How Snack Packing Machines Work and What They Do

A snack packing machine automates the process of weighing, filling, and sealing snacks into bags or pouches. Today, nearly 74% of snack producers worldwide rely on automated machines to boost efficiency and reduce labor costs. These machines can double packaging speed compared to manual methods, helping companies meet rising demand. The market for snack packing machines continues to grow, driven by advanced technology and a global appetite for packaged snacks.

Key Takeaways

Snack packing machines automate weighing, filling, sealing, and labeling to package snacks quickly and safely.

Different machine types suit various snacks and packaging styles, offering speed, accuracy, and flexibility.

These machines keep snacks fresh longer by using airtight seals, vacuum sealing, and resealable zippers.

Automation boosts productivity, reduces labor costs, and minimizes waste while ensuring consistent quality.

User-friendly designs and adjustable settings let operators handle many snack types and packaging formats easily.

Snack Packing Machine Types

Snack packing machines come in several types, each designed for different snacks and packaging needs. The table below gives a quick overview of the main types, their best uses, and key features:

Snack Packing Machine Type | Description | Best For | Key Advantages | Drawbacks |

|---|---|---|---|---|

Vertical Form Fill Seal (VFFS) | Forms bags from film, fills with snacks, seals, and cuts vertically. | Chips, nuts, cereals, snacks in bags | High speed, versatile, cost-effective | Limited to flexible bag packaging |

Horizontal Form Fill Seal (HFFS) | Forms and fills pouches horizontally, often with zippers or gussets. | Candy bars, bakery items, solid snacks | High accuracy, handles complex packaging | Larger footprint, higher cost |

Pre-Made Pouch Machines | Fills and seals pre-made pouches, supports many pouch types. | Chips, granola, trail mix, pet food | Flexible, resealable, quick changeovers | Slower than VFFS, higher pouch cost |

Multihead Weighers | Weighs snacks precisely before dispensing into packaging. | Nuts, pretzels, products sold by weight | High accuracy, speed, reduces waste | Only for weighing and dispensing |

Vertical Form Fill Seal

Vertical Form Fill Seal (VFFS) machines create bags from a roll of film, fill them with snacks, and seal them in a vertical process. These machines work well for snacks like potato chips, nuts, and cereals. VFFS machines can package snacks in pillow bags, gusseted bags, or stickpacks. They support both single-serve and family-sized packs. Many snack producers choose VFFS machines because they offer high speed and can handle a wide range of snack products. The airtight sealing helps keep snacks fresh and extends shelf life.

Tip: VFFS machines can run at speeds from 40 to 1000 bags per minute, making them ideal for high-volume snack production.

Horizontal Form Fill Seal

Horizontal Form Fill Seal (HFFS) machines form, fill, and seal pouches as they move horizontally. These machines often package solid snacks like candy bars, bakery products, and granola bars. HFFS machines can create three-sided seal pouches, stand-up pouches with zippers, and other complex packaging styles. They offer high accuracy and can handle products that need careful placement. HFFS machines usually have a larger footprint but provide faster speeds and more packaging options than VFFS machines.

Pre-Made Pouch Machines

Pre-made pouch machines fill and seal ready-made pouches. They handle many pouch types, such as stand-up, zipper, flat, and shaped pouches. These machines work with snacks like chips, trail mixes, and pet foods. Pre-made pouch machines allow quick changeovers between pouch sizes and types, which helps reduce downtime. They also offer features like gas flushing and resealable closures to keep snacks fresh. Their flexibility supports brand differentiation and efficient production.

Pre-made pouch machines can fill liquids, powders, granules, and solids.

They support high-speed operation and reduce setup times.

Multihead Weighers

Multihead weighers use several weighing heads to measure snacks with great accuracy. Each head weighs a small amount, and the machine combines these to reach the exact target weight. This method works well for snacks sold by weight, such as nuts or pretzels. Multihead weighers use advanced technology to keep speed and precision high. They help reduce product giveaway and waste, and they save time by removing the need for manual checks. Real-time monitoring allows quick adjustments, improving both accuracy and efficiency.

Multihead weighers help snack producers meet strict quality standards and boost productivity.

