackable storage, saving space for product placement.

Regarding issues such as bag inversion, breakage, and damage during the transportation of packaged products, Guangzhou Herl uses a box-type internal vacuum sealing machine to completely degas the material, ensuring stackability during ton-package transportation, preventing swelling of the bags, and avoiding subsequent breakage and damage.

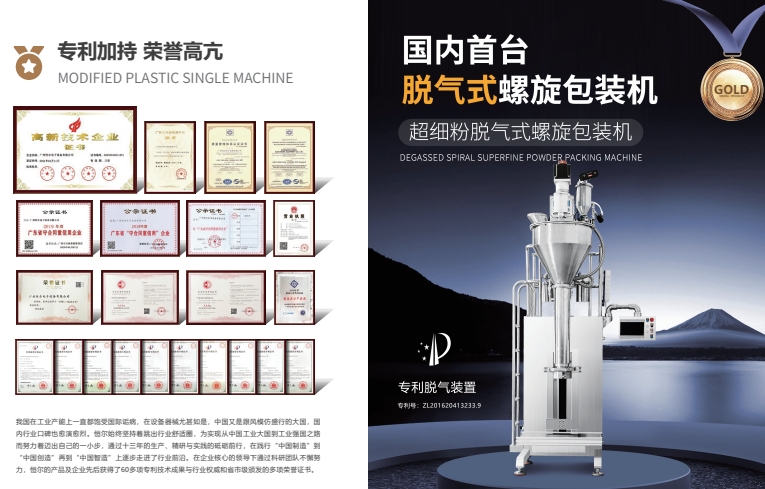

Guangzhou Henll Electronic Equipment Co., Ltd. was established in 2010 and is a high-tech enterprise that integrates research and development, production, sales, and service. The company's factory covers an area of 18,000 square meters and is located in the Panyu District of Guangzhou. Its main business includes the manufacturing of ultra-fine powder pneumatic conveying systems, specialized filling, measuring, and stacking equipment for ultra-fine powders, industrial automatic control system devices, oil volume control and measuring equipment for the feed industry, manufacturing of 5-50KG large bag automatic packaging machines, as well as automatic packaging machines for ultra-fine powder ton packages, and fully automatic vacuum sealing machines for ultra-fine powders.

With its professional level and mature technology in the field of automation, Guangzhou Herl has rapidly emerged in the fields of packaging and automated production lines. Relying on technological development and continuously providing customers with satisfactory high-tech products is the company's unwavering pursuit. After years of development, the company has successfully independently developed products such as fully automatic oil spray detection equipment, automatic bag loading machines, and automated packaging lines, and has obtained several patent technologies including "a type of degassing cylinder and packaging machine" and "an oily feed production system and oil spray volume control system." At the same time, by fully introducing and absorbing foreign advanced technologies, the company has successfully developed specialized products such as the ultra-fine powder dedicated degassing packaging scale series and automatic quantitative packaging scales. The company has received widespread recognition from lithium iron phosphate users for its first-class product quality and exquisite technical service.