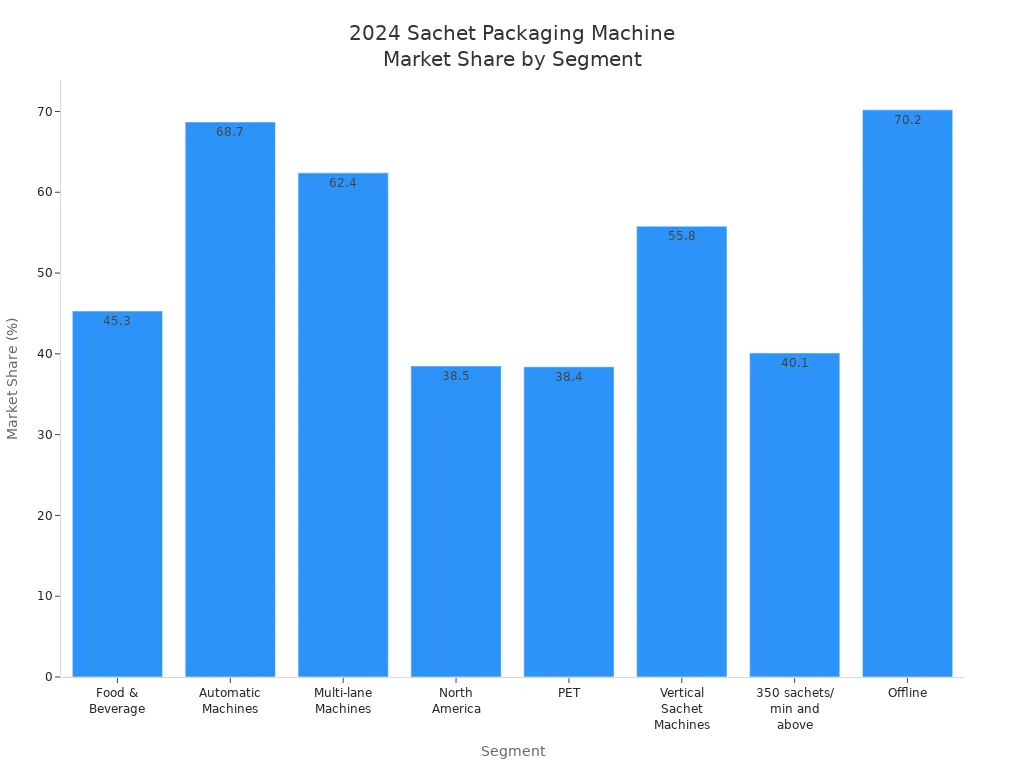

The best sachet packaging machine for food, pharmaceutical, and liquid products works fast. It fills each sachet with the right amount and seals it tightly. Top companies like Landpack, Turpack, and GREAT PACK make machines for powders and liquids. These machines can be used by small or big businesses. Picking the right machine helps make more products quickly. It also makes sure each sachet is filled correctly and meets safety rules. In 2024, the global market was worth $585.48 million. This happened because more people want automation, better speed, and to follow rules.

Key Takeaways

Sachet packaging machines fill and seal small packets fast. They work for powders, liquids, and granules. These machines help companies make more products. They also help reduce waste.

Different machines fit different products. Vertical machines are good for powders and granules. Horizontal machines are better for liquids. Multi-lane machines make things faster for big orders.

Picking the right machine depends on your product. It also depends on how much you make and your budget. You must follow safety rules to keep quality and meet laws.

Automation and good care make machines faster and more accurate. They help machines last longer. They also lower mistakes and save on labor costs.

Buying a flexible and easy-to-use machine saves money over time. It helps make more products and cuts waste. It also helps your business grow.