How Snack Packing Machines Work

Snack packing machines follow a clear, step-by-step process to package snacks quickly and safely. Each stage uses advanced technology to keep snacks fresh and production lines running smoothly.

Feeding and Dispensing

The process begins with feeding and dispensing. A metering hopper stores the bulk snacks and releases even portions onto a vibratory feeder. This feeder gently moves the snacks forward, making sure the flow stays steady and accurate. The system prevents jams and keeps the line moving. Sensors and conveyors help arrange snacks of different shapes and sizes, so each piece enters the next stage in the right position. This method increased production capacity by thousands of pounds per day for some manufacturers.

Tip: A steady snack flow helps avoid waste and keeps the machine running at top speed.

Weighing and Filling

Next, the machine measures and fills the snacks into packaging. Modern snack packing machines use several technologies for this step:

Auger fillers work well for powders, giving consistent doses.

Counting systems ensure the right number of snacks go into each pack.

Multi-lane weighing belts handle many snack types at once.

Advanced weighing scales and dosing controls reduce product giveaway.

The machine can adjust for different snack sizes and weights. Stainless steel parts and easy-to-use screens make cleaning and operation simple. These features help keep the process hygienic and efficient.

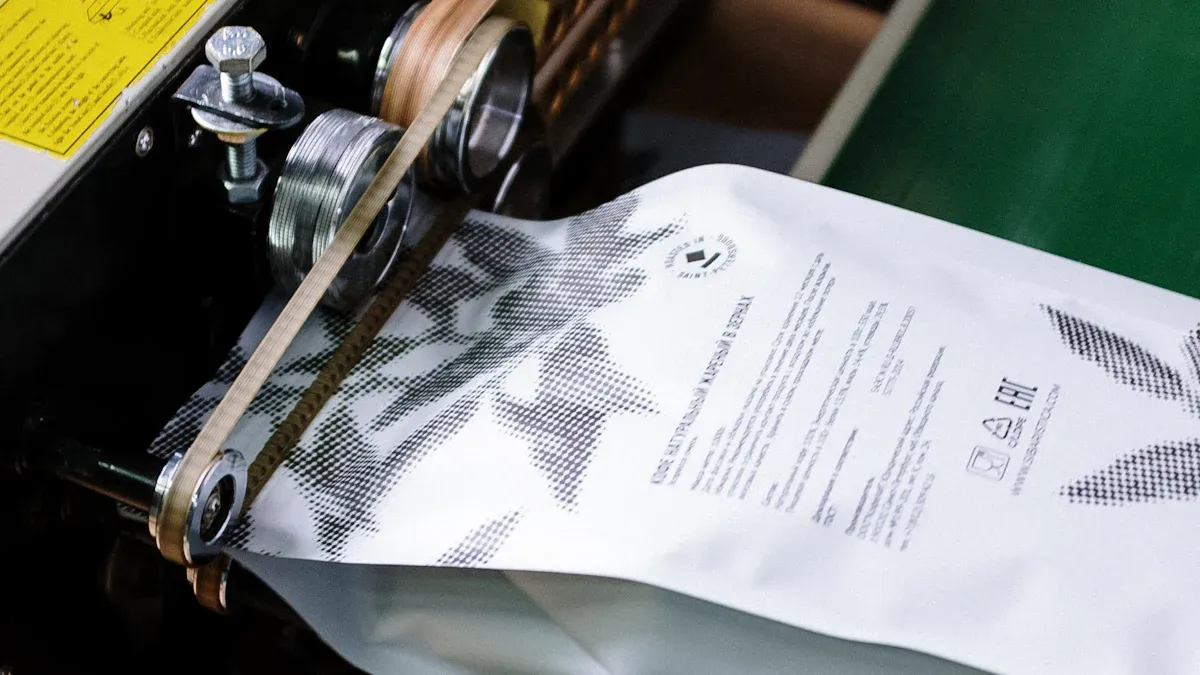

Sealing and Packaging

After filling, the machine seals the snacks inside their packaging. Sealing methods include heat sealing, vacuum sealing, and resealable zippers. Each method protects the snacks in a different way:

Heat sealing creates an airtight barrier that blocks air, moisture, and germs.

Vacuum sealing removes air, which slows spoilage and keeps snacks fresh longer.

Zipper seals let people open and close the bag many times, keeping snacks fresh between uses.

Vacuum sealing works best for snacks that spoil quickly or need long storage. Heat sealing is common for chips and nuts. Zipper seals are popular for snacks eaten over several days.

Sealing keeps snacks safe from air and moisture, which helps them last longer and taste better.

Labeling and Additional Functions

The final step adds labels and other features. Snack packing machines often include:

Labeling systems for brand names, flavors, and nutrition facts.

Coders for dates and tracking.

Barcode and QR code printing for inventory and marketing.

Some machines use cameras and sensors to check labels and reject any errors. These features help snack makers meet safety rules and make their products easy to track and sell.

Labeling systems can print directly on the package or apply pre-printed labels, making the process fast and accurate.

Snack packing machines use automation, robotics, and smart controls to boost speed, reduce mistakes, and keep snacks clean. Adjustable parts let companies package many snack types and sizes with one machine. This flexibility helps snack makers meet changing market needs.

Snack Packing Machine Features

Speed and Efficiency

Snack Packing Machine models deliver impressive speed and efficiency. Leading machines such as the Wolf-Packing Platinum VFFS and tna ropac 5 Case Packer can reach up to 300 bags per minute.

Machine Model | Speed (bags per minute) |

|---|---|

Wolf-Packing Platinum VFFS | Up to 300 |

tna ropac 5 Case Packer | Up to 300 |

Automation streamlines operations and reduces labor costs. Manufacturers report up to a 30% reduction in packing time after upgrading to automated weigh-filling technology. Automation also boosts overall packing efficiency by 20-40%, improving speed, accuracy, and reducing waste. Smart sensors and robotics allow real-time monitoring and precise portion control, which enhances product quality.

Automated Snack Packing Machines help companies meet high demand while maintaining consistent output.

Flexibility

Snack Packing Machines handle many snack types and packaging formats. Specialized machines exist for granules, chips, corn snacks, and pillow bread. Operators can load pre-made bags, fill them with products, and seal them, which allows flexibility in packaging styles. Customizable parameters include bag style, size, fill weight, output speed, and packaging complexity. Toolless changeover capabilities let operators switch between pillow bags, sachets, and stand-up pouches quickly.

Machines suit low-skilled labor and offer user-friendly controls.

Flexibility in packaging options helps manufacturers adapt to changing consumer trends.

Product Protection

Snack Packing Machines protect snacks from contamination and damage. They use protective packaging materials like air-filled cushioning and foam inserts to absorb shocks. Advanced weighing systems ensure accurate portion control, preventing damage from uneven distribution. Sealing methods such as heat sealing and vacuum sealing create airtight packaging that blocks moisture and oxygen. Tamper-evident features like tear strips and shrink bands provide visible evidence of tampering.

Automated processes reduce human error and physical damage.

Metal detectors and controlled sealed environments help maintain product freshness and safety.

Ease of Use

Snack Packing Machines feature designs that make operation and maintenance simple. Machines use food-grade stainless steel, which resists corrosion and supports easy cleaning. Many models include automated cleaning functions and Clean-in-Place technology. Operators benefit from comprehensive training and support services. Sensor systems detect malfunctions, and timely action on alerts keeps machines running smoothly.

User-friendly interfaces and toolless changeovers minimize downtime.

Regular maintenance, including daily cleaning and scheduled inspections, ensures reliability.

Automated bagging machines minimize direct human contact, reducing contamination risks and improving hygiene compared to manual packaging.

Performance and Customization

Snack Types and Materials

Snack producers select machines based on the physical properties of their products. Liquids need liquid fillers, while solid foods require form-fill-seal or vacuum sealers. Machine choice impacts sealing quality and operational efficiency. Packaging materials play a key role in protecting snacks. Metallized films and multilayer designs block moisture and oxygen, keeping snacks fresh. Machines must control sealing temperature precisely to maintain barrier integrity. Poor machine quality can cause sealing failures and damage packaging. Bag style and size also affect performance. Adjustable settings help machines handle pillow, gusseted, and linked bags without losing speed or product integrity.