Overview

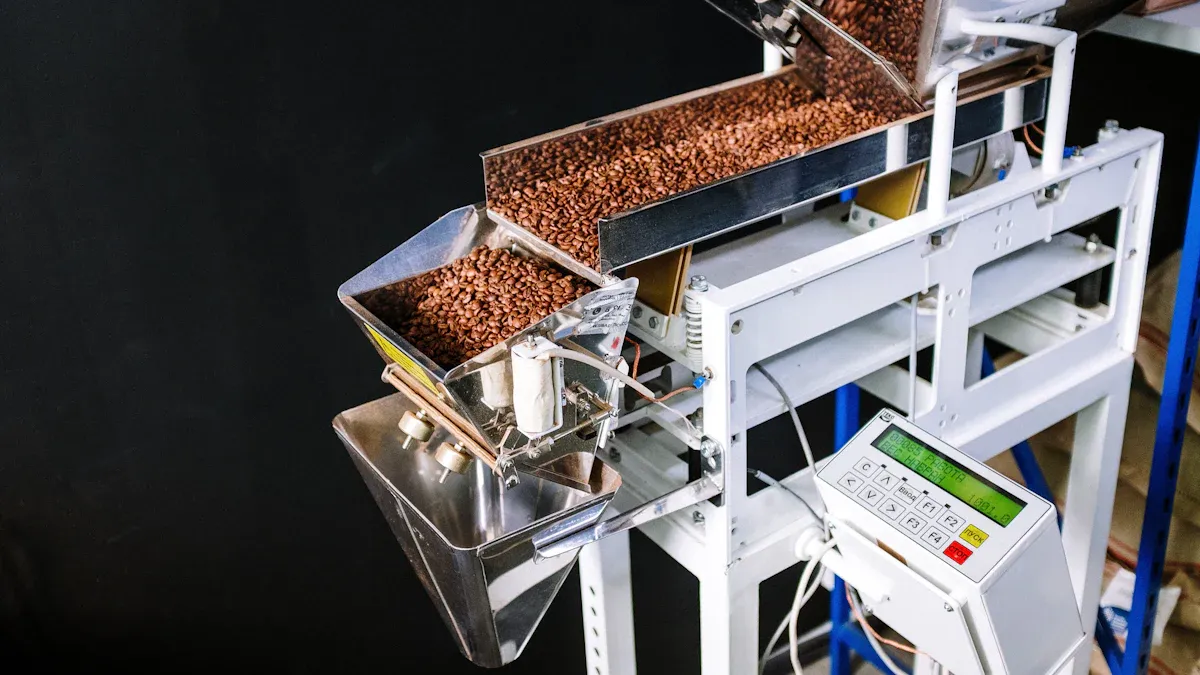

What Is a Sachet Packaging Machine

A sachet packaging machine makes small packets called sachets. It does this by forming, filling, sealing, and cutting them. These machines can work with powders, liquids, granules, and pasty things. People use them to pack coffee, spices, sauces, and medicines. The machine pulls film and shapes it into sachets. It puts the right amount of product inside each one. Then, it seals and cuts the sachets so they all look the same. Some machines, like the SLF3-50, use auger filling for powders. They use piston pumps for liquids. Newer machines have alarms to help stop waste. They use servo motors to move the film just right. Coding features help track each sachet. Many machines let you pick special shapes or add tear notches. Some can fill many sachets at once to work faster.

Tip: Multi-lane sachet packaging machines help companies make more sachets quickly. They also save on film, which is good for big jobs.

Common types of sachet packaging machines are:

Horizontal Form Fill Seal (HFFS) machines work fast with liquids.

Vertical Form Fill Seal (VFFS) machines can do many jobs.

Colloid type machines are for thick liquids.

Multi-track machines make lots of sachets at once.

Single-lane stickpack machines are for small batches and special shapes.