Factor | Impact on Machine Performance |

|---|---|

Machines must work with plastic film, aluminum foil, or laminated films to ensure proper sealing. Poor-quality machines may fail to handle laminated films, affecting sealing quality. | |

Bag Style and Size | Machines need to adjust for different bag styles and sizes, maintaining efficiency and product integrity. |

Temperature Control | Flexible temperature control systems are essential for sealing various packaging materials, impacting sealing quality and reliability. |

Note: Choosing the right machine and material combination helps maintain snack quality and boosts production efficiency.

Machine Settings

Operators adjust machine settings to optimize packaging for each snack product. They synchronize line steps, including product infeed, weighers, and sealing, to prevent pile-ups. Equipment calibration for different packaging materials ensures package integrity. Product handling features like soft-drop weighers and anti-static conveyors protect fragile snacks. User-friendly interfaces allow quick program changes and fast changeovers. Real-time performance tracking monitors run rates, downtime, and seal failures. Automated case packers adjust bag counts per row and rows per case using HMI presets. Integration with multihead weighers and vertical form-fill-seal machines provides precise portion control for irregular products. Quality control checkpoints check seal integrity, fill weight, and product appearance.

Synchronize line steps for smooth transitions.

Calibrate equipment for packaging materials.

Control product handling features for fragile snacks.

Use user-friendly interfaces for quick changes.

Track performance in real time.

Adjust case packer settings for different pack patterns.

Integrate weighers for precise portion control.

Add quality control checkpoints for consistent results.

Custom Options

Manufacturers offer many customization options to meet unique production needs. Machines can print custom logos, graphics, and packaging designs. Bagging capabilities support classic center sealing and custom shapes. Machines work with various packaging materials, including plastic film, paper film, and single-layer PE film. Operators can select different bag sizes and sealing styles. Custom design and consultation services help tailor machines to specific requirements. Machines offer scalable and upgradable features to grow with production demands. Compatibility with eco-friendly, recyclable, and biodegradable materials supports sustainability goals.

Custom logos and graphics for branding.

Versatile bagging for different bag types.

Support for various packaging materials.

Adjustable bag sizes and sealing styles.

Custom design services for unique needs.

Scalability and upgradability.

Eco-friendly material compatibility.

Automated machines help companies use recyclable and biodegradable packaging. Advanced sealing jaws and digital printing reduce material use and support traceability. These features help snack producers meet environmental standards and consumer expectations.

Snack packing machines operate by automating feeding, weighing, filling, sealing, and labeling. They deliver major benefits for snack producers:

Enhanced product quality and safety through precise, hygienic packaging.

Extended shelf life with airtight seals and controlled atmosphere packaging.

Improved productivity and efficiency from high-speed automation.

Cost savings due to reduced labor and material waste.

Flexibility to handle many snack types and packaging formats.

Feature | Benefit |

|---|---|

Reduces damage and contamination | |

Adapts to different products | |

Ease of use | Supports smooth workflows |

Snack producers who invest in these machines gain reliable, efficient, and flexible packaging solutions that help meet market demand and protect their brand reputation.

FAQ

What snacks can a snack packing machine handle?

Snack packing machines work with chips, nuts, candy, granola bars, and even pet treats. Some machines can also pack powders or liquids. The right machine depends on the snack’s shape, size, and texture.

How does a snack packing machine keep snacks fresh?

The machine seals snacks in airtight bags. This seal blocks air and moisture. Some machines use vacuum sealing or gas flushing. These methods help snacks stay crisp and safe for longer periods.

Can one machine pack different snack sizes?

Yes. Many machines have adjustable settings. Operators can change bag size, fill weight, and sealing style. This flexibility lets companies pack single-serve and family-size snacks on the same machine.

How do snack packing machines improve hygiene?

Snack packing machines use stainless steel parts and automated cleaning systems. These features reduce human contact. They help keep snacks clean and lower the risk of contamination.

Are snack packing machines hard to use?

Most modern machines have touch screens and simple controls. Operators receive training and support. Many models offer quick changeovers and easy maintenance, making them user-friendly for most workers.