Main Applications

Sachet packaging machines are used in many businesses. Food and drink companies use them for dressings, oils, sauces, and condiments. Dairy companies use vertical form fill seal machines for liquids and pasty foods. Pharmaceutical companies pack single-dose medicines and powders with special machines. Cosmetics companies use them for soaps, gels, and lotions. Nutraceutical brands pack powders and granules. Pet care companies use fast machines for both liquid and solid pet products.

Industry | Main Products Packaged | Machine Types / Features |

|---|---|---|

Dressings, oils, sauces, condiments | High-speed, multi-lane, stickpack, pouch machines | |

Dairy | Liquids, pasty products | Vertical form fill seal machines |

Pharmaceuticals | Medicines, powders | Stickpack, sachet, INVpack machines |

Cosmetics | Soaps, gels, lotions | High precision, ultraclean, custom-shaped sachets |

Nutraceuticals | Powders, granules | Machines for solids, granules, powders |

Pet Care | Liquid and solid products | High-speed, precision sachet packaging machines |

Manufacturers like sachet packaging because it is small and easy to carry. It stops leaks and is handy for one-time use. This makes it popular in many industries.

Types

Powder Sachet Packaging Machine

Powder sachet packaging machines pack things like coffee and spices. They use auger fillers to handle powders that are dusty or sticky. These machines have sealing systems to stop leaks and dust. Some models let you change filling heads for powders or liquids.

Key features of powder sachet packaging machines:

Auger filling gives the right amount of powder.

Sealing keeps powder from leaking out.

Multi-lane machines work fast for big jobs.

Designs fit many sachet sizes and shapes.

Note: Powder sachets hold small amounts for one use. Stick packs are longer and can carry more, so they are good for granules.

Liquid Sachet Packaging Machine

Liquid sachet packaging machines fill and seal small liquid packs. They work with sauces, shampoos, and oils. These machines use special filling heads and strong seals to stop leaks. Automation helps with sensors and control panels for speed and accuracy.

Specification Aspect | Details / Features |

|---|---|

Filling Accuracy | Advanced filling heads give high accuracy |

Speed | Up to 70 cuts each minute, often more than 10 lines |

Automation | PLC control and real-time checks |

Sealing | Temperature seals keep sachets leak-proof |

Compliance | Follows GMP and safety rules |

Modern liquid sachet machines cut waste and make sure each sachet has the right amount.

VFFS and Rotary Machines

VFFS and rotary machines are main types of sachet machines. VFFS machines pull film down to make a tube, fill it, and seal it. They work for powders, granules, and liquids. Rotary machines feed film sideways and use a spinning system to fill and seal sachets. This makes them good for fast and tricky packaging.

Feature | VFFS Machine | Rotary Machine |

|---|---|---|

Film Feeding | Vertical | Horizontal |

Bag Formation | Tube, sealed top and bottom | Pouch, sealed sides and ends |

Speed | Up to 400 units per minute | |

Bag Design | Simple | Complex |

Cost | Lower | Higher |

VFFS machines fit most products and are small in size. Rotary machines work faster and offer more choices for tough jobs.

Top Machines

For Food Products

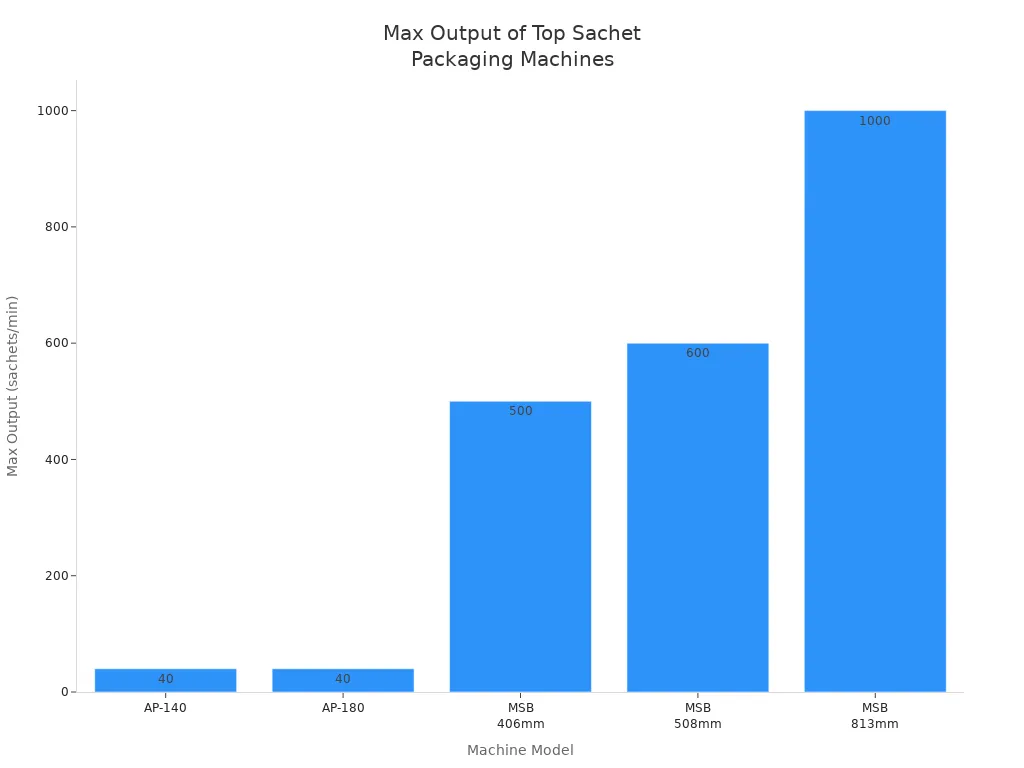

Food makers use strong sachet packaging machines for good quality and speed. Popular models like AP-140 and AP-180 Auto Pouch Baggers have parts you can change. They work well for small and medium jobs. Multilane Sachet Baggers such as MSB 406mm, MSB 508mm, and MSB 813mm make lots of sachets fast. You can pick different fillers for these machines. They are great for packing instant coffee, spices, sauces, and sweeteners in big amounts.

Machine Type | Model | Max Output (sachets/min) | Max Sachet Width | Max Sachet Length | Key Features & Suitability |

|---|---|---|---|---|---|

Auto Pouch Bagger | AP-140 | Up to 40 | 4.5 inches | 7.5 inches | Modular VFFS, reliable for small to mid-sized production, handles powders, liquids, semi-solids, low downtime |

Auto Pouch Bagger | AP-180 | Up to 40 | 8.5 inches | 11.5 inches | Robust construction, versatile, smooth operation, minimal maintenance |

Multilane Sachet Bagger | MSB 406mm | Up to 500 | 4 inches | 12 inches | Multi-lane (up to 10 lanes), high-speed, customizable fillers, suitable for powders, liquids, granules |

Multilane Sachet Bagger | MSB 508mm | Up to 600 | 5 inches | 12 inches | Rugged design, medium production runs, handles liquids, powders, granules |

Multilane Sachet Bagger | MSB 813mm | Up to 1000 | 8 inches | 12 inches | High output, small footprint, up to 20 lanes, fast and precise sealing, ideal for bulk packaging |

Companies like Syntegon Technology GmbH, Universal Pack, Marchesini Group, NJM Packaging, and SOMIC Packaging are top in this field. Their machines use automation, smart sensors, and better controls for accuracy. These companies spend money to make machines more flexible and easy to fix. HHZPACK makes powder sachet machines that help food companies work fast and fill each sachet right. Suden Machines give high filling accuracy, let you change speed, and seal well. This makes them good for many food jobs.

Tip: Multi-lane sachet packaging machines help food makers keep up with big orders. They also help cut down on waste and save time.

For Pharmaceuticals

Pharmaceutical companies need sachet packaging machines that are very accurate and clean. These machines must follow strict rules. Vertical packaging machines can pack liquids, powders, granules, and solids. They help save money and use space well. These machines can pack single doses and let you pick the size and amount.

Feature | Description |

|---|---|

Advantages | Lightweight, portable, single-serve packaging; excellent barrier protection; customizable shapes; cost-effective for mass production; ideal for precise dosage. |

Applications | Suitable for nutraceutical powders, electrolyte drinks, instant coffee & tea, enzymes, herbal supplements, creams, gels, honey, and syrups. |

Materials Used | Multilayer laminates such as PET/AL/PE, paper/poly/foil, and heat-sealable films. |

Machines Used | Vertical Form Fill Seal (VFFS), Stick Pack, Sachet Packing (3-side/4-side seal), multilane packing, auger or volumetric dosing systems. |

Regulatory Fit | Compliant with cGMP, HACCP, FDA, ISO22000; supports serialized coding and tamper-evidence. |

Common Variants | 3-side seal sachets, 4-side seal sachets, back seal sachets, center-seal sticks, twin-stick or dual chamber packs. |

Pharmaceutical sachet machines must meet ISO 15378, ISO 9001, CE, and FDA rules. These machines stop germs, are easy to clean, and track each sachet. Clean-in-Place systems and good checks help stop germs and keep the machines working right. Sachet materials must be safe for food and not have BPA. The seals must be strong to keep the product fresh.

Note: High-tech sachet packaging machines can print codes and show if a sachet was opened. This is important for safety and tracking in medicine.

For Liquids

Liquid products need sachet packaging machines that fill and seal well. Rotary Liquid Filling Machines, Vertical Form-Fill-Seal Machines, and Multi-Lane Liquid Sachet Machines fill each sachet with the right amount and stop leaks. These machines use strong valves and anti-drip parts to waste less. Stainless steel keeps things clean and safe.

High filling accuracy makes sure each sachet has the right amount.

Good sealing stops leaks from happening.

Automation uses touch screens, sensors, and finds problems fast.

Flexible designs fit many pouch sizes and materials.

Tier | Key Players | Technology Focus |

|---|---|---|

Nichrome India, Bosch Packaging Technology, Tetra Pak | Innovations like aseptic packaging, AI-driven predictive maintenance, recyclable pouch materials | |

Tier 2 | Viking Masek, GEA Group, Spack Machine | High-speed, customizable, modular solutions targeting mid-sized and regional markets |

Linpack is known for research and many types of machines, including ones that use special air to keep products fresh. The company gives custom solutions and has a good team for help and repairs. Linpack owns over 58 patents and all users are happy with their machines.

Good support after buying and the ability to change machines help companies keep working well and handle new needs.

Key Features

Filling Accuracy

Filling accuracy is very important for sachet packaging machines. Many things can change how well each sachet is filled. The measurement system, like piston or weight-based, helps with precision. The filling head design stops drips and clogs, so the amount stays the same. Liquids that are thick or thin need different ways to fill. Checking and fixing the machine often can make mistakes happen less, by up to 40%. Keeping the room at the right temperature and humidity helps make each sachet the same. Training workers and using clear steps also lowers mistakes. Companies use digital weighing and process control to watch accuracy. In food and medicine, being accurate keeps products safe and good.

Speed and Output

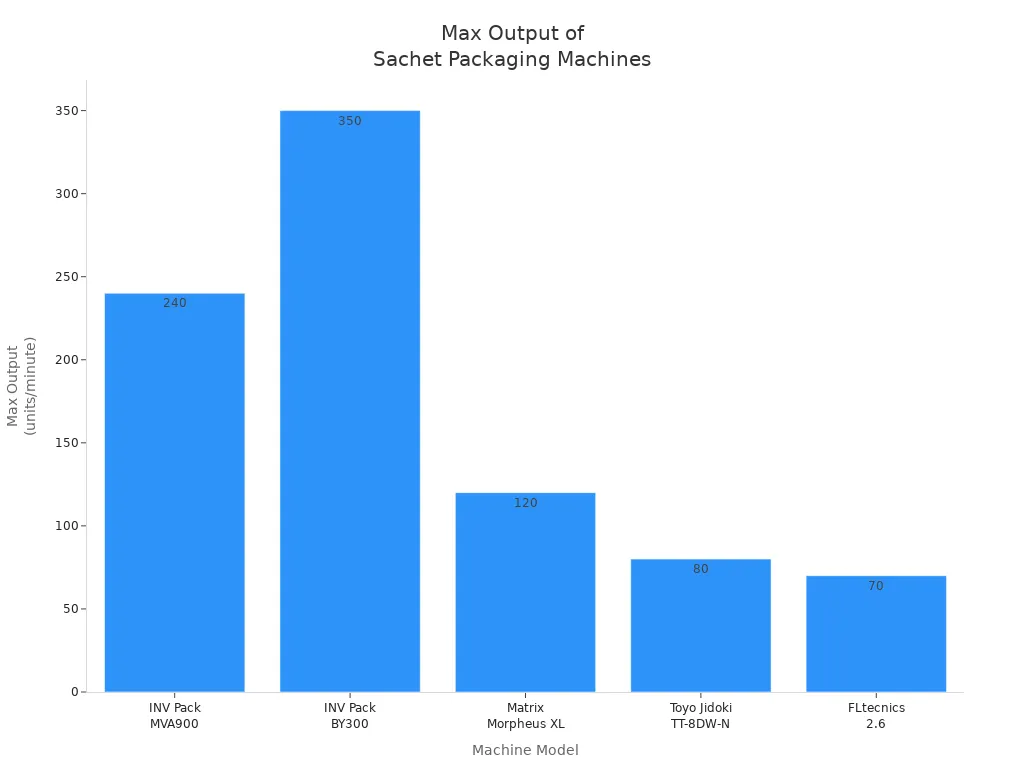

Speed and output show how many sachets a machine can make. New machines can make more or fewer sachets, based on their type. Some machines make up to 240 sachets each minute. Others make 150 to 350 stickpacks per minute. Some bag machines make over 120 bags every minute. High-speed pouch machines can make up to 80 pouches in one minute. Versatile pouch machines can make up to 70 pouches per minute. Picking the right speed helps companies reach their goals and keep quality high.

Machine Model | Type | Speed / Output Range |

|---|---|---|

INV Pack MVA900 | Multilane sachet | Up to 240 sachets per minute |

INV Pack BY300 | Multilane stickpack | 150–350 stickpacks per minute |

Matrix Morpheus XL | Bag machine | Over 120 bags per minute |

Toyo Jidoki TT-8DW-N | High-speed pouch | Up to 80 pouches per minute |

FLtecnics 2.6 | Versatile pouch | Up to 70 pouches per minute |

The right speed lets companies make enough sachets without losing quality.

Material Compatibility

Material compatibility means the machine works with many products and packages. The size, shape, and type of product help pick the right machine. Liquids need careful filling, but powders need special fillers. Fragile things need gentle handling so they do not break. Packages can be made from plastic, glass, metal, or soft films. Machines must fit these materials to stop damage and seal well. Clean machines are important, so many use stainless steel and easy-to-clean parts. Flexible machines can switch between materials fast and keep the quality good.

Automation

Automation helps sachet packaging machines work faster and need less hand work. Machines can be manual, partly automatic, or fully automatic. Smart automation uses AI to make changes as it works. Vision systems check for mistakes, and IoT lets people watch the machine from far away. These features make machines faster and more steady. They also lower mistakes and the need to fix things. Automation keeps workers safe by doing boring jobs for them. It lets companies make more sachets and use workers for harder jobs.

Maintenance

Good maintenance keeps machines working well and saves money. Moving parts need oil to stop rubbing and breaking. Cleaning the machine often stops dirt and hidden problems. Worn parts should be checked and changed before they break. Sensors, seals, and wires must work right for the machine to run well. Sometimes, experts should check the machine for bigger problems.

Doing regular maintenance means less downtime and longer machine life. It also costs less to fix. Workers who do basic care help the line run safely and smoothly.

Choosing a Sachet Packaging Machine

Product Type

Picking the right machine starts with knowing your product. Liquids, powders, and granules each need their own machine. The product’s form decides which machine works best. Look at the table to see which machine fits each product:

Product Type | Suitable Sachet Packaging Machine | Example Products |

|---|---|---|

Liquids and Pastes | Horizontal Sachet Packing Machines | Ketchup, shampoos, sauces |

Granules and Powders | Vertical Sachet Packing Machines | Sugar, salt, spices |

Single-serving narrow sachets | Stick Pack Machines | Coffee, drink mixes, supplements |

Sealing is important too. Three-side seals are good for small powder sachets. Four-side seals keep liquids and oily things safe. Back seals work for bigger items. The shape of the sachet and things like hanging holes can change what machine you need.

Production Needs

How much you need to make helps pick the machine. Small businesses can use semi-automatic or small automatic machines. Big factories need fast machines that make over 100 bags each minute. The table below shows which machine fits your production size:

Production Scale | Recommended Machine Type | Production Volume Threshold |

|---|---|---|

Small-scale production | Semi-automatic or small automatic machine | Market demand is low or not large |

Large-scale production | High-speed production packaging machine |

Tip: Companies should think about growing in the future. A flexible machine can help if you get more orders later.

Budget

Your budget affects what machine you can buy. Small machines cost less and fit in tight spaces. Big machines cost more but do more and make more sachets. The table below compares small and big machines:

Factor | Compact VFFS Machine | Big Size VFFS Machine |

|---|---|---|

Initial Cost | Lower, fits smaller budgets | Higher, needs more investment |

Facility Space | Compact, small facilities | Larger, big facilities |

Product Size | Smaller products | Larger products |

Production Volume | Lower volumes | Higher volumes |

Functionality | Basic features | Advanced, customizable |

Operation Complexity | Easier to use | More training needed |

You also need to pay for setup, training, and fixing the machine. Using more automation costs more at first but saves money on workers later.

The first price depends on size and features.

You will keep paying for repairs and new parts.

Custom and automatic features cost more but help you work better.

Compliance

Compliance keeps products safe and follows the law. Food and medicine packaging must meet strict rules. Companies should check for:

Packaging that does not react with the product.

Child-proof and tamper-proof features for safety.

Labels with product name, dose, lot number, and expiration date.

Good Manufacturing Practices (GMP) for quality and tracking.

Companies should also look at local laws, food-safe materials, and clean designs. Regular checks and audits help keep everything safe and legal.

Cost and ROI

Initial Investment

Sachet packaging machines cost a lot at first. Buyers need to think about the machine price and setup costs. The table below shows what small and medium businesses might pay:

Machine Type | Typical Price Range (USD) | Best For |

|---|---|---|

Semi-Automatic Premade Pouch Machines | $5,000 – $15,000 | Startups and small-batch producers |

Automatic Premade Pouch Machines | $25,000 – $80,000+ | Small to medium enterprises needing higher speed and consistent quality |

Shipping, setup, and training can add $2,500 to $10,000 or more. Companies should plan for these extra costs before buying a machine.

Operating Costs

Operating costs are the money spent to use a sachet packaging machine. Many things affect these costs:

Automatic machines use more power and need regular care, but they save money on workers because fewer people are needed.

Manual machines need more workers, so labor costs go up, but they use less power and cost less to fix.

Good machines usually cost 3% to 5% of their price each year for care. Cheaper machines may need 10% to 15% each year. Automatic machines use more power because they work faster and have more parts. Labor costs go down when machines do more work. How well the machine works and how much is wasted also change the total cost.

Tip: Taking care of machines and using them well helps stop surprise costs and keeps them working.

Long-Term Value

A sachet packaging machine can be worth more than its first price. Automation saves money on workers and materials. New machines use less packaging and power. Companies make products faster and have less waiting, so ROI gets better. For example, a $200,000 machine that brings in $150,000 each year pays for itself in about 1.3 years. This fast payback means good money returns. Being able to grow, making better products, and having a stronger brand also help. Waiting to use automation can make costs go up later. ROI math, like (Net Profit / Cost of Investment) x 100, helps companies see if they made a good choice. A good ROI means it is smart to buy new packaging machines.

Recommendations

Picking the right sachet packaging machine means knowing your product, how much you need to make, and your budget. Start by matching the machine to what you want to pack. Vertical form fill seal machines are good for powders and granules. Liquid sachet packing machines work best for sauces and gels. Multi-lane machines help when you need to make a lot at once. Stick pack machines are best for single-serve items.

The table below shows the best ways for each industry:

Industry/Sector | Product Types | Best Practices |

|---|---|---|

Food & Beverage | Powders, sauces, snacks | Use films that are safe for food, control portions, follow safety rules, and keep machines in good shape. |

Pharmaceuticals | Powders, gels, solutions | Follow GMP rules, use seals that show tampering, fill each sachet right, and get good help after buying. |

Personal Care | Shampoos, creams, gels | Pick machines that work with many films, fill gently, and let you add your brand. |

Agrochemicals | Pesticides, seeds | Choose materials that resist chemicals, seals that do not leak, and support close by. |

Household Chemicals | Detergents, cleaners | Use films that block leaks, make sure packaging does not leak, and train workers well. |

When picking a machine, think about these things:

How many sachets you need to make.

How well the machine fills each sachet.

If the machine works with your product’s material.

If the seals stop leaks.

How fast you can switch to new products.

If the machine is easy to use and saves on workers.

Tip: Buying a machine that can change for new products helps you keep up with the market.

It is important to balance price, features, and how much the machine will help you later. Look at the size, speed, and type of machine to fit your space and needs. Brands that cost more often give better help and break less. Machines that are easy to fix and have spare parts last longer. Training workers helps everything run smoothly. Think about all costs, like buying, fixing, and running the machine, to know its real value.

A good choice means you work faster, waste less, and keep your products good. Companies that check all these things make better choices and get more money back over time.

Picking the right Sachet Packaging Machine means knowing your product, how much you need to make, and your budget. You should look at features like UV sterilization, heat-sealing, and automation. These features help you work faster, save money, and keep quality the same.

Machines can pack powders, liquids, or granules, so they are flexible.

You can choose custom and eco-friendly options for different markets.

The comparison guide helps you match what you need with your budget and plans to grow.

If you check everything carefully, you will find the best machine for your business in the long run.

FAQ

What products can sachet packaging machines handle?

Sachet packaging machines can pack powders, liquids, granules, and pastes. They work for food, medicine, cosmetics, and chemicals. Each machine fits a certain product type.

How do companies choose the right sachet packaging machine?

Companies think about what they want to pack. They check how much they need to make. They look at their budget and safety rules. They compare machine speed and features. Picking the right machine helps work go faster and keeps products good.

How often should operators maintain sachet packaging machines?

Operators need to clean machines every day. They should check machines each week. Makers say to do bigger maintenance every few months. Regular care stops problems and helps machines last longer.

Are sachet packaging machines safe for food and pharmaceutical use?

Yes. Top machines use safe materials for food and medicine. They follow strict safety rules like GMP, FDA, and ISO. Good seals and clean parts keep products safe from germs.

Can one machine pack different sachet sizes?

Many new machines let you change sachet size and shape. Operators can switch products quickly. This helps companies meet new needs fast